Nickel silver alloy and processing technique

A processing technology, the technology of zinc white copper, applied in the field of coinage, can solve the problems of poor corrosion resistance, achieve excellent processing performance and corrosion resistance, avoid component segregation, and improve the effect of strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

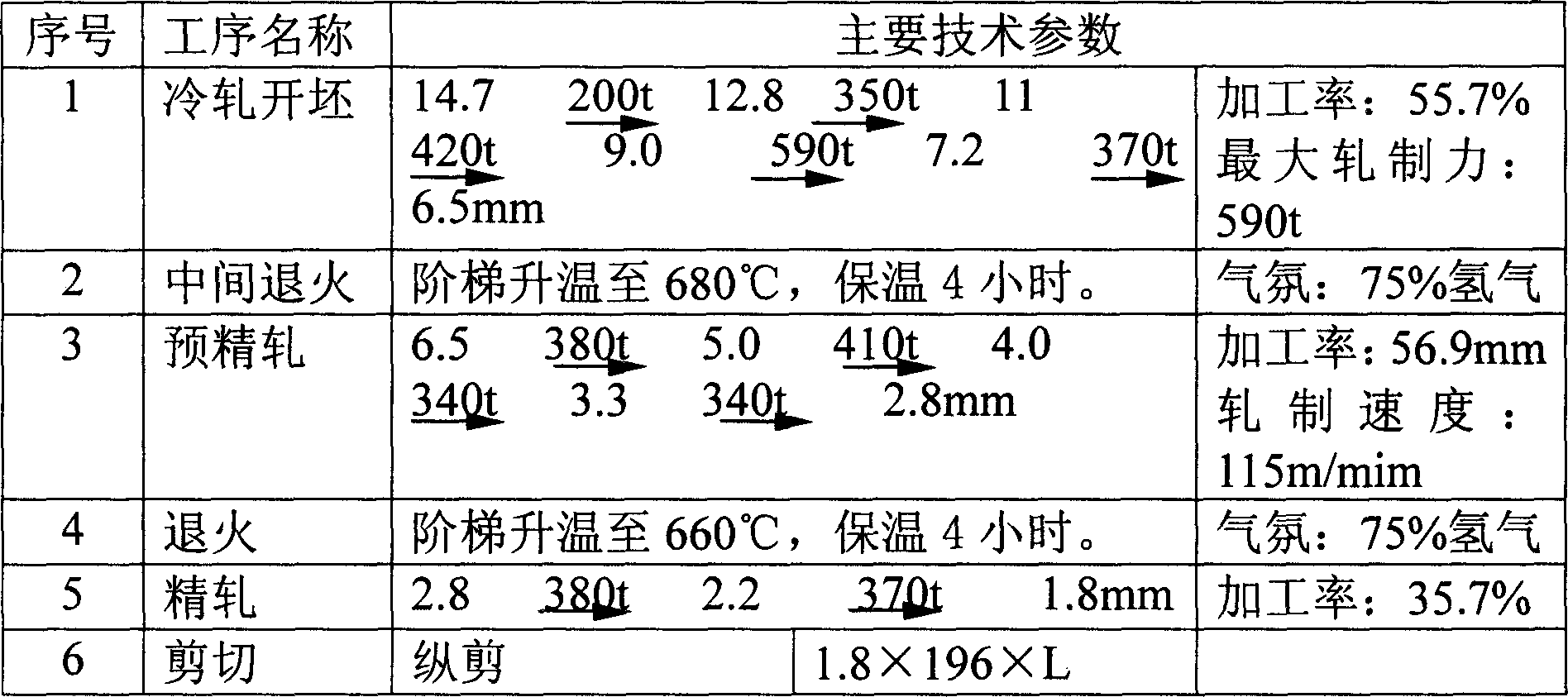

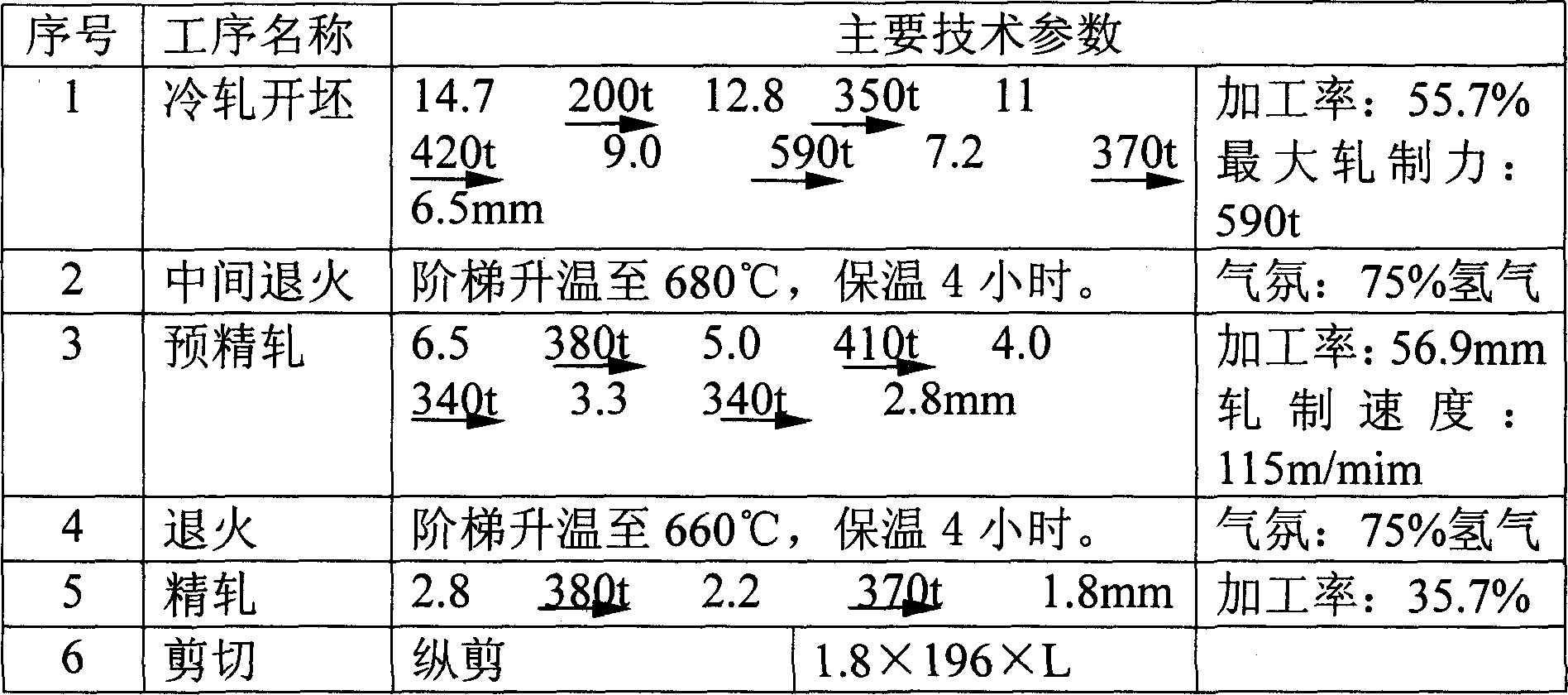

Examples

Embodiment 1

[0047] Composition of the present invention (by weight percentage):

[0048] Cu67%, Ni14%, Zn19%.

[0049] The processing technique of zinc-nickel-nickel alloy of the present invention:

[0050] 1. Alloy smelting process

[0051] (1), raw materials: electrolytic copper, electrolytic nickel, zinc ingot, Cu-Mg

[0052] (2), technical conditions and parameters:

[0053] Billet specification: 420×16×Lmm

[0054] Melting temperature: 1300~1320℃

[0055] Deoxidizer: Cu-Mg, Cu-Mn master alloy

[0056] Covering agent: carbonized charcoal

[0057] (3) The order of feeding: electrolytic copper → electrolytic nickel → zinc ingot → Cu-Mn alloy → slag removal → sampling analysis → temperature measurement → adding charcoal and blowing out the furnace.

[0058] 2. Horizontal continuous casting

[0059] (1), drawing temperature: 1230 ℃

