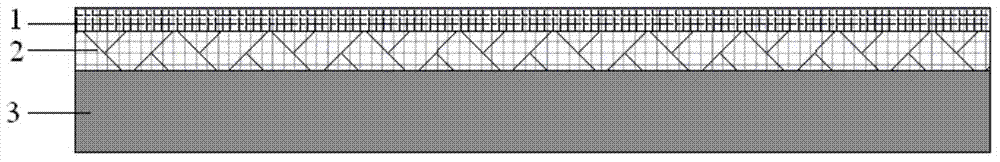

Modified manganese dioxide catalyst, modified manganese dioxide catalyst electrode and preparation method of modified manganese dioxide catalyst and modified manganese dioxide catalyst electrode

A technology of manganese dioxide and nano-manganese dioxide, which is applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve short service life and low anode current efficiency and other problems, to achieve the effect of low price, improved conductivity and stability of crystal structure, and refined grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

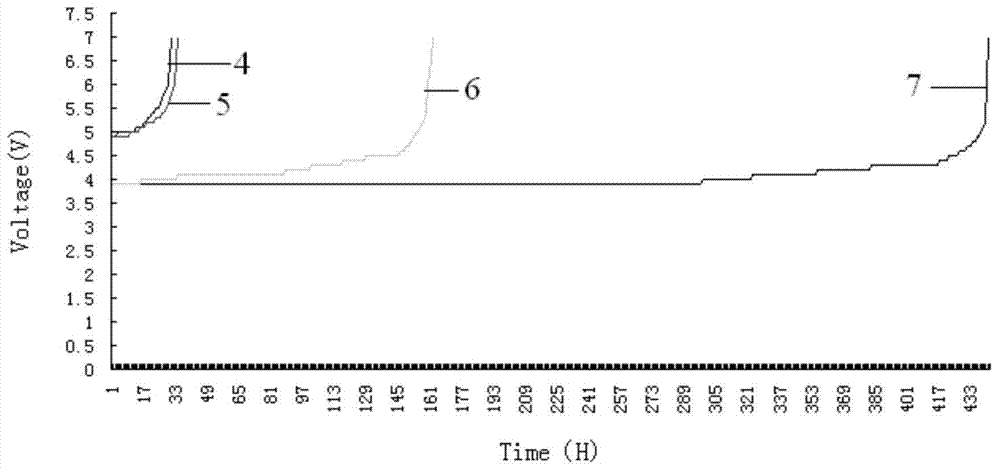

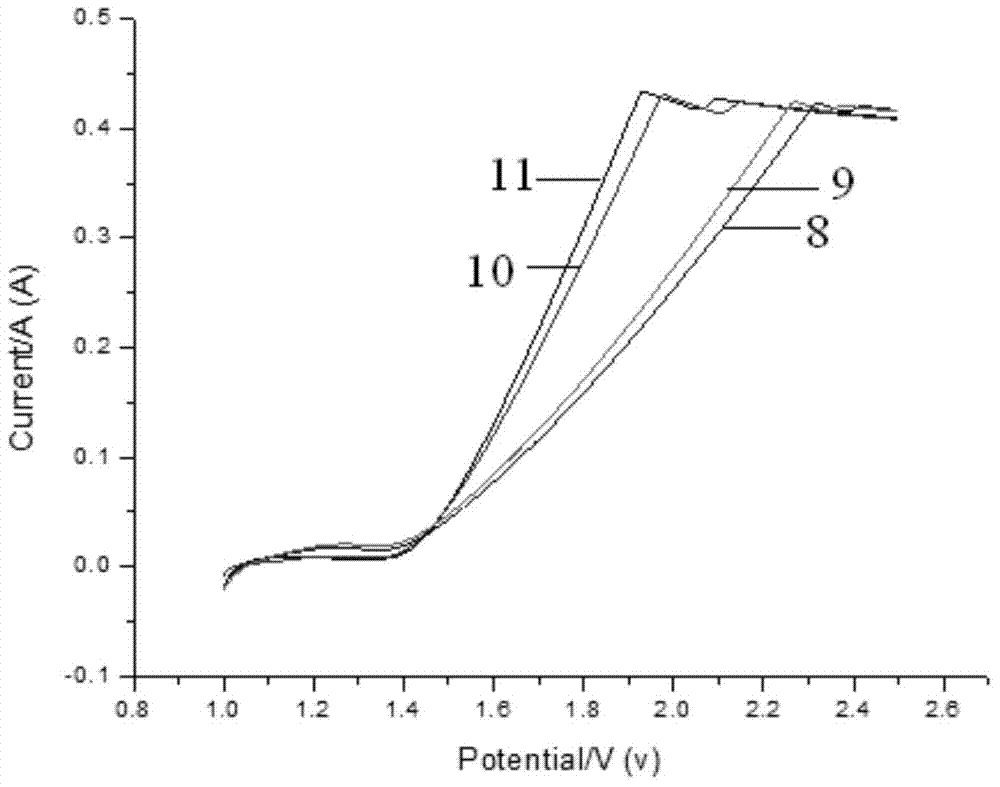

Examples

Embodiment 1

[0056] (1) Process the grade as TA1 so that the effective area of the end is 2cm 2 of long strips. After degreasing and corundum sandblasting on the surface, clean it with water and soak it in 3% oxalic acid solution for use;

[0057] (2) Put Ti 4 o 7 (45%) and Ti 5 o 9 (35%) titanium dioxide powder with a total crystal content of 80% is pretreated. The treatment process is to first soak in nitric acid with a concentration of 3mol / L, wash with water until neutral, and repeat the soaking and washing process 3 times to fully remove acid-soluble impurities; then soak in 5mol / L sodium hydroxide solution, and wash with water until neutral. Neutral, repeat the soaking and washing process 3 times to fully remove alkali-soluble impurities; finally wash 3 times with acetone to remove organic matter; vacuum dry, pass through a 300-mesh sieve, and set aside.

[0058] (3) After the titanium plate soaked in the oxalic acid solution was cleaned and dried at 100° C., the surface was ...

Embodiment 2

[0074] (1) Process the grade as TA1 so that the effective area of the end is 2cm 2 of long strips. After degreasing and corundum sandblasting on the surface, clean it with water and soak it in 5% oxalic acid solution for use;

