Ultrafine high-bending resistance alloy powder used for diamond tool and preparation method for ultrafine high-bending resistance alloy powder

A technology for diamond tools and alloy powders is applied in the field of ultra-fine and high-flexural strength alloy powders for diamond tools and their preparation. High sintering activity and improved holding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The present invention also relates to a preparation method of ultrafine high bending strength alloy powder for diamond tools, the steps of which are as follows:

[0033] 1) Prepare the metal raw materials, and prepare the metal components according to the weight percentage as follows: Cu: 5-85%, Ni: 1-25%, Sn: 1-20%, Si: 0-8%; Al: 1-15% ;Cr: 5~15%; B: 0.1~5%; V: 0.1~6%; Nb: 0.1~5%; Zr: 0.1~5%; La: 0.1~10%; Fe balance;

[0034] 2) Preparation by using the prepared metal raw materials, followed by steps of ① smelting, ② water atomization, ③ dehydration by pressure filtration, ④ vacuum drying and ⑤ reduction, to obtain the ultrafine high flexural strength water atomized alloy powder of the present invention. Each sub-step in step 2) is described in detail below.

[0035]①In the smelting step, the smelting is smelted by an intermediate frequency induction furnace. The total amount of material fed to each furnace does not exceed 220kg, and the power is controlled between 60...

specific Embodiment 1

[0043] The alloy powder produced by the invention is formulated according to the composition design, the raw materials are smelted at high temperature, atomized with high-pressure water, vacuum dried and hydrogen deoxidized, and the product powder is obtained after sieving. The product powder is hot-pressed into a standard flexural strength sample block, and a three-point flexural strength test is performed with a flexural strength testing machine.

[0044] The metal raw materials and weights used are as follows:

[0045] raw material

Fe

Ni

Cu

Si

sn

Cr

AL

La

V

Nb

Zr

B

Gross weight, kg

weight

119.3

8.8

44.0

6.6

8.8

11.0

15.4

0.25

1.65

1.32

0.24

2.64

220

[0046] A medium-frequency induction smelting furnace with a furnace capacity of 250kg for industrial production is used. The furnace lining is made of magnesia. Fe, Ni, Si, Sn, and Cr are first put in...

specific Embodiment 2

[0050] Compared with Example 1, Example 2 adjusted the raw material addition.

[0051] raw material

Fe

Ni

Cu

Si

sn

Cr

AL

La

V

Nb

Zr

B

Gross weight, kg

weight

77.2

22.0

66.0

6.6

4.4

22.0

11.0

0.5

2.5

2.64

0.24

4.92

220

[0052] The input sequence of raw materials and the smelting method are the same as in Example 1. Adjust the atomization pressure to 135MPa. The atomized water-powder mixture is filtered through compressed air. Put the dehydrated wet powder into a desiccator for vacuum drying. Put the dried powder into the reduction furnace, and reduce it with hydrogen at 550°C for 30 minutes. The reduced powder is sieved with a 500-mesh sieve to obtain the final product powder.

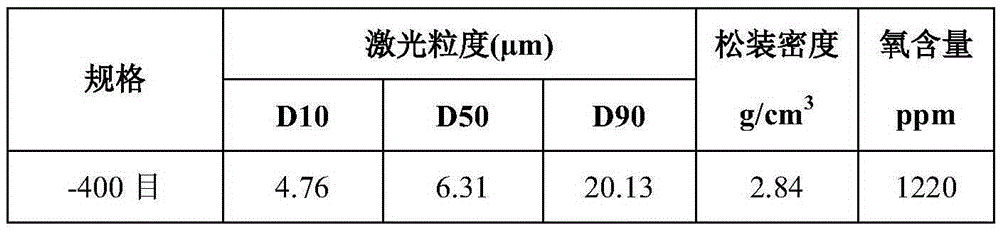

[0053] The final product powder test results are as follows:

[0054]

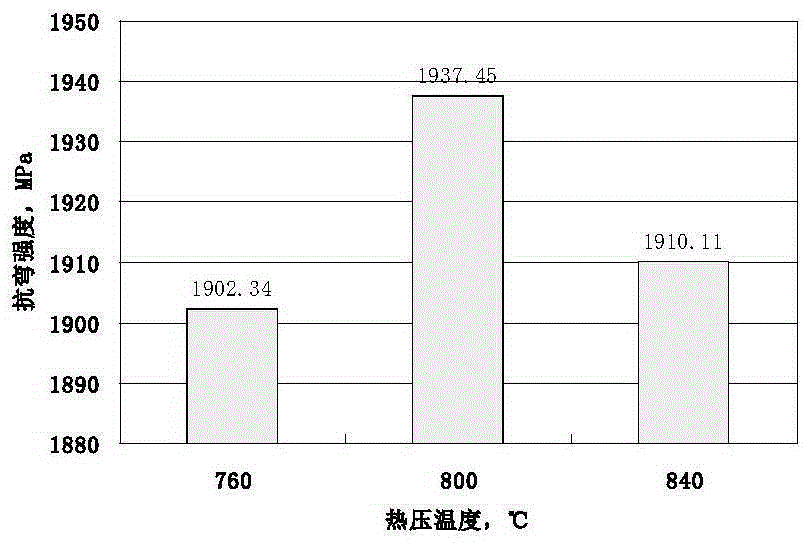

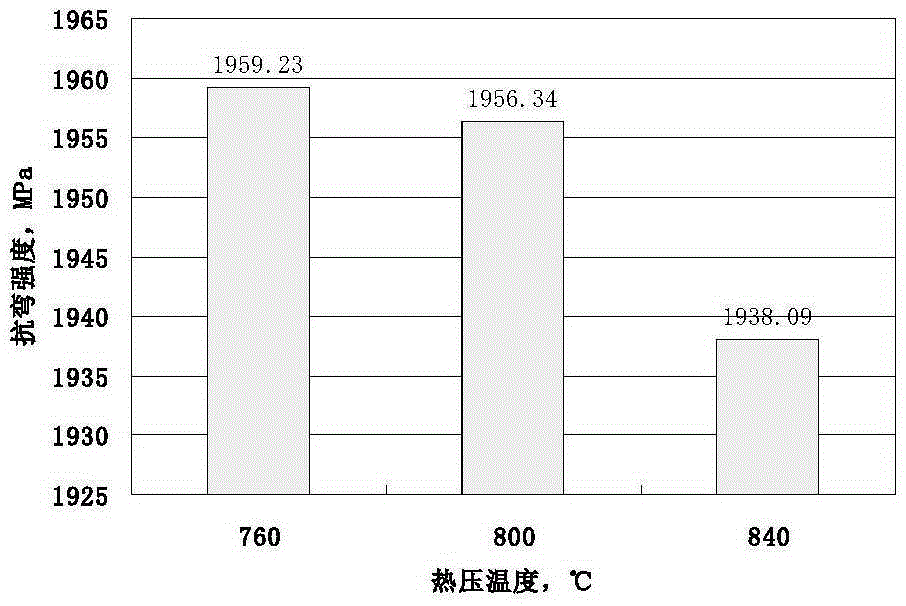

[0055] The bending strength test results can be found in figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com