Formation method for flexibly-packaged power lithium-ion battery

A technology of lithium-ion battery and formation method, which is applied in the field of formation process of high-energy-density pouch power lithium-ion battery, which can solve the problems of incomplete electrochemical reaction, poor wettability between pole piece and electrolyte, etc., and achieve sufficient wettability , Increase the formation pressure and increase the effect of wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

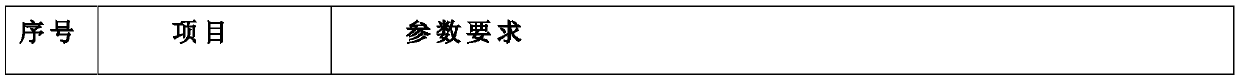

[0033] Inject liquid into the cell, and let the cell stand for 8 hours. Pre-seal the edge, put the cell vertically into the pressure fixture, and charge it according to the following process:

[0034]

[0035] Two seals at a time, vacuum degree ≤ -70KPa. At 35°C, place the cells horizontally for 24 hours.

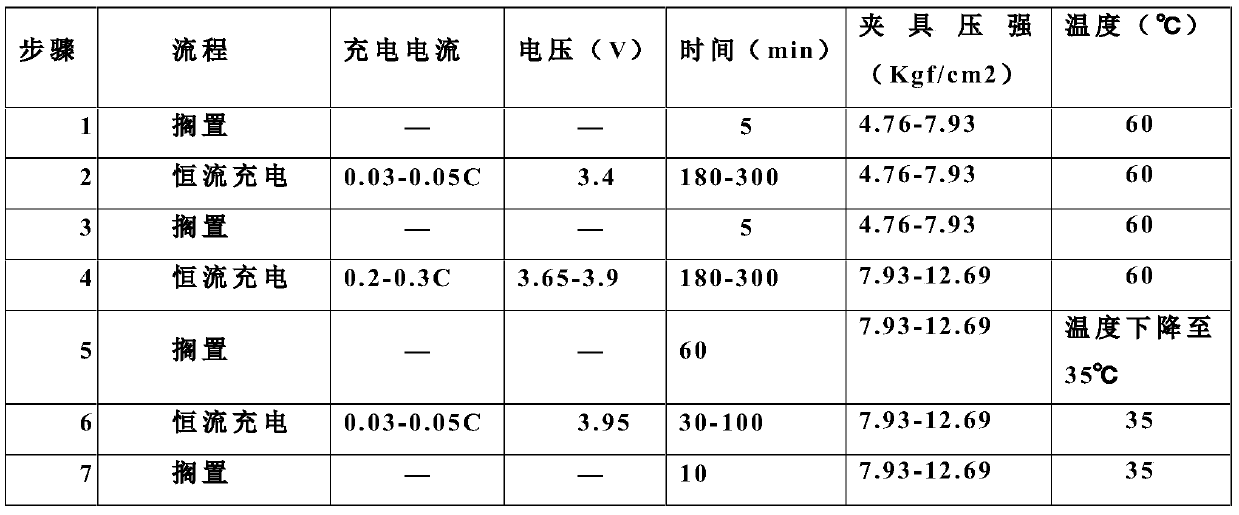

[0036] Preferably, the steps of secondary pressurized normal temperature charging are as follows:

[0037]

[0038] The parameter requirements of the second and second sealing, the packaging strength is ≥50N / 15mm, and the packaging vacuum is ≤-70KPa.

[0039] The same batch of batteries was randomly divided into two groups, one group was formed by high temperature and normal pressure (existing process)-group A, and one group was obtained according to Example 1 of the present invention-group B, each group had 40 PCS.

[0040]

Embodiment 2

[0042] Same as Example 1, the difference is that the cell is left to stand for 12 hours after liquid injection.

Embodiment 3

[0044] With embodiment 1, the difference is that the steps of charging are as follows:

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com