[0075] (2) Put Ti 4 o 7 (40%) and Ti 5 o 9(35%) TiO2 powder with a crystal content of 75% was pretreated. The treatment process is to soak in nitric acid with a concentration of 2.5mol / L, wash with water until neutral, and repeat the soaking and washing process 4 times to fully remove acid-soluble impurities; then soak in 4mol / L alkaline solution, wash with water until neutral and repeat the soaking and washing process 5 times to fully remove alkali-soluble impurities; finally wash 2 times with acetone to remove organic matter; vacuum dry, pass through a 300-mesh sieve, and set aside.

[0076] (3) After cleaning and drying the titanium plate soaked in the oxalic acid solution, the surface is subjected to corundum sandblasting treatment. Dry the...

Embodiment 3

[0083] (1) Process the grade as TA1 so that the effective area of the end is 2cm 2 of long strips. After degreasing and corundum sandblasting on the surface, clean it with water and soak it in 2% oxalic acid solution for use;

[0084] (2) Put Ti 4 o 7 (40%) and Ti 5 o 9 (40%) Titanium oxide powder with a crystal content of 80% was pretreated. The treatment process is to soak in nitric acid with a concentration of 2mol / L, wash with water until neutral, and repeat the soaking and washing process 3 times to fully remove acid-soluble impurities; then soak in 5mol / L alkaline solution, and wash with water until neutral , and repeat the soaking and washing process 3 times to fully remove alkali-soluble impurities; finally wash 3 times with acetone to remove organic matter; vacuum dry, pass through a 300-mesh sieve, and set aside.

[0085] (3) After cleaning and drying the titanium plate soaked in the oxalic acid solution, the surface is subjected to corundum sandblasting trea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com