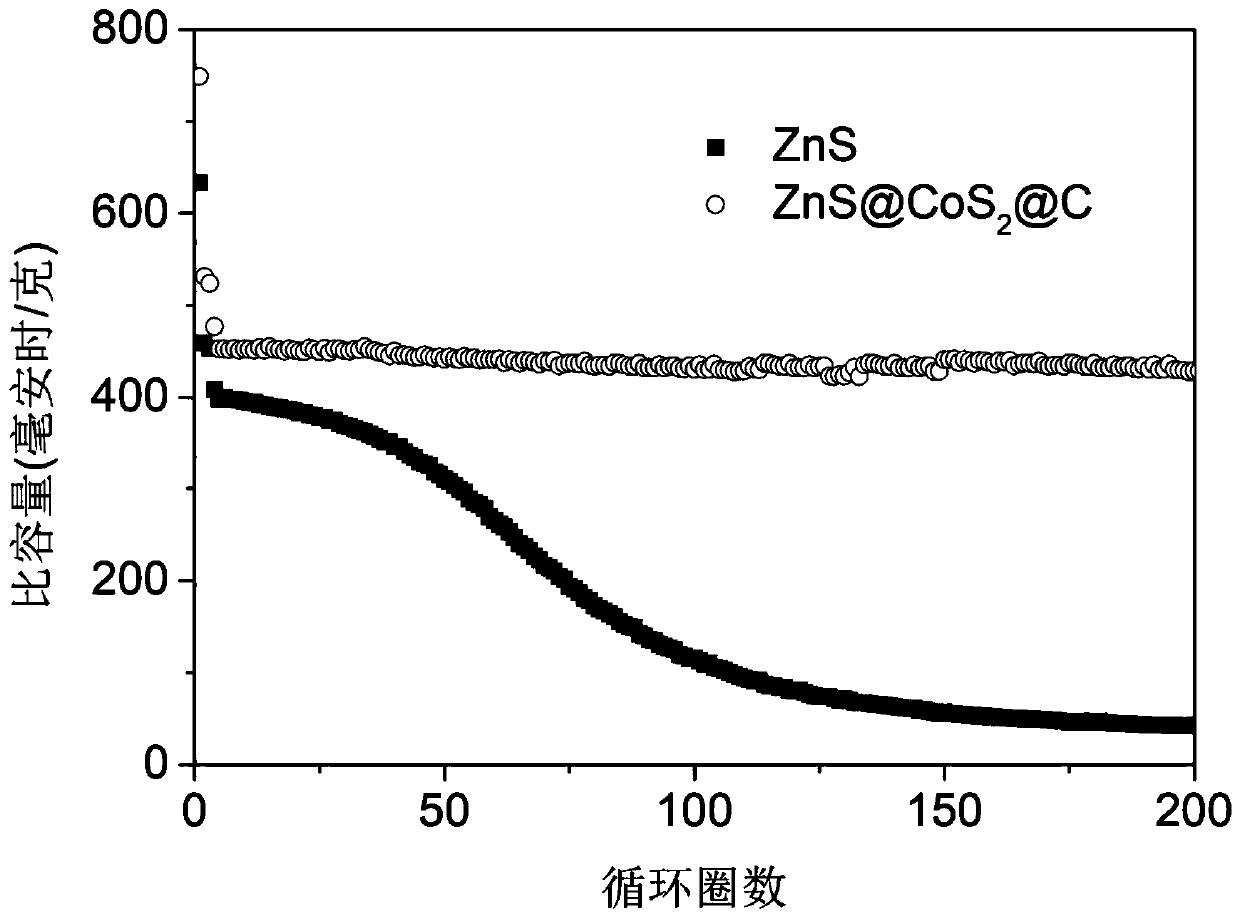

Preparation method of sodium ion battery negative electrode material of zinc-cobalt bimetal sulfide

A sodium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of poor cycle life and stability, improve specific capacity and stability, increase capacity and service life, increase The effect of specific capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The first step: the preparation of ZnO nanospheres:

[0033] Dissolve 0.88g of zinc acetate and 0.62g of triethanolamine in 40mL and 200mL of water, respectively, then magnetically stir for 15min, and then transfer ultrasound for 30min to obtain a milk-like suspension. Then the solution was left to stand for 12h. After standing still, samples were collected by centrifugation, washed three times with water and ethanol, and dried in an oven at 60° C. to obtain ZnO nanospheres.

[0034] Step 2: Synthesis of ZnO@Co-MOF material

[0035] Dissolve 0.04g of ZnO nanospheres prepared in step (1) in 10mL of ethanol, ultrasonically treat for 10min, then add 0.293g of cobalt nitrate hexahydrate to the solution, continue to sonicate for 10min, and mark it as A solution. Dissolve imidazole in 10mL ethanol, mark it as solution B, quickly pour solution B into solution A, keep stirring for 2 hours, collect samples by centrifugation, wash with methanol three times, and dry them in an o...

Embodiment 2

[0042] The first step: the preparation of ZnO nanospheres:

[0043] Zinc acetate and triethanolamine were dissolved in 40mL and 200mL of water, respectively, then magnetically stirred for 15min, and then transferred to ultrasound for 30min to obtain a milky suspension. Then the solution was left to stand for 12h. After standing still, samples were collected by centrifugation, washed three times with water and ethanol, and dried in an oven at 60° C. to obtain ZnO nanospheres.

[0044] Step 2: Synthesis of ZnO@Co-MOF material

[0045] Dissolve the ZnO nanospheres prepared in step (1) in ethanol, ultrasonically treat for 10min, then add cobalt nitrate hexahydrate to the solution, continue ultrasonication for 10min, mark it as A solution, dissolve dimethylimidazole in ethanol, Labeled as solution B, quickly pour solution B into solution A, keep stirring for 2 hours, separate by centrifuge, collect samples, wash with methanol three times, and dry in an oven at 60°C to obtain ZnO@...

Embodiment 3

[0049] The first step: the preparation of ZnO nanospheres:

[0050] Zinc acetate and triethanolamine were dissolved in 40mL and 200mL of water, respectively, then magnetically stirred for 15min, and then transferred to ultrasound for 30min to obtain a milky suspension. Then the solution was left to stand for 12h. After standing still, samples were collected by centrifugation, washed three times with water and ethanol, and dried in an oven at 60° C. to obtain ZnO nanospheres.

[0051] Step 2: Synthesis of ZnO@Co-MOF material

[0052] Dissolve the ZnO nanospheres prepared in step (1) in ethanol, ultrasonically treat for 10min, then add cobalt nitrate hexahydrate to the solution, continue ultrasonication for 10min, mark it as A solution, dissolve dimethylimidazole in ethanol, Labeled as solution B, quickly pour solution B into solution A, keep stirring for 2 hours, separate by centrifuge, collect samples, wash with methanol three times, and dry in an oven at 60°C to obtain ZnO@...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com