Ultrasonic fuel cell

A fuel cell and ultrasonic technology, used in fuel cells, fuel cell additives, circuits, etc., can solve problems such as failure, proton exchange membrane blockage, and reduced power conversion efficiency, and achieve large effects, prolong service life, and vibration energy. Low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

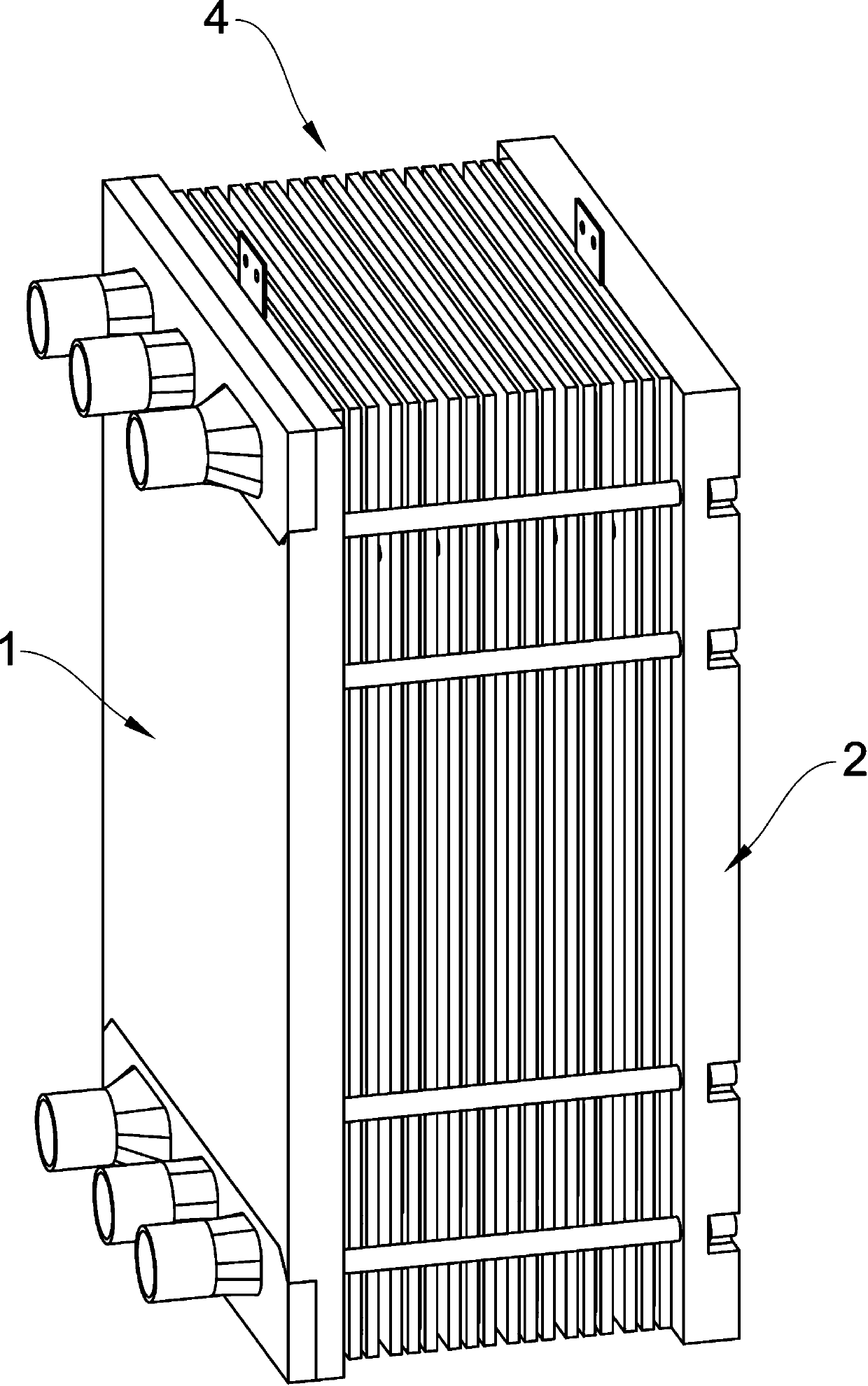

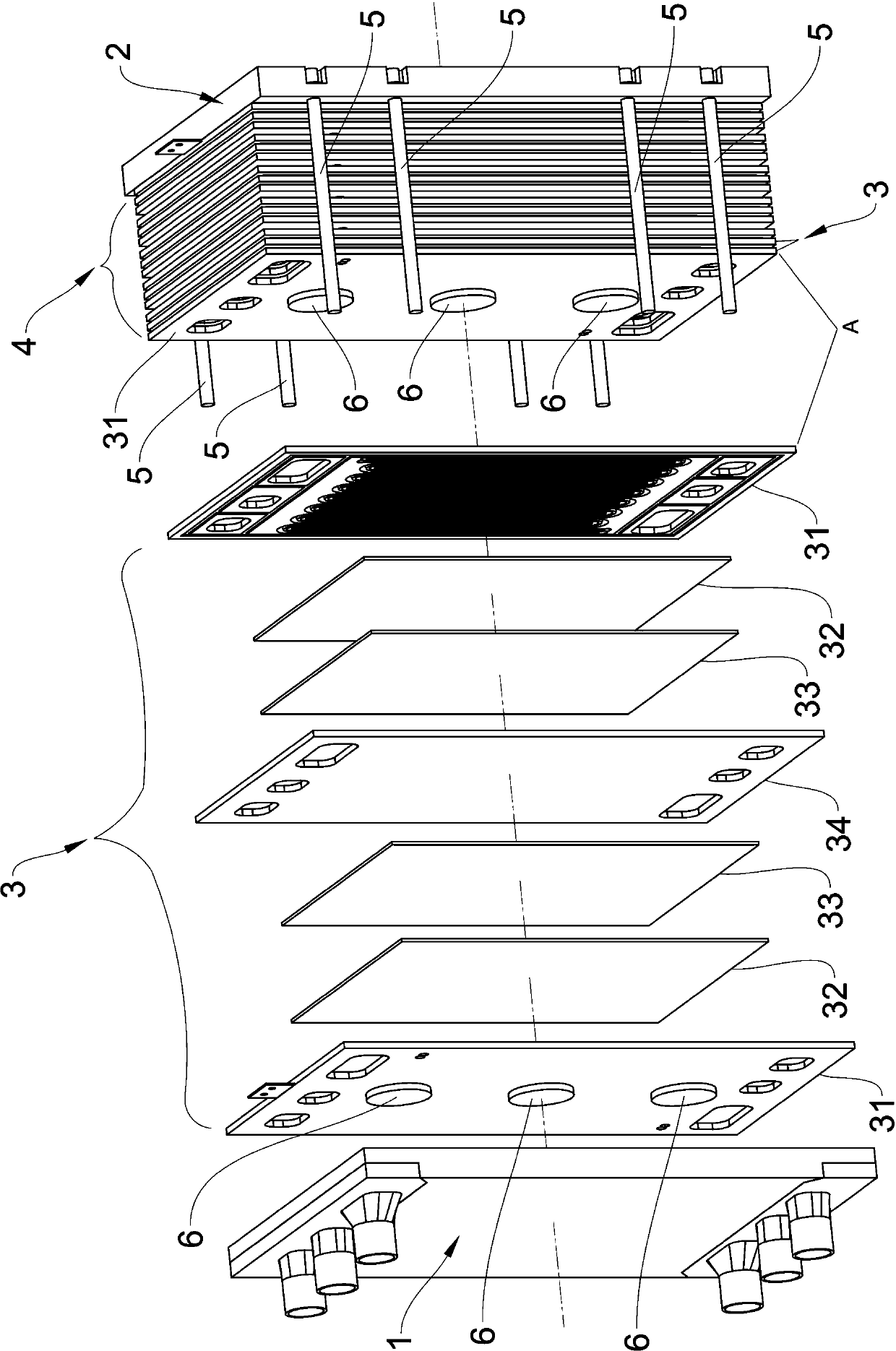

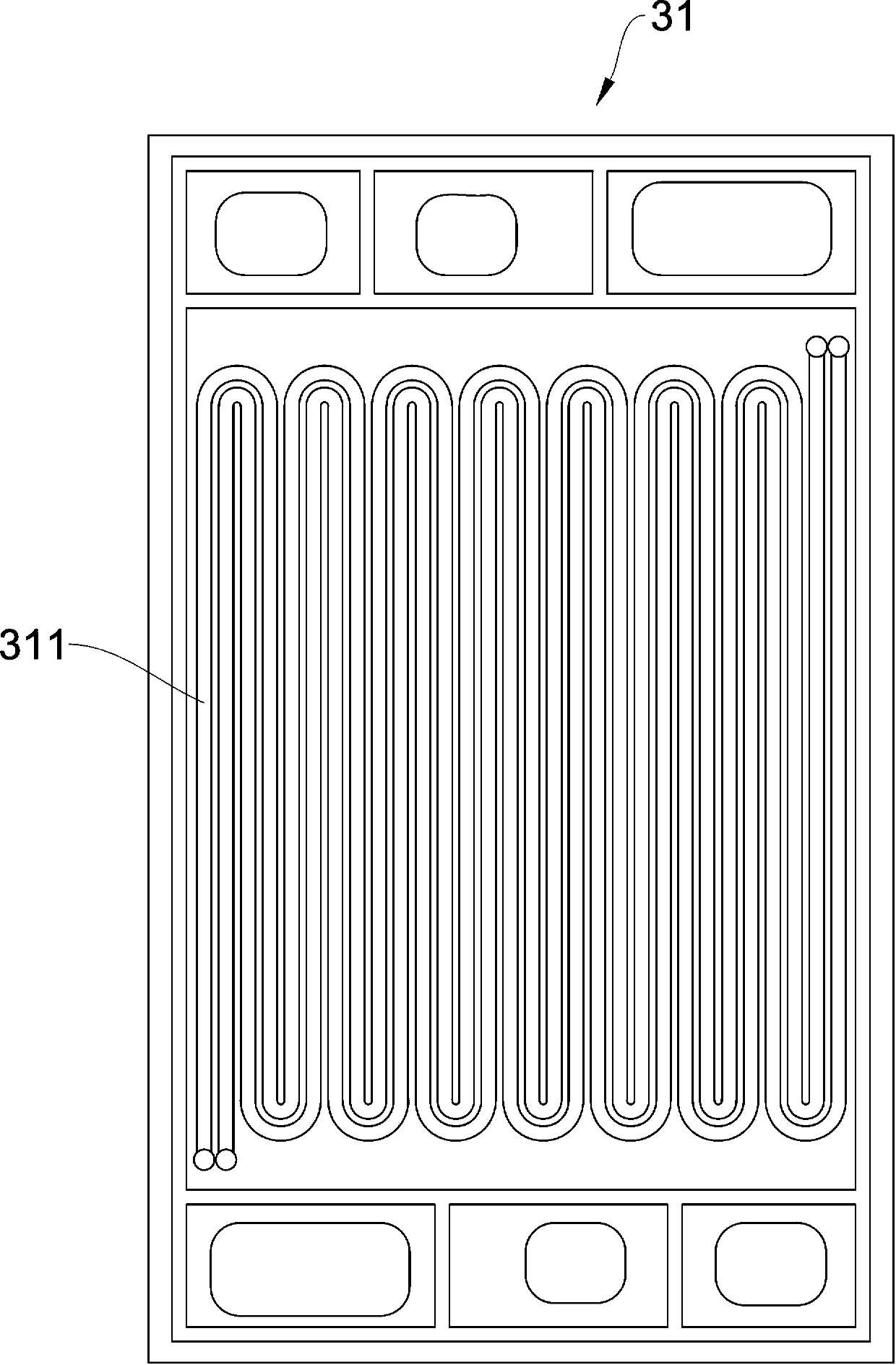

[0015] Such as figure 1 and figure 2 As shown, an ultrasonic fuel cell according to the present invention includes a front end plate 1, a rear end plate 2, an electric stack 4 and a screw 5 formed by stacking and combining several single cells 3 in series, wherein the electric stack 4 Arranged between the front end plate 1 and the rear end plate 2 and fastened by the screw 5, the single battery 3 is sequentially composed of a bipolar plate 31, carbon paper / carbon cloth 32, a catalyst sheet 33, a proton exchange Membrane 34 , catalyst sheet 33 , carbon paper / carbon cloth 32 , and bipolar plate 31 are stacked. The structural principle of this part is basically consistent with the existing fuel cells, and will not be described in detail here. In order to realize the purpose that the present invention proposes, as figure 2 , Figure 4 As shown, the outer side of the single battery 3 is located on the back of the bipolar plate 31 and several ultrasonic transducers 6 are also ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com