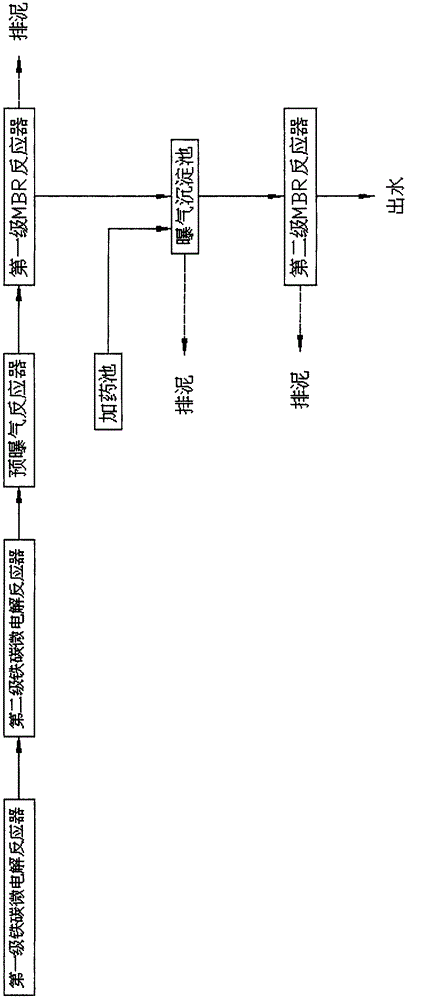

Technology and device for treating percolate from small rubbish transfer station

A technology of waste transfer station and treatment process, which is applied in the field of leachate treatment process and device of small waste transfer station, can solve the problems of large space occupation, high process operation requirements, large floor area, etc., and achieves cost saving and simplified process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

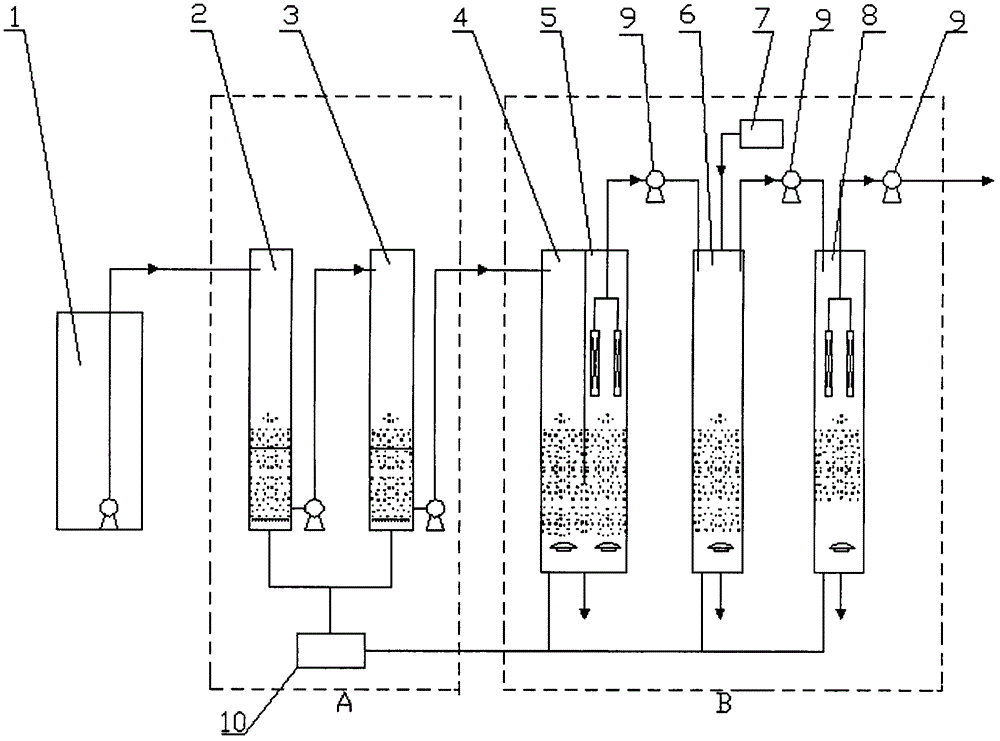

Embodiment Construction

[0021] The leachate from the garbage transfer station collected by the collection pool 1 is directly pumped into the first-stage iron-carbon micro-electrolysis reactor 2, and the effluent is then pumped into the second-stage iron-carbon micro-electrolysis reactor 3. Due to the water quality characteristics of the leachate of the garbage transfer station is relatively acidic (pH=3~5), the reaction time of the micro-electrolysis needs to be controlled during the two-stage iron-carbon micro-electrolysis reaction process, and the reaction time is controlled within 1-2h. Gradually increase the pH of the system, and control the iron-carbon filling ratio to 50%-80%, so that part of the iron element enters the next functional section. The effluent of the second-stage iron-carbon micro-electrolysis reactor 3 enters the pre-aeration tank 4, and by controlling the aeration rate of the pre-aeration tank 4, the gas-water ratio of the two-stage iron-carbon micro-electrolysis is controlled to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com