[0060] (2), casting procedure

[0061] Pull 15.00mm 1s

[0062] Stop 1 1s

[0063] Reverse thrust 1 1mm 0.1s

[0064] Stop 2 2s

[0065] Revers...

Embodiment 2

[0073] The composition (by weight percentage) of optimal value of the present invention:

[0074] Cu68%, Ni15%, Zn17%.

[0075] The processing technique of zinc-nickel-nickel alloy of the present invention:

[0076] 1. Alloy smelting process

[0077] (1), raw materials: electrolytic copper, electrolytic nickel, zinc ingot, Cu-Mg

[0078] (2), technical conditions and parameters:

[0079] Billet specification: 420×16×Lmm

[0080] Melting temperature: 1320°C

[0081] Deoxidizer: Cu-Mg, Cu-Mn master alloy

[0082] Covering agent: carbonized charcoal

[0083] (3) The order of feeding: electrolytic copper → electrolytic nickel → zinc ingot → Cu-Mn alloy → slag removal → sampling analysis → temperature measurement → adding charcoal and blowing out the furnace.

[0084] 2. Horizontal continuous casting

[0085] (1), drawing temperature: 1250 ℃

[0086] (2), casting procedure

[0087]Pull 15.00mm 1s

[0088] Stop 1 1s

[0089] Reverse thrust 1 1mm 0.1s

[0090] Stop 2 2s ...

Embodiment 3

[0098] Composition of the present invention (by weight percentage):

[0099] Cu69%, Ni16%, Zn15%.

[0100] Its processing technology is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com