Device and method for processing semiconductor material through backward multifocal lasers and electrochemistry in combined manner

A composite processing and semiconductor technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as uneven distribution of porosity, increased control distance between light source and sample, and inability to guarantee light intensity. Good precision, avoid the taper of the hole wall, and improve the processing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

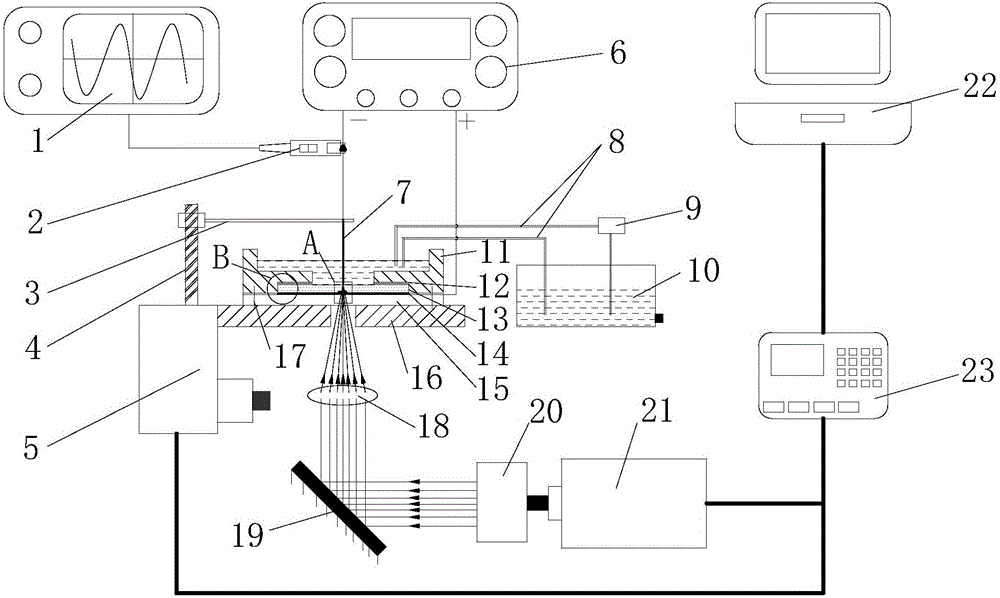

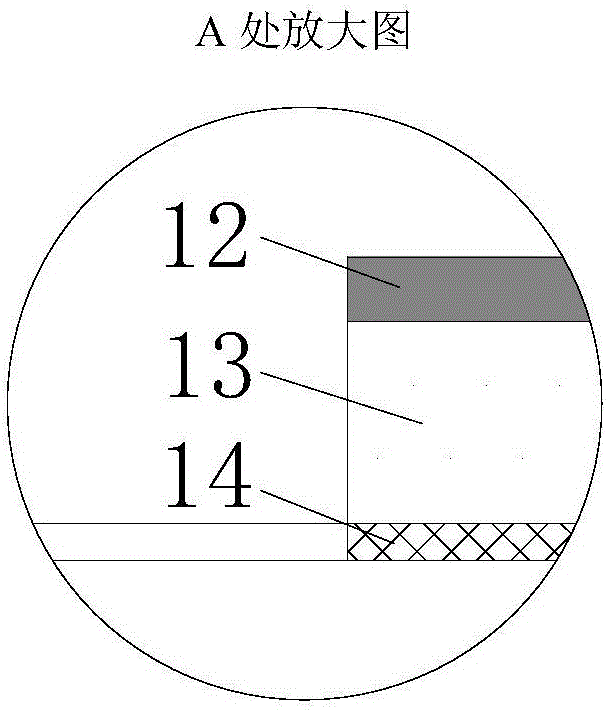

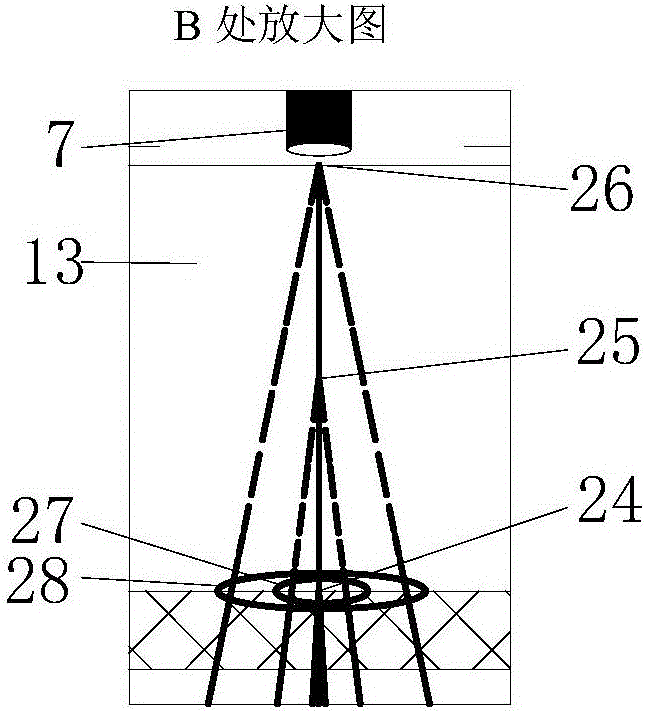

[0036] Such as figure 1 The shown laser multi-focus and electrochemical compound processing device for semiconductor materials mainly includes a multi-focus laser irradiation system, an electrochemical reaction system, an electrolyte circulation system and a motion control system.

[0037] Described motion control system mainly comprises computer 22, control cabinet 23, numerical control platform 5, and computer 22 links to each other with control cabinet 23, and control cabinet 23 links to each other with numerical control platform 5, and control cabinet 5 links to each other with pulsed laser 21, and computer 22 connects to each other through control cabinet 23. Control the movement of the numerical control platform 5 . A through hole is provided at the center of the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com