Nitrogen and phosphorus removal water treatment device and treatment method thereof

A technology of water treatment device and sewage treatment method, which is applied in the fields of special compound water treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

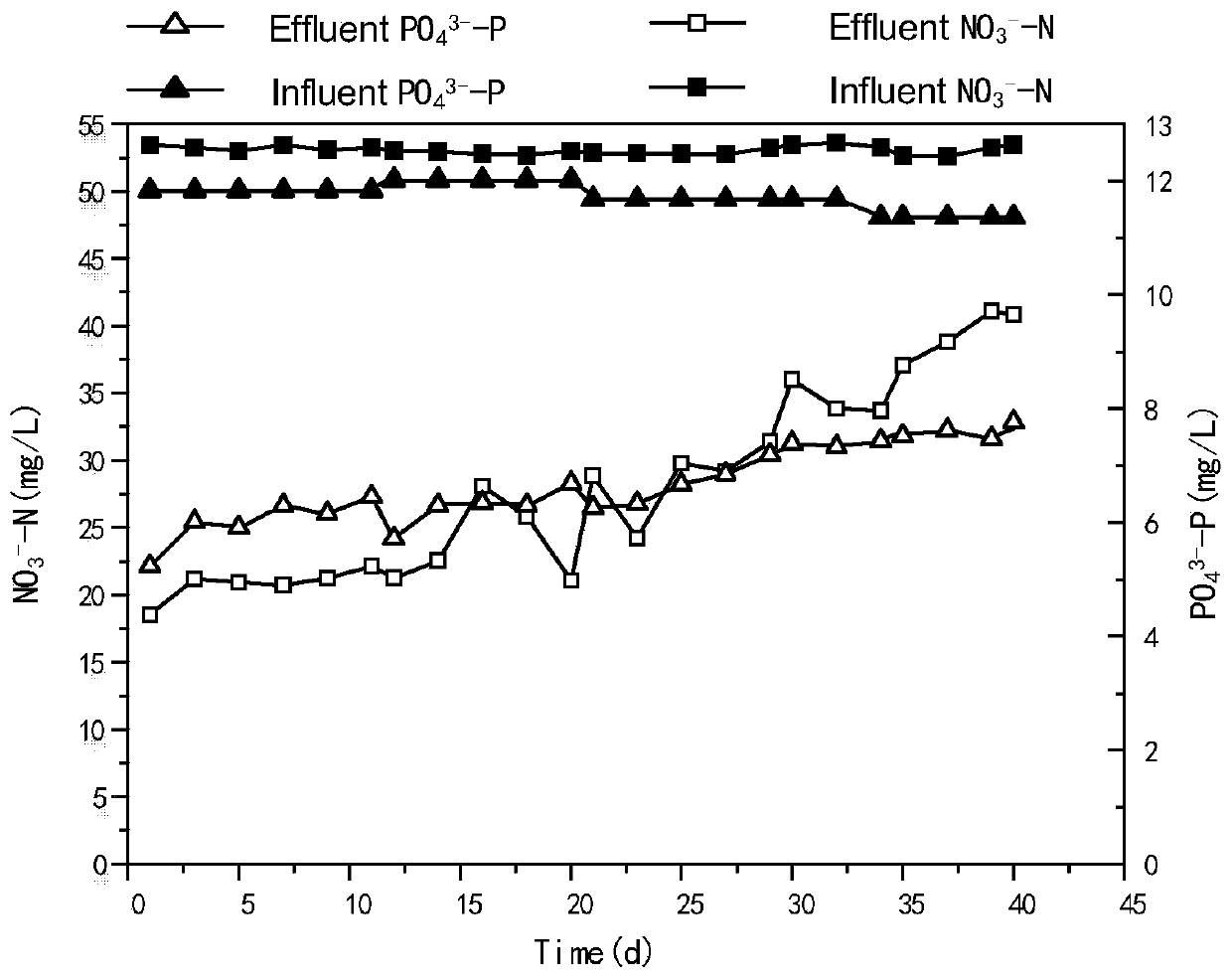

Embodiment 1

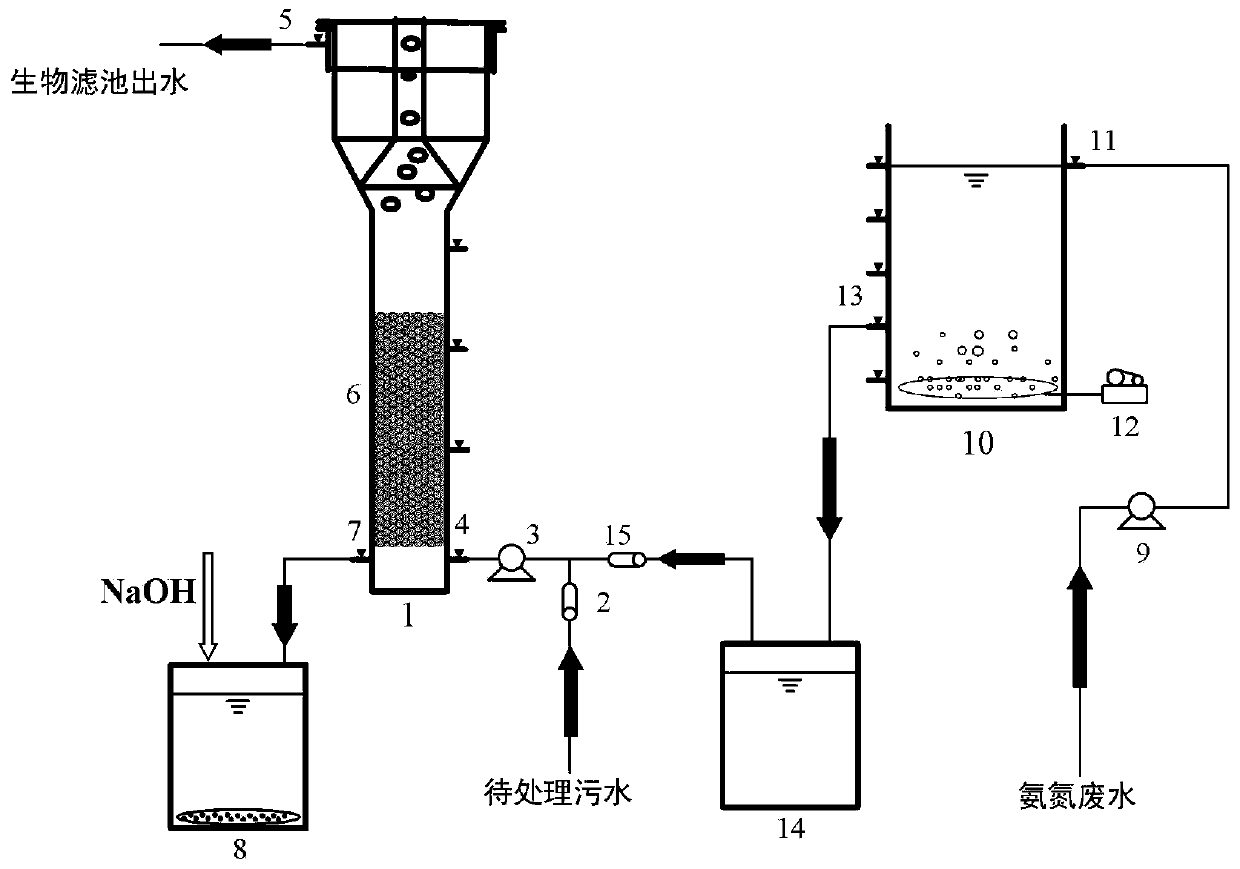

[0029] The experimental device adopted by the sewage treatment method of the present invention is as figure 1 As shown, the water treatment device of the present invention includes a biofilter 1 and a nitrification reaction tank 10; a pyrite filler 6 is filled in the biofilter 1, and an activated sludge microbial film is attached to the surface of the pyrite filler 6; the biofilter 1 is equipped with water inlet I4, water outlet I5 and water outlet II7 (the water inlet I4, water outlet I5 and water outlet II7 are all equipped with valves), and the water inlet I4 of biological filter 1 is connected to two water inlet branches. The water inlet branch passes the sewage to be treated into the biofilter 1 through the water inlet pump I3, and the second water inlet branch connects with the nitrification reaction liquid storage tank 14 through the water inlet pump I3, and the first water inlet branch and the second water inlet branch are both There are switches (respectively switch 2...

