Patents

Literature

67 results about "Nickel silver" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nickel silver, Maillechort, German silver, Argentan, new silver, nickel brass, albata, alpacca, is a copper alloy with nickel and often zinc. The usual formulation is 60% copper, 20% nickel and 20% zinc. Nickel silver is named due to its silvery appearance, but it contains no elemental silver unless plated. The name "German silver" refers to its development by 19th-century German metalworkers from the Chinese alloy known as paktong (白銅) (cupronickel). All modern, commercially important nickel silvers (such as those standardized under ASTM B122) contain significant amounts of zinc, and are sometimes considered a subset of brass.

Lead free reduced ricochet limited penetration projectile

A frangible projectile with a specific gravity similar to a lead projectile. The projectile comprises 34-94%, by weight, binder. The binder comprises poly ether block amide resin. The projectile further comprises 6-66%, by weight, ballast. The ballast comprises at least one member selected from a group consisting of tungsten, tungsten carbide, molybdenum, tantalum, ferro-tungsten, copper, bismuth, iron, steel, brass, aluminum bronze, beryllium copper, tin, aluminum, titanium, zinc, nickel silver alloy, cupronickel and nickel. The projectile can be prepared with a particularly preferred specific gravity of 5-14 and more preferably 11-11.5.

Owner:ACCUTEC USA

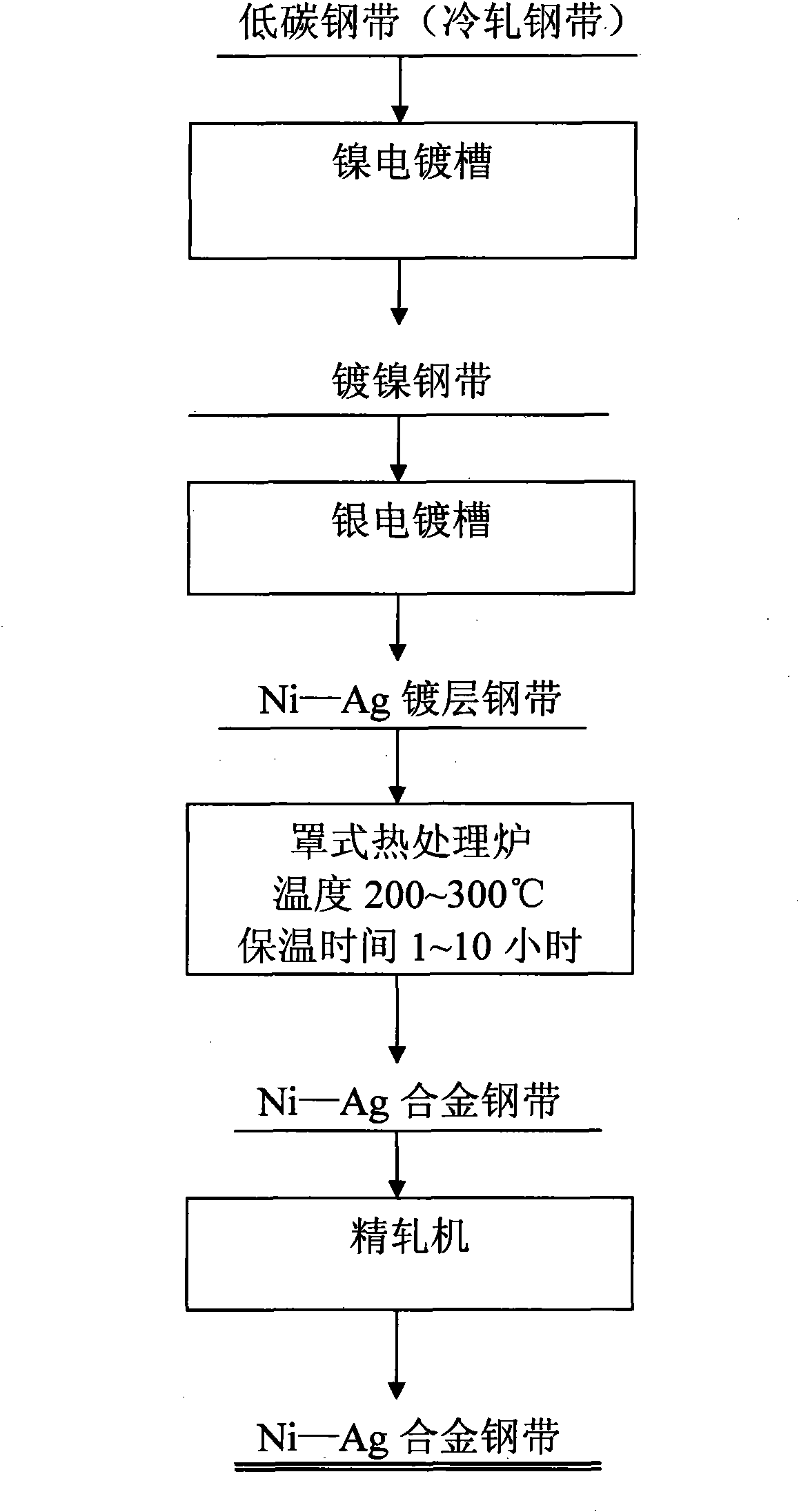

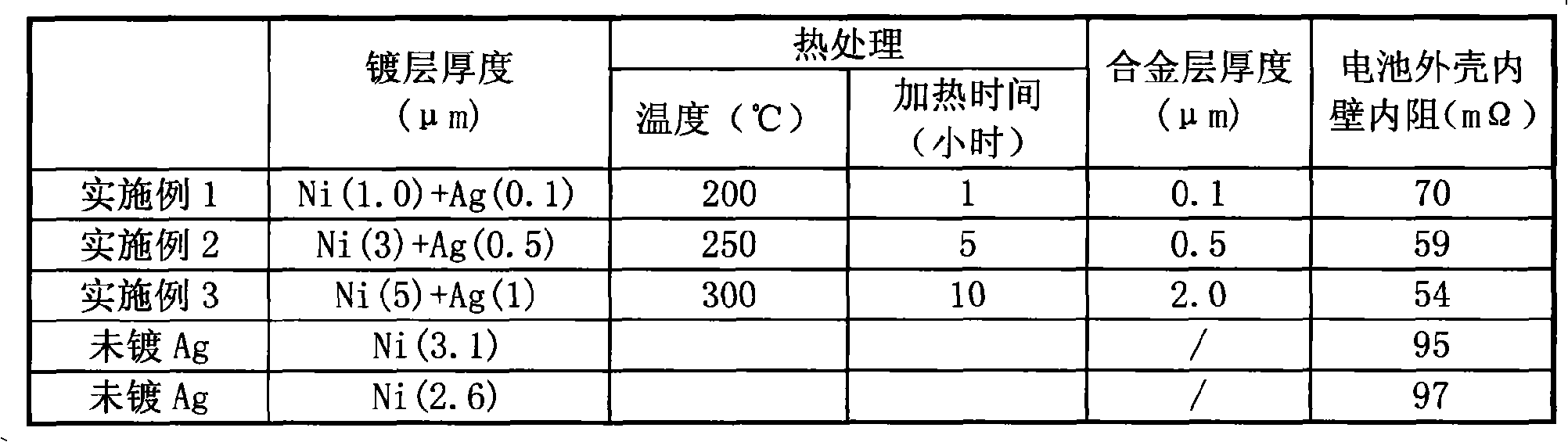

Preparation method of nickel-silver alloy steel strip for battery case

InactiveCN101597780ANot easy to produceImprove corrosion resistanceCell component detailsSilver plateThermal treatment

The invention discloses a preparation method of nickel-silver alloy steel strip for battery case. The method uses mild-carbon steel strip as substrate through chemical degreasing, electrolytic degreasing and acid cleaning, characterized by the following steps: A. putting the mild-carbon steel strip in nickel plating bath, plating for 1 to 5min to form nickel coating layer with the sediment thickness of single side or double-side of 1 to 5 microns; B. putting the steel strip plated with nickel layer in the silver plating bath for 0.5 to 5min, controlling the silver coating layer settled on the nickel coating layer to be 0.1 to 1.0 microns; C. thermal treatment, putting the steel strip of nickel-silver coating layer in a bell type furnace to process thermal treatment at 200 to 300 DEG C, keeping temperature for 1 to 10 hours, forming a nickel-silver alloy steel strip with thickness of 0.1 to 2.0 microns; and D. finish rolling, conveying the nickel-silver alloy steel strip with timeliness during the thermal treatment to finishing mill to roll. The invention is mainly used to prepare nickel-silver alloy steel strip for battery case.

Owner:HUNAN TOYO LEED MATERIAL SCI & TECH CO LTD

Nickel silver alloy and processing technique

This invention relates to a zincum-white copper alloy and its processing technique. It comprises of 67~69wt% of Cu, 14~16wt% of Ni and 15~19wt% of zincum. Due to the creativity in weight percentage of the Cu-Ni-Zn ternary alloy in this invention, the alloy shows a considerably silvery color, an outstanding strength, wear resistance, corrosion resistance and discoloration resisting properties. This invention stressed a raw materials cost as low as possible, meanwhile assures excellent founding properties, corrosion resisting properties and coin processing properties.

Owner:CHINA BANKNOTE PRINTING & MINTING

Covering-type copper-nickel-silver composite powder and preparation method thereof

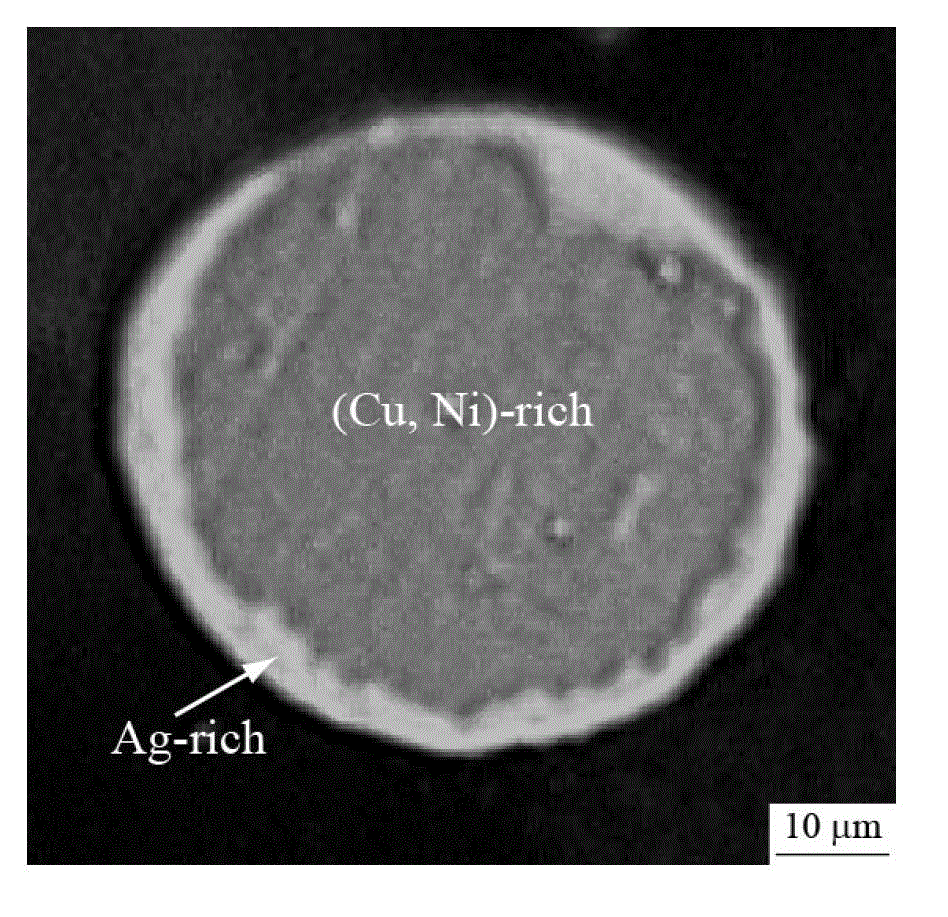

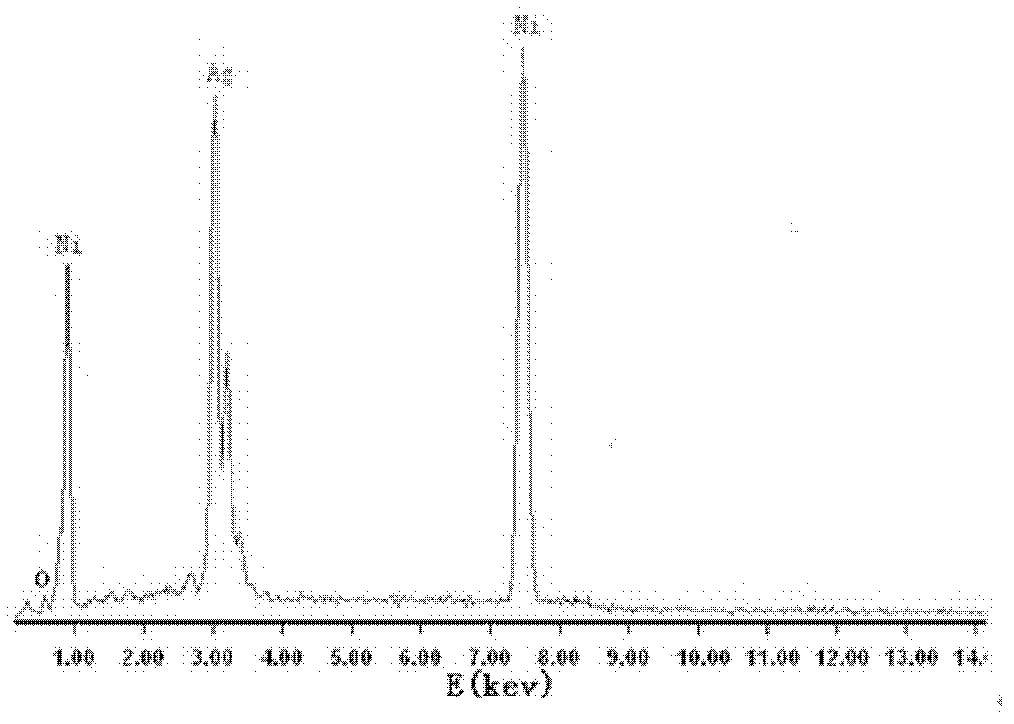

The invention discloses covering-type copper-nickel-silver composite powder and a preparation method thereof, relating to composite powder. The covering-type copper-nickel-silver composite powder comprises an inner core and a shell, wherein the inner core is a copper-nickel alloy core; the shell is a sliver alloy shell; the covering-type copper-nickel-silver composite powder comprises the following components in percentage by mass: 10-40% of Cu, 40-50% of Ni and the balance of Ag. Copper, nickel and silver are molten in a smelting device in a vacuum induction furnace, molten alloy liquid is poured into a liquid receiving hopper, and inert gas is injected at the moment when liquid flows into an atomizing chamber to obtain the covering-type copper-nickel-silver composite powder. According to an atomization method powder preparation technology, the covering-type copper-nickel-silver composite powder is prepared in one time without any chemical compound technology, so that the prepared covering-type copper-nickel-silver composite powder has the advantages of simple technology, high efficiency, small pollution, high powder product quality, and favorable interface bonding, can become a replacer of silver powder in the conductive filler field, and dual requirements of mechanicalness and functionality can be satisfied.

Owner:XIAMEN UNIV

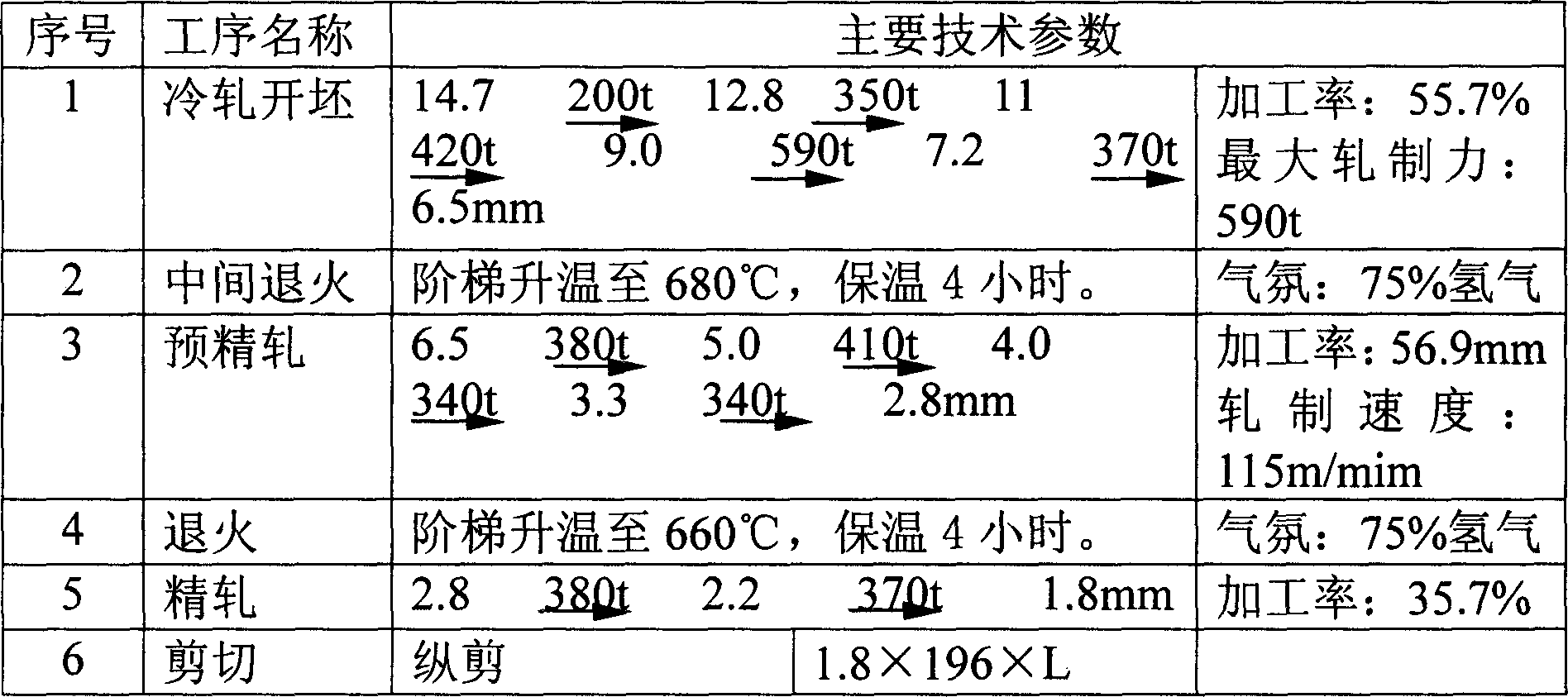

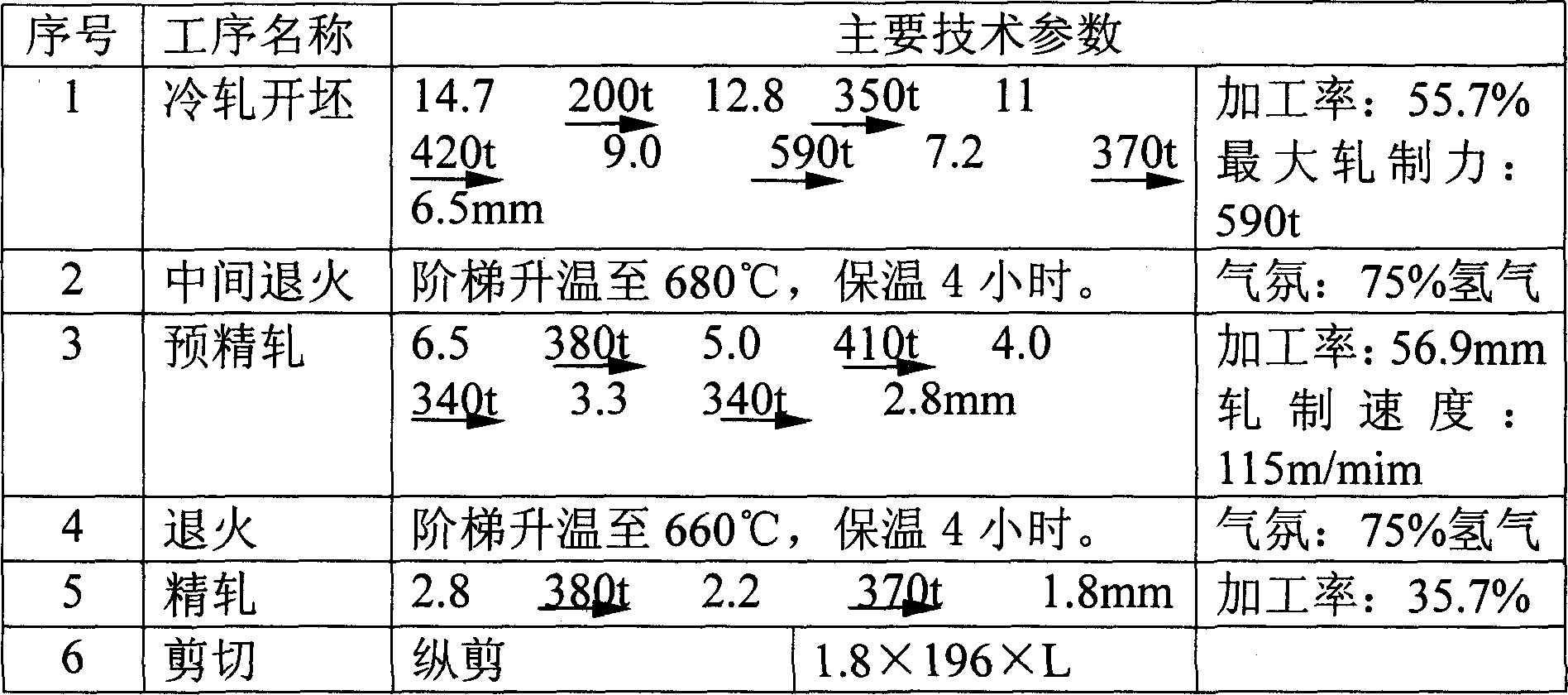

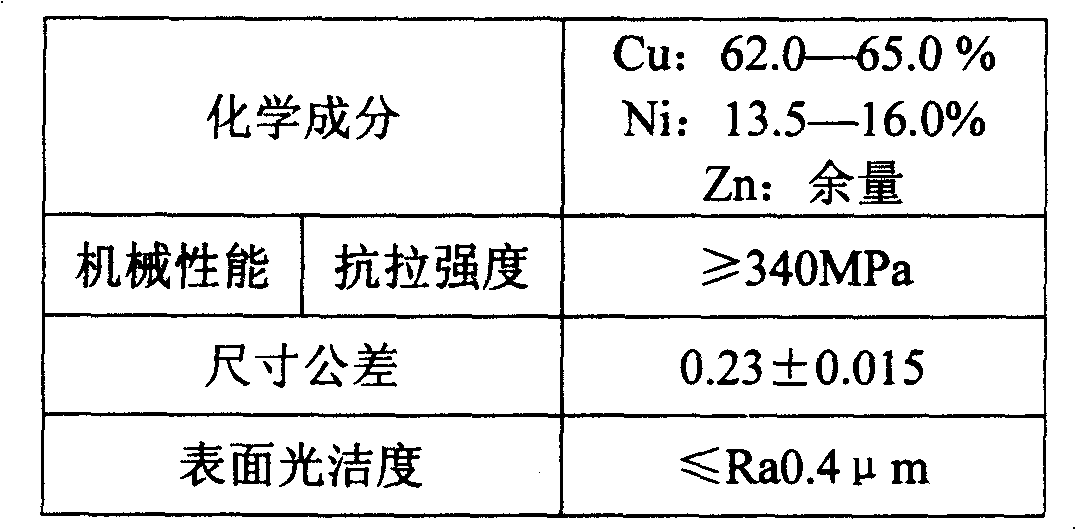

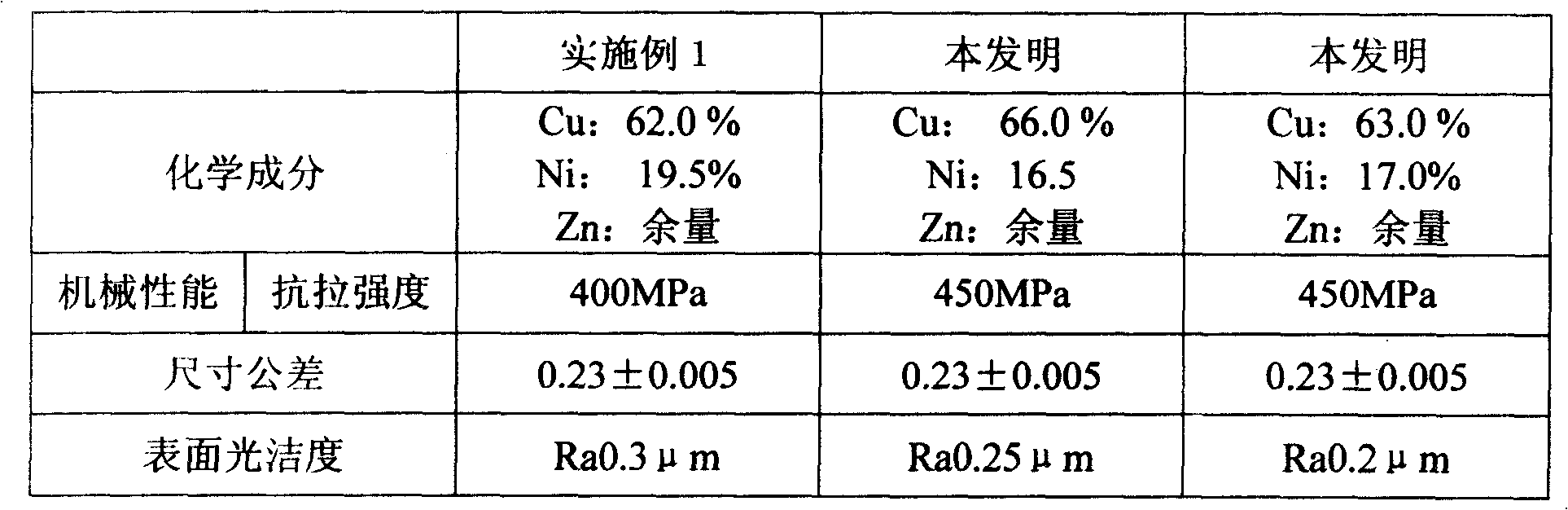

Nickel silver band for piezoelectric crystal oscillator housing and method for producing same

ActiveCN1690236AOscillations generatorsPiezoelectric/electrostrictive/magnetostrictive devicesSurface finishManufacturing technology

A packfong belt applying to the shell of piezoelectric crystal oscillator, the material of the copper alloy is prepared by adding nickel and zinc element, and the main chemical constituent is as following: Cu: 62.0 to 66.0 percent; Ni: 16.5 to 19.5 percent; Zn: residual. The workflow is: material checking and accepting - batching - melting - sampling and analyzing (adjusting constituent) - rolling in holding furnace - sampling and analyzing (adjusting constituent) - horizontal continuous casting - batching on - milling - cool cogging rolling - end shearing - intermediate annealing - cold rolling - intermediate annealing - fine rolling - end item annealing - cutting - end item quality inspection - packaging and warehouse-in. The invention settles many technical problems, such as the low tensile strength, the high dimensional tolerance and the poor surface finish quality of the present packfong belt, and it also improves the the shielding property and corrosion resistance.

Owner:中铜(上海)铜业有限公司

Preparation method for core-shell structural nickel-silver bimetallic powder

InactiveCN102672168ANarrow particle size distributionGood dispersionCoatingsHydrazine compoundVolumetric Mass Density

The invention relates to the technical field of the preparation of metal powder materials and particularly discloses a preparation method for core-shell structural nickel-silver bimetallic powder. The preparation method comprises the following steps of: adding nickel powder and a dispersing agent in an ethanol-water mixed solvent, and stirring to obtain a nickel powder dispersing solution; preparing hydrazine hydrate solution with the hydrazine hydrate concentration of 2.5 mol / L, and adjusting the pH value of the hydrazine hydrate solution to more than 10 to obtain a reducing agent solution; mixing the nickel powder dispersing solution with the reducing agent solution to obtain a reaction solution A; dropwise adding an ammonia-silver solution in the reaction solution A and reacting for 70-100 minutes to obtain turbid liquid; performing centrifugal separation, washing and vacuum-drying the obtained solid to obtain the core-shell structural nickel-silver bimetallic powder. The preparation method provided by the invention has simple process; the obtained core-shell structural nickel-silver bimetallic powder has the advantages of controllable thickness of a silver coating layer, narrow distribution of grain diameter, good dispersing property and high vibrating density.

Owner:HENAN UNIV OF SCI & TECH

Method of preparing nickel-silver nuclear shell structure nano-particles

The invention relates to the field of preparation of functional nanometer materials and materials, in particular to a method of preparing nickel-silver nuclear shell structure nano-particles. The method specifically comprises the following steps of: dissolving silver nitrate into water as plating solution; clearly cleaning nanometer nickel powder which is sensitized by sub-tin ions, adding plating solution, stirring and dispersing, after a certain time, titrating clear liquid through diluted hydrochloric acid to observe whether white precipitate is generated, and checking existence of Ag<+> so as to judge whether reaction is complete; after reacting completely, separating a product through a magnet, washing by deionized water and absolute ethyl alcohol, and drying in vacuum at 40 DEG C for 12 hours. According to the invention, the nickel-silver nuclear shell structure nano-particles can be synthesized on the basis of the prepared nanometer nickel particles, the operating method is simple and practicable, moderate in reaction conditions and simple in required devices, the prepared nickel-silver nuclear shell structure nano-particles has the advantages of strong binding force, good dispersibility and compact coating, and furthermore, the thickness of a silver shell can be controlled through changing additive amount of the silver nitrate.

Owner:JIANGSU UNIV

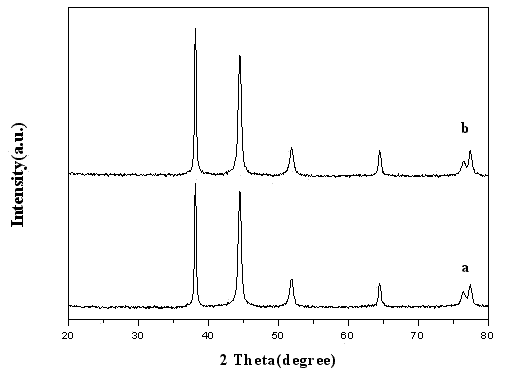

Silver-white copper alloy and process for producing the same

To provide a silver-white copper alloy which represents a silver-white color equivalent to that of nickel silver and is excellent in hot workability and the like. The silver-white copper alloy includes 47.5 to 50.5 mass % of Cu, 7.8 to 9.8 mass % of Ni, 4.7 to 6.3 mass % of Mn, and the remainder including Zn, and the silver-white copper alloy has an alloy composition satisfying relationships of f1=[Cu]+1.4×[Ni]+0.3×[Mn]=62.0 to 64.0, f2=[Mn] / [Ni]=0.49 to 0.68, and f3=[Ni]+[Mn]=13.0 to 15.5 among a content [Cu] mass % of Cu, a content [Ni] mass % of Ni, and a content [Mn] mass % of Mn, and has a metal structure in which β phases at an area ratio of 2 to 17% are dispersed in an α-phase matrix. The copper alloy is provided as a hot processing material or continuous casting material formed by performing one or more heat treatments and cold processes on a hot processing raw material formed by performing a hot process on an ingot or a casting raw material obtained by continuous casting.

Owner:MITSUBISHI SHINDOH CO LTD

Nickel silver platinum rhodium multilayer composite plating process

The composite multilayer Ni, Ag, Pt and Rh electroplating process includes successive Ag pre-electroplating step, Ni-electroplating step, Ag-electroplating step and Pt and Rh electroplating step, with special requirement in electrolyte composition and pH value, electroplating temperature and time, electrode current density and other technological parameters. The said electroplating process has no problem of color change in Ag plated surface, and the coating is bright, smooth, beautiful, fast and without color change.

Owner:刘广斯

Nickel plating method for electroplating bright nickel silver

The invention relates to the technical field of surface treatment, and in particular relates to a nickel plating method for electroplating bright nickel silver. The method comprises the following steps: polishing; deoiling; microetching; electroplating bright nickel; washing with sulfuric acid; pre-plating silver; plating silver; washing with water; and drying, wherein the roughness of the polished surface of a raw material is not beyond 4 microns; 10% AD-482 deoiling agent is used; a microetching solution per liter comprises the following components: 60g of sodium persulfate, 20ml of sulfuric acid, and the balance water; a nickel electroplating solution per liter comprises the following components: 75-85g of Ni, 12-17g of Cl<->, 45-55g of boric acid, 180-220ml of bright nickel brightening agent, 20-35ml of wetting agent, and the balance water; a silver pre-plating solution per liter comprises the following components: 0.5-1.0g of Ag, 90-130g of editpotassium cyanide, and the balance water; a silver plating solution per liter comprises the following components: 20-40g of Ag, 110-150g of editpotassium cyanide, 90-110g of potassium carbonate, 40-60ml of NI-6160-B brightening agent, 15-25ml of NI-6160-C additive, and the balance water. The raw material processed by the method is high in surface uniformity; a plating layer cannot fall off; the abrasion resistance is high; the applicable scope is wide; and the light reflectivity is increased.

Owner:东莞市诚志电子有限公司

Preparation method for core-shell structural nickel-silver bimetallic powder

The invention relates to the technical field of the preparation of metal powder materials and particularly discloses a preparation method for core-shell structural nickel-silver bimetallic powder. The preparation method comprises the following steps of: adding nickel powder and a dispersing agent in an ethanol-water mixed solvent, and stirring to obtain a nickel powder dispersing solution; preparing hydrazine hydrate solution with the hydrazine hydrate concentration of 2.5 mol / L, and adjusting the pH value of the hydrazine hydrate solution to more than 10 to obtain a reducing agent solution; mixing the nickel powder dispersing solution with the reducing agent solution to obtain a reaction solution A; dropwise adding an ammonia-silver solution in the reaction solution A and reacting for 70-100 minutes to obtain turbid liquid; performing centrifugal separation, washing and vacuum-drying the obtained solid to obtain the core-shell structural nickel-silver bimetallic powder. The preparation method provided by the invention has simple process; the obtained core-shell structural nickel-silver bimetallic powder has the advantages of controllable thickness of a silver coating layer, narrow distribution of grain diameter, good dispersing property and high vibrating density.

Owner:HENAN UNIV OF SCI & TECH

Polyimide film externally coated with metal conductive layer and preparation method thereof

InactiveCN101630540ANot easy to damage and failStrong metallic lusterConductive layers on insulating-supportsMagnetic/electric field screeningElectromagnetic shieldingGraphite

The invention relates to a polyimide film externally coated with a metal conductive layer and a preparation method thereof. The polyimide film is provided with a polyimide insulating layer and a metal conductive layer and is characterized in that a middle bonding layer playing a role of bidirectional bonding is arranged between the polyimide insulating layer and the metal conductive layer. The middle bonding layer comprises the following components in percentage by weight: 35-50 percent of polyimide as a main component, 3-12.5 percent of graphite, 3-12.5 percent of conductive black carbon, 0.6-6 percent of silane coupling agent, 2-10 percent of nickel-silver curing agent, 4-16 percent of conductive paint conductivity promoting agent and 2-10 percent of leveling agent. The preparation method comprises the steps of coating, drying, curing for molding, polishing, and the like. The polyimide film externally coated with the metal conductive layer can be widely applied to the high-tech field of protective devices with special purposes, and the like of electronics, electrical appliances, electromagnetic shielding, electromagnetic radiation and power transmission and transformation projects.

Owner:陈贤斌

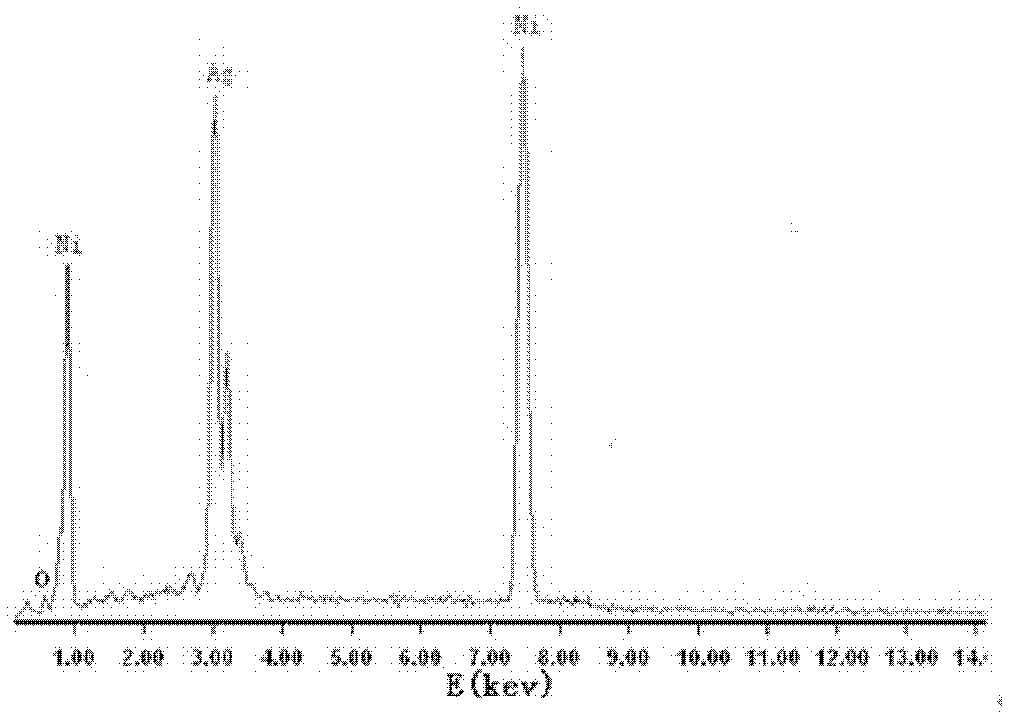

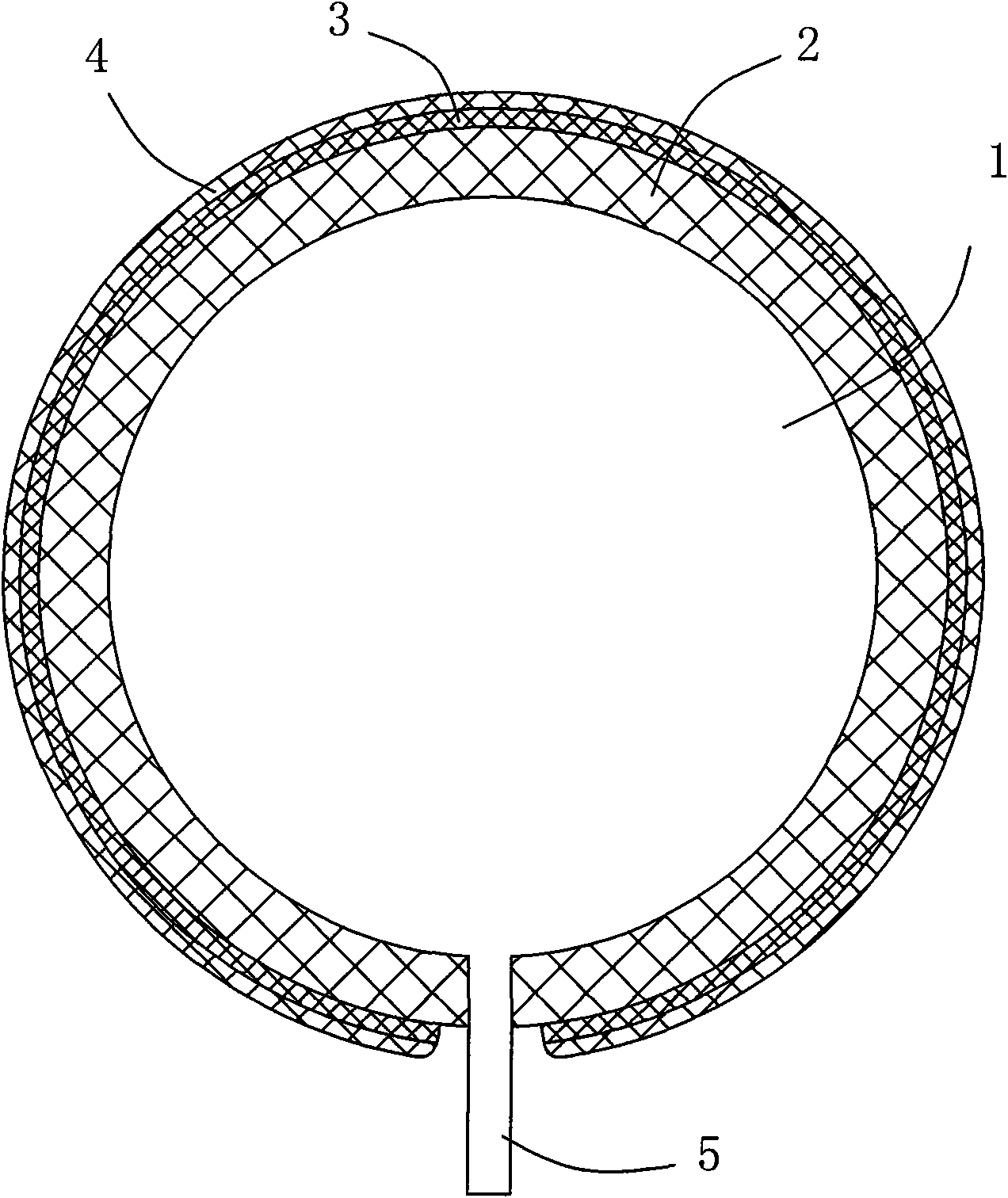

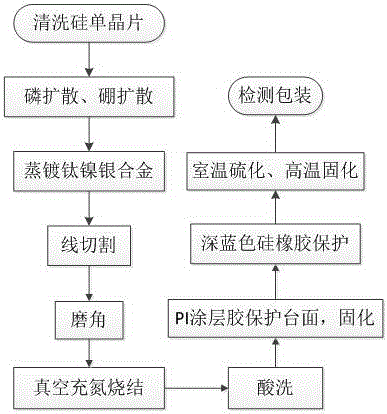

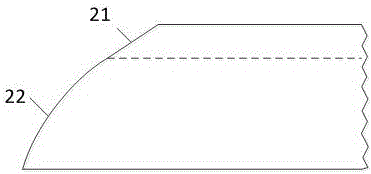

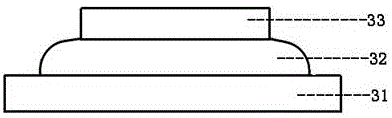

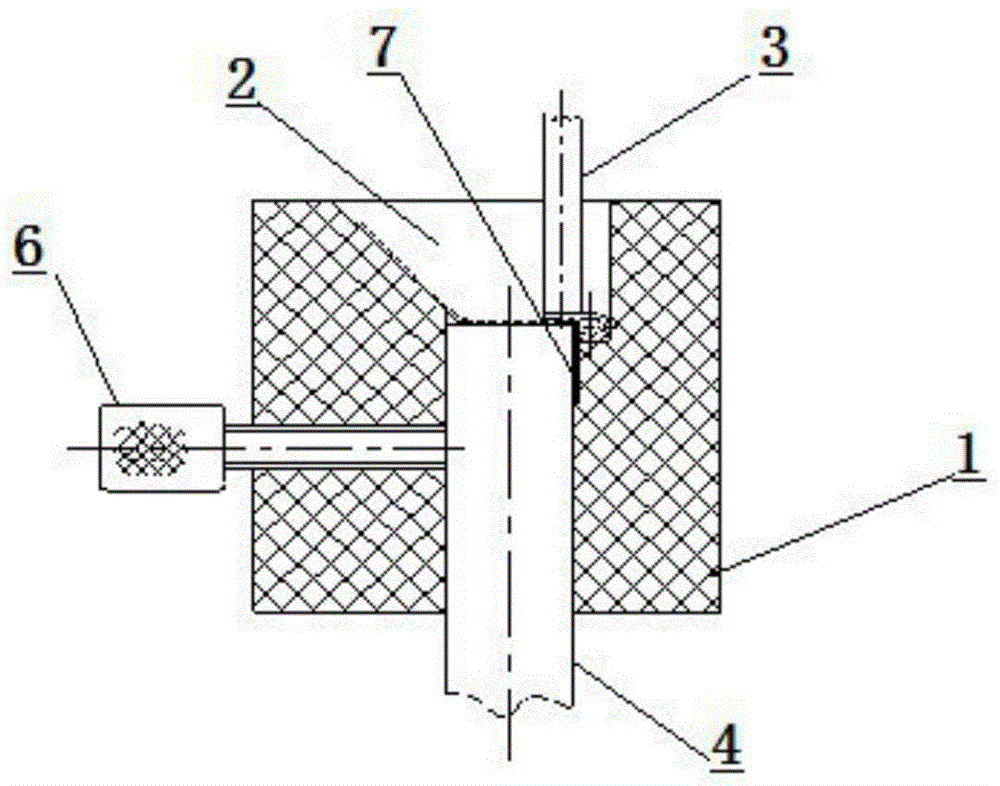

Process for manufacturing power semiconductor module chip with high reliability and high power

PendingCN106252245AReduce high room temperature leakage currentInhibit migrationSemiconductor/solid-state device manufacturingSemiconductor devicesAcid etchingVulcanization

The invention relates to a process for manufacturing a power semiconductor module chip with high reliability and high power. The entre manufacturing process comprises the following procedures: phosphorus diffusion, boron diffusion, titanium nickel silver alloy evaporation, linear cutting, angle grinding, vacuum sintering, acid etching, double-layer colloid joint protection, room temperature vulcanization, high temperature curing, detection and package. The double-layer colloid joint protection, as shown in the figure, comprises: uniformly a coating polyimide (PI) adhesive (41 in the figure) on the table top of the chip to form a dense protective layer, and then using a self-developed automatic gumming tool fixture to coat deep blue silicone rubber (42 in the figure) in batches. According to the process provided by the invention, the advantages of GPP square chips and OJ wafers are combined to improve the manufacturing process of the existing power semiconductor module chip so as to effectively prevent electron transfer and reduce high and normal temperature current leakage of the chip, the dense structure is conducive to subsequent module encapsulation and storage to effectively improve the reliability and yield of products.

Owner:HUANGSHAN 777 ELECTRONICS CO LTD

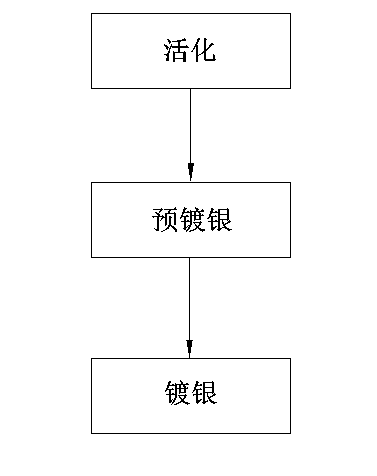

Nickel silvering process in process of electroplating LED (Light Emitting Diode) bracket

The invention discloses a nickel silvering process for replacing copper silvering in the process of electroplating an LED bracket; the nickel silvering process comprises the steps of activating, pre-silvering and silvering, wherein the mixed solution of editpotassium cyanide and potassium carbonate is adopted in the activating process; the concentrations of both editpotassium cyanide and potassium carbonate are 3-20 g / L; the mixed solution of editpotassium cyanide and silver cyanide is adopted in the pre-silvering process; the concentration of editpotassium cyanide is 120-160 g / L; the concentration of silver cyanide is 2.2-4 g / L; the mixed solution of editpotassium cyanide, silver cyanide and potassium hydroxide is adopted in the silvering process; the concentration of silver cyanide is 12-15 g / L; the concentration of editpotassium cyanide is 100-150 g / L; and the concentration of potassium hydroxide is 0.2-0.5 g / L. The nickel silvering process disclosed by the invention is simple in process; silvering is carried out after treating through the process disclosed by the invention; and the LED bracket is non-discolouring in the roasting process only by plating silver of lower thickness.

Owner:甘宁

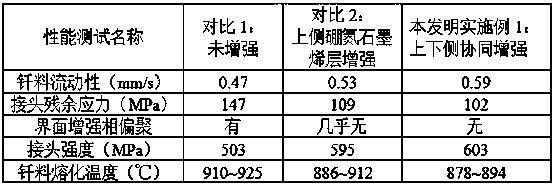

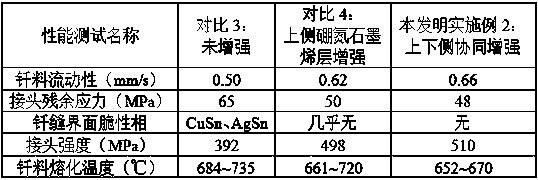

