Preparation method of hollow biconical micro-nano structure spinel lithium manganate cathode material

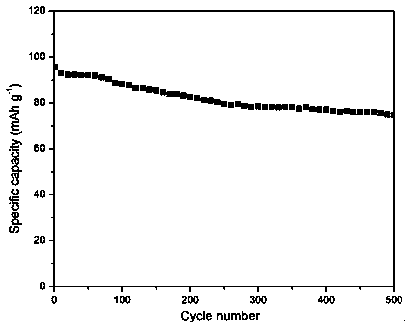

A technology of micro-nano-structured lithium manganate, which is applied in structural parts, battery electrodes, electrical components, etc., achieves the effects of stable high-temperature cycle performance, simple and easy preparation methods, and cheap and easy-to-obtain raw materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Proceed as follows:

[0026] (1) KMnO 4 Dissolve in deionized water, add appropriate amount of hydrochloric acid, and make KMnO 4 A solution with a concentration of 0.01mol / L and a hydrochloric acid concentration of 0.5mol / L;

[0027] (2) After the above mixed solution is stirred evenly, it is pumped into the hydrothermal reaction kettle and reacted at 120 ℃ to form the precursor β-MnO 2 ;

[0028] (3) After the precursor is filtered, washed and dried, it is evenly mixed with lithium compound and aluminum nitrate in a molar ratio of Li:Al:Mn=1:0.1:1.9, and the drying is carried out at 80°C;

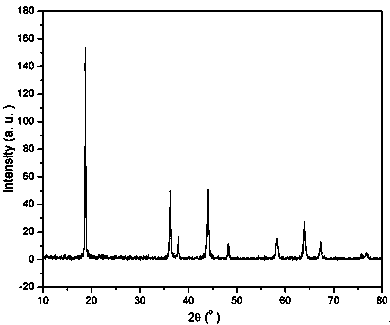

[0029] (4) The homogeneous mixture of the precursor and the lithium compound is fired in a tube furnace at a high temperature of 700 ° C for 10 h, and LiAl is obtained after cooling down to room temperature 0.1 mn 1.9 o 4 Material.

[0030] The mixed solution added to the reactor in step (2) accounts for 50% of the total volume of the reactor, and the reaction time is 14 ho...

Embodiment 2

[0035] Proceed as follows:

[0036] (1) KMnO 4 Dissolve in deionized water, add appropriate amount of hydrochloric acid, and make KMnO 4 A solution with a concentration of 0.015mol / L and a hydrochloric acid concentration of 0.7mol / L;

[0037] (2) After the above mixed solution is stirred evenly, it is pumped into the hydrothermal reaction kettle, and reacted at 150 ℃ to form the precursor β-MnO 2 ;

[0038] (3) After the precursor is filtered, washed and dried, it is evenly mixed with lithium compound and aluminum nitrate in a molar ratio of Li:Al:Mn=1:0.1:1.9, and the drying is carried out at 100°C;

[0039] (4) Burn the homogeneous mixture of the precursor and the lithium compound in a tube furnace at a high temperature of 750°C for 15 hours, and obtain LiAl after cooling down to room temperature. 0.1 mn 1.9 o 4 Material.

[0040] The mixed solution added to the reactor in step (2) accounts for 70% of the total volume of the reactor, and the reaction time is 17 hours....

Embodiment 3

[0045] Proceed as follows:

[0046] (1) KMnO 4 Dissolve in deionized water, add appropriate amount of hydrochloric acid, and make KMnO 4 A solution with a concentration of 0.02mol / L and a hydrochloric acid concentration of 0.8mol / L;

[0047] (2) After the above mixed solution is stirred evenly, it is pumped into the hydrothermal reaction kettle and reacted at 170 ℃ to form the precursor β-MnO 2 ;

[0048] (3) After the precursor is filtered, washed and dried, it is evenly mixed with lithium compound and aluminum nitrate in a molar ratio of Li:Al:Mn=1:0.1:1.9, and the drying is carried out at 120°C;

[0049] (4) The homogeneous mixture of the precursor and the lithium compound is fired in a tube furnace at a high temperature of 800 ° C for 20 hours to obtain LiAl 0.1 mn 1.9 o 4 Material.

[0050] The mixed solution added to the reactor in step (2) accounts for 80% of the total volume of the reactor, and the reaction time is 20 hours.

[0051] The filtration and washing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com