Preparation method and application of nitrogen-doped zero-valent iron composite material

A composite material, zero-valent iron technology, applied in the field of environmental chemistry, can solve the problem of toxic by-products such as dichloroethylene, and achieve the effects of overcoming the passivation problem, high removal efficiency, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The nitrogen-doped zero-valent iron material is prepared by a planetary ball mill, and the specific steps are as follows: zirconia ball milling beads (6mm in particle size) with 20% of the cavity volume are loaded into the ball mill tank; 0.046g of melamine powder and 2.454g of reduced iron powder are weighed (Nitrogen-iron mass ratio is 1:53.35) placed in the ball mill tank, and filled with argon in the tank; the ball mill speed was adjusted to 400rpm, and ground for 20 hours; under nitrogen atmosphere, the ground product and the grinding medium were separated by a screen separation to obtain a nitrogen-doped zero-valent iron composite material.

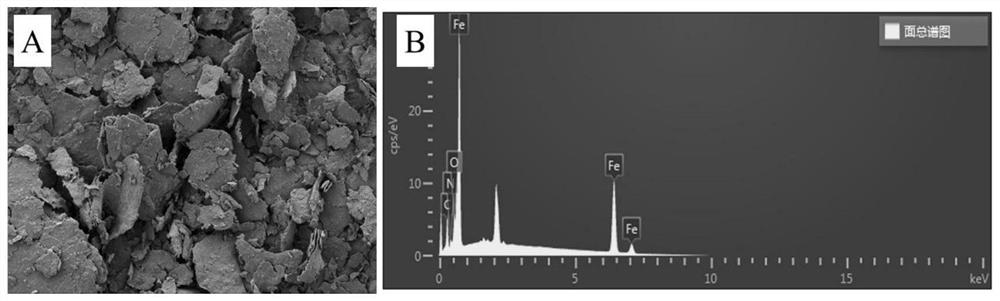

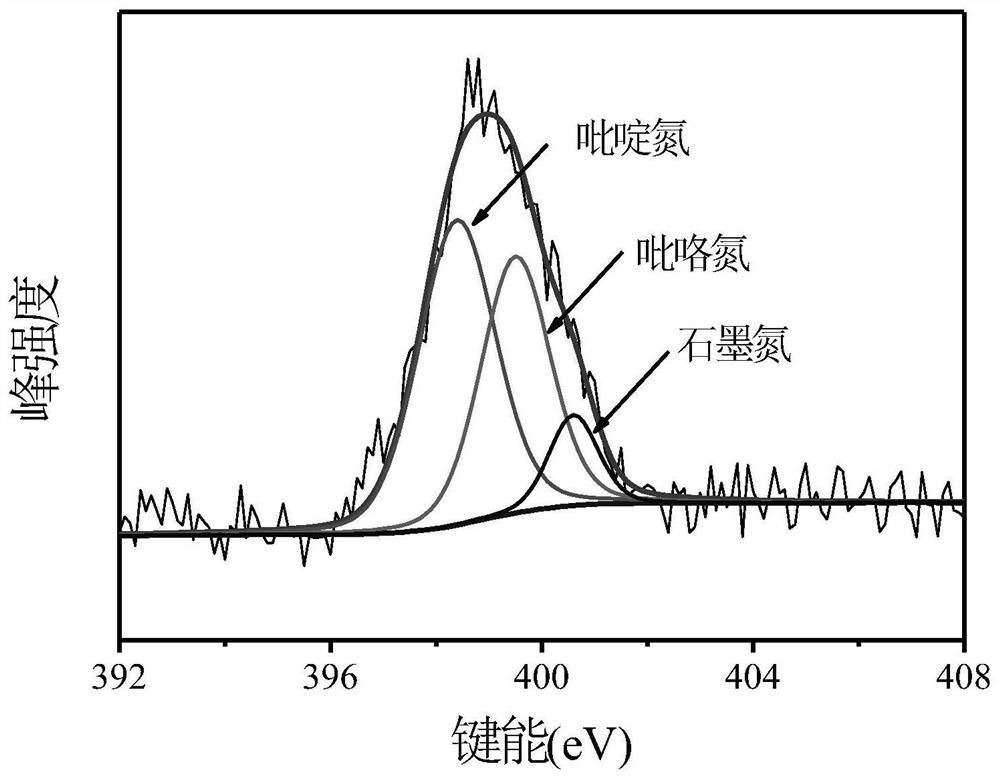

[0040] figure 1 , 2 They are the SEM-EDS diagram and the XPS diagram of the nitrogen-doped zero-valent iron composite material prepared in this example, respectively. From figure 1 It can be seen that its structure is a flaky structure, and it can be clearly seen that there is nitrogen in the material, indicating that mela...

Embodiment 2

[0045] The nitrogen-doped zero-valent iron material is prepared by a planetary ball mill, and the specific steps are as follows: zirconia ball milling beads (6 mm in particle size) of 20% cavity volume are loaded into the ball mill jar; 0.090 g of melamine powder and 2.410 g of reduced iron powder are weighed (mass ratio of nitrogen to iron is 1:26.78) placed in a ball mill tank, and filled with argon in the tank; the ball mill speed was adjusted to 400rpm, and ground for 20 hours; separation to obtain a nitrogen-doped zero-valent iron composite material.

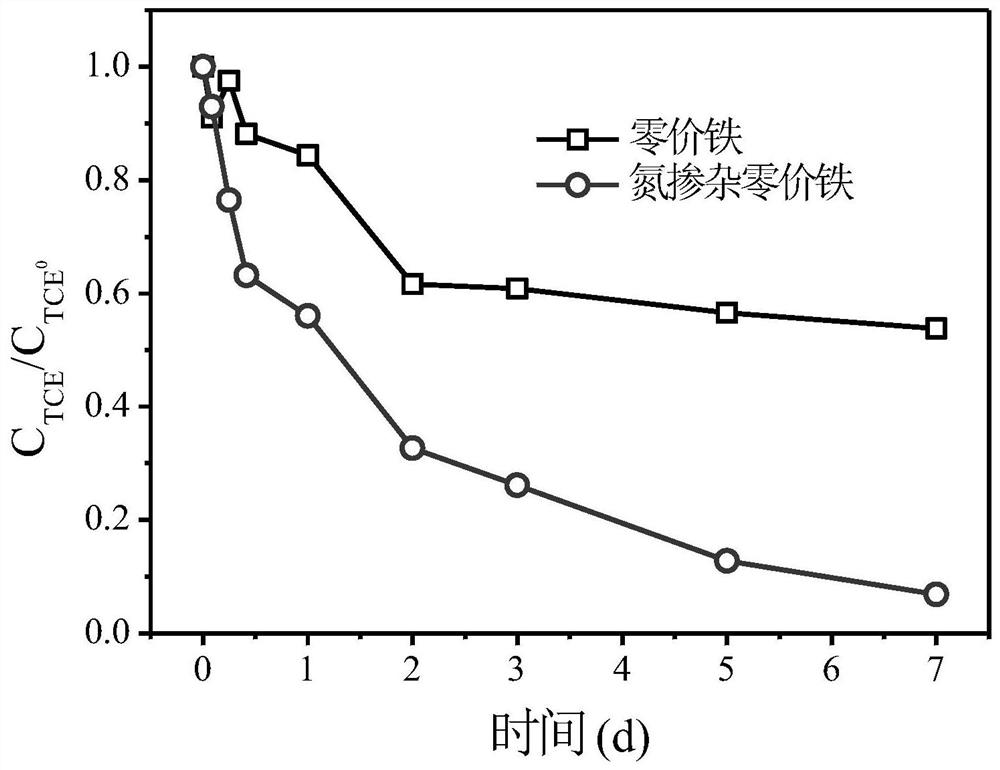

[0046] Taking trichlorethylene as the target pollutant, the activity of the above materials was investigated. Add 0.26 g of nitrogen-doped zero-valent iron composite to a 52 mL serum bottle, add 26 mL of deoxygenated pH buffer solution (50 mM HEPES, pH=7.0), cap tightly with an aluminum cap with a PTFE septum, then add trichlorethylene stock solution to ensure that the initial concentration of trichlorethylene is 10ppm, an...

Embodiment 3

[0050] The nitrogen-doped zero-valent iron material was prepared by a planetary ball mill, and the specific steps were as follows: zirconia ball milling beads (6mm in particle size) with 20% cavity volume were loaded into the ball mill tank; 0.242g of urea powder and 2.258g of reduced iron powder were weighed (Nitrogen-iron mass ratio is 1:9.33) placed in the ball mill tank, and filled with argon in the tank; the ball mill speed was adjusted to 400rpm, and ground for 20 hours; under nitrogen atmosphere, the ground product and the grinding medium were separated by a sieve separation to obtain a nitrogen-doped zero-valent iron composite material.

[0051] Taking trichlorethylene as the target pollutant, the activity of the above materials was investigated. Add 0.26 g of nitrogen-doped zero-valent iron composite to a 52 mL serum bottle, add 26 mL of deoxygenated pH buffer solution (50 mM HEPES, pH=7.0), cap tightly with an aluminum cap with a PTFE septum, then add trichlorethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com