Metal carbon tube component for purifying wastewater and electrocatalytic oxidation device

A technology of electrocatalytic oxidation and metal components, applied in the direction of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of high cost of treatment equipment investment, depreciation and maintenance, complex treatment process, and small treatment capacity and other problems, to achieve the effect of long-term stable and effective operation, improved reaction efficiency, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

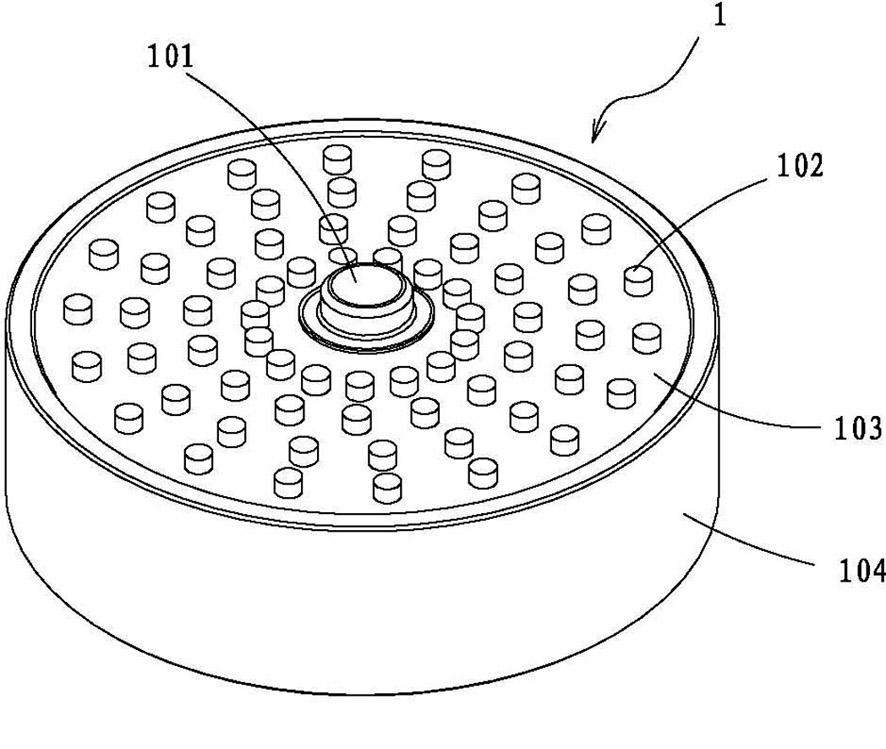

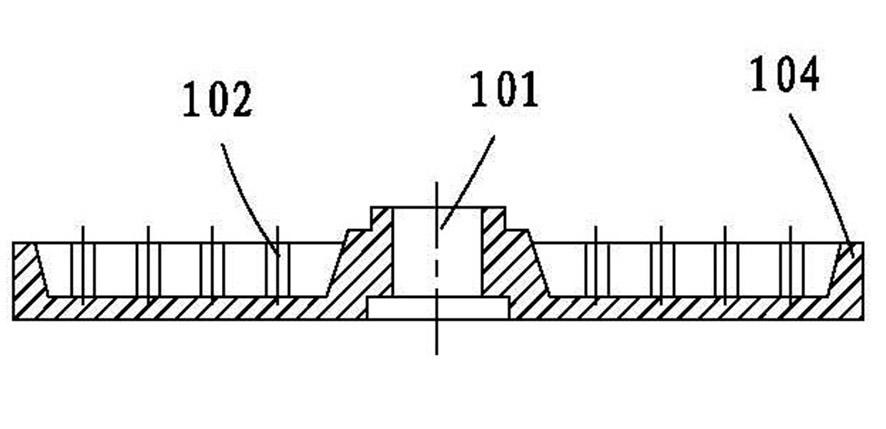

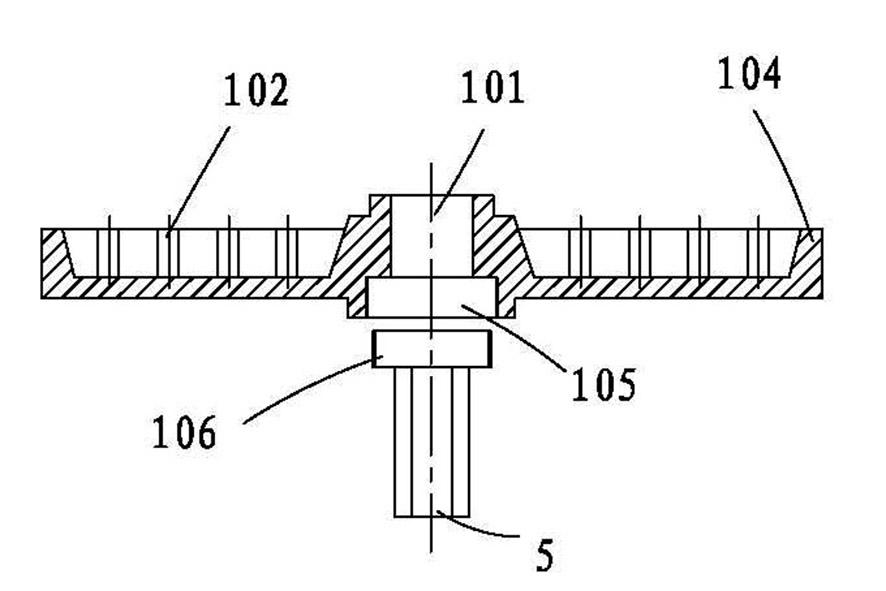

[0055] see Figure 1-Figure 5 , the present invention firstly provides a metal carbon tube assembly 1 for purifying high-concentration organic wastewater such as landfill leachate NF and RO membrane concentrate, which includes a metal disc 104 and at least one center pipe 101, and the center pipe 101 The side wall is provided with a plurality of evenly distributed first through holes (not shown in the figure), and each first through hole is formed during processing and arranged radially along the side wall of the central tube 101 . The central tube 101 is placed in the center of the inner cavity of the metal disc 104 with one end closed, and can be integrally formed with the metal disc 104. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com