Embodiment 2

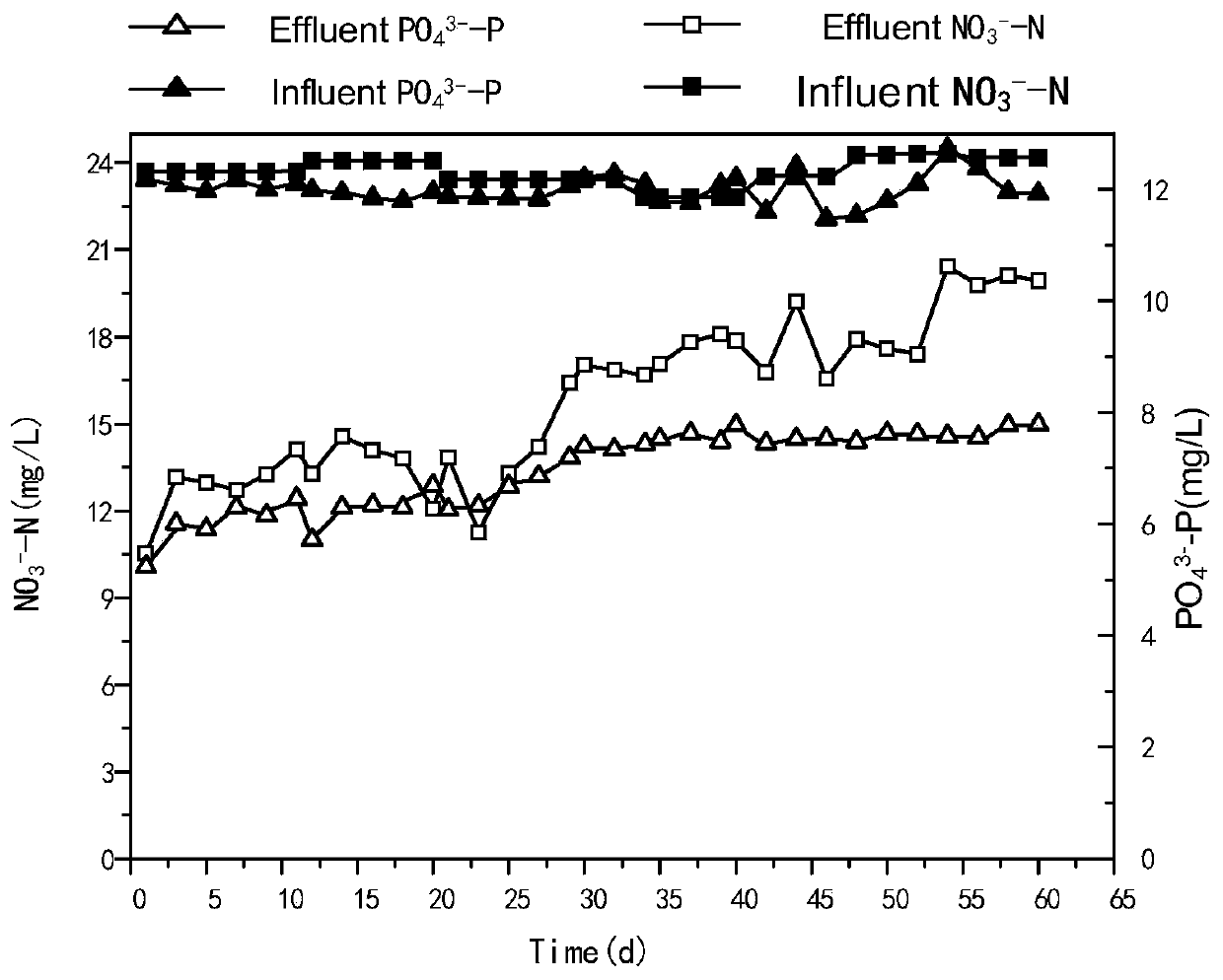

[0036] The sewage treatment method of the present embodiment, the basic process is the same as that of the embodiment 1, the difference is that in the step 1 of the present embodiment, the influent NO 3 - -N concentration is 21.88mg / L, PO 4 3- -P concentration is 12.31mg / L, the hydraulic retention time of sewage to be treated in biofilter 1 is 48h, the result is as follows image 3 Shown, the measured water NO 3 - -N and PO 4 3- -P concentrations were 8.67mg / L and 6.15mg / L, respectively. After biofilter 1 has been in operation for 60 days, the removal rate of nitrate nitrogen in biofilter 1 is only 12.49%. At this time, the surface of pyrite filler is passivated; in step 2, the concentration of ammonia nitrogen in ammonia nitrogen wastewater is 47.89mg / L, and the nitrification reaction The hydraulic retention time of ammonia nitrogen wastewater in pool 2 is 24h, and the pH of the effluent is 5.2; in step 3, pickling pyrite is soaked in an acid solution with a pH of 5.2 ...

Embodiment 3

[0038] The sewage treatment method of the present embodiment, the basic process is the same as the embodiment 1, the difference is that in the step 2 of the present embodiment, the concentration of ammonia nitrogen in the ammonia nitrogen wastewater is 50mg / L, and the hydraulic retention time of the ammonia nitrogen wastewater in the nitrification reaction tank 2 is 72h, The pH of the effluent was 4.9; in step 3, pickling the pyrite was soaked in an acid solution with a pH of 4.9 for 24 hours, and 1.14 g of precipitate was recovered from the washing liquid recovery pool 8, and the recovery rate of total phosphorus was 66.22%.

[0039] The sewage treatment process of the present invention first adopts pyrite autotrophic denitrification to simultaneously remove nitrogen and phosphorus in water; then utilizes nitrification reaction to produce acid, and finally utilizes the acid solution generated by nitrification reaction to carry out pickling regeneration on the passivated pyrite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com