Super-hard blade passivation polishing machine

A superhard blade and polishing machine technology, which is applied in the field of polishing machines, can solve the problems of poor blade edge condition, low efficiency of manual passivation, and low service life, and achieve the problem of blade edge passivation, compact structure, and high efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

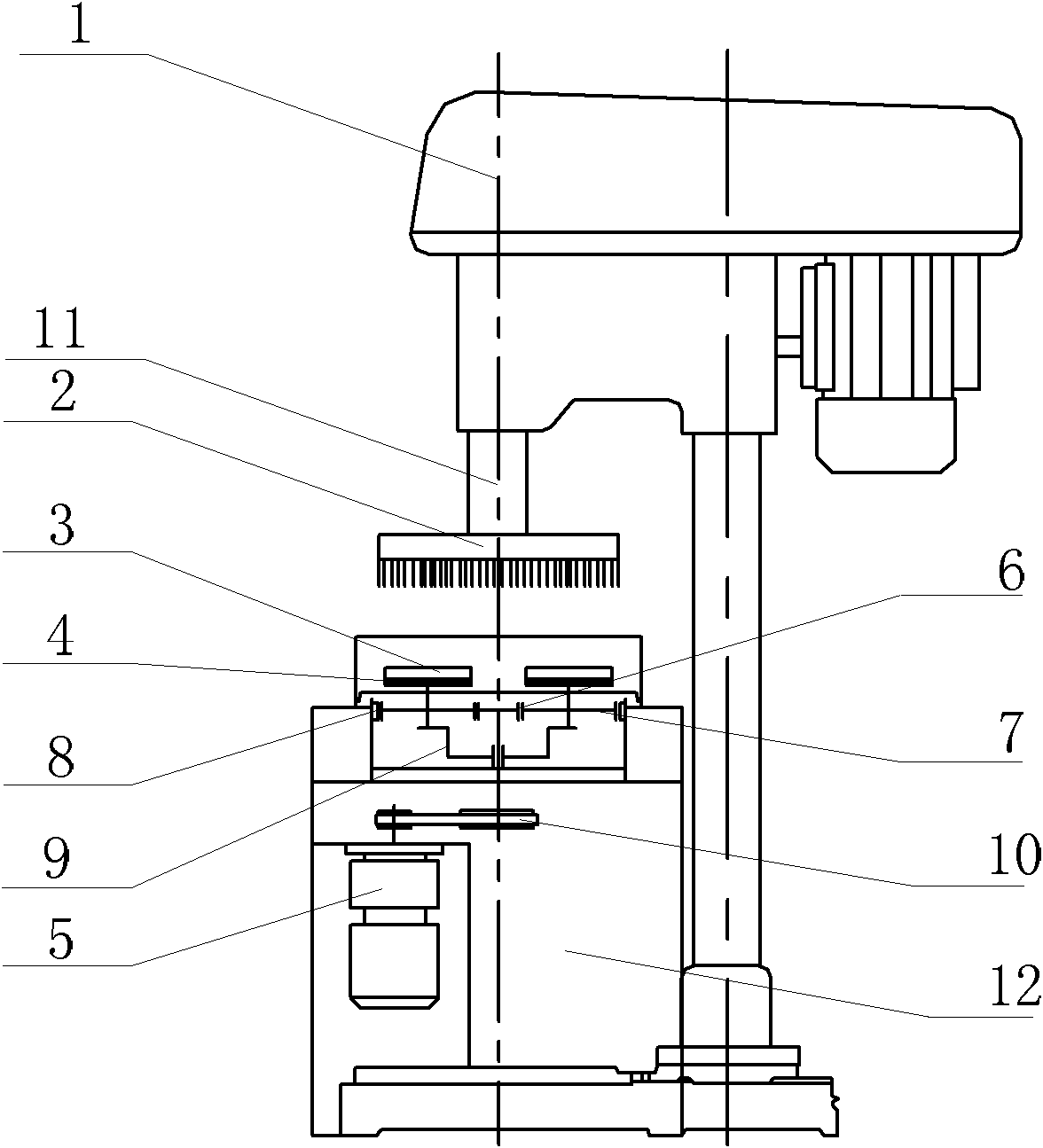

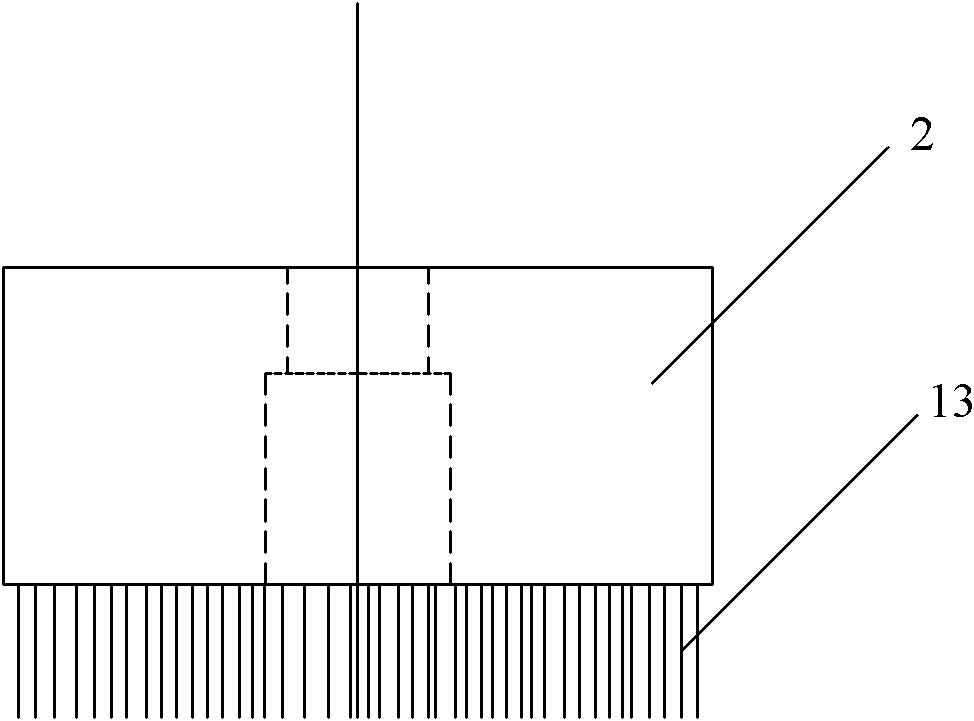

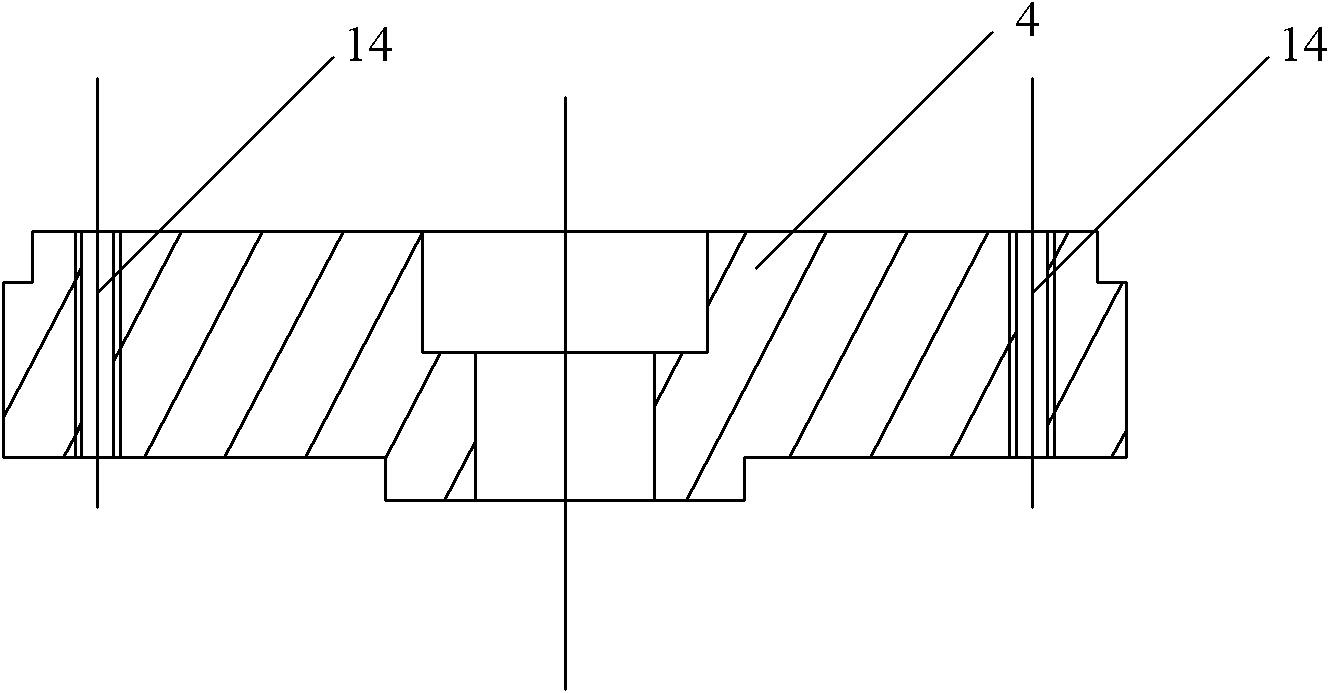

[0015] After the edge passivation and surface polishing treatment of the superhard insert, it can enhance the cutting performance and prolong the service life. In this embodiment, the superhard blade passivation polishing machine reformed with the West Lake bench drill is specially used for passivation and surface polishing of the blade. Its structure is as follows figure 1 As shown, it includes the West Lake bench drill 1, the brush disc 2 installed on the main shaft 11 of the West Lake bench drill 1, the base 12, the planet carrier 9 with the planetary gear transmission structure installed, the blade turntable 4, the blade container disc 3 and the speed control Motor 5. The base 12 is arranged directly under the brush plate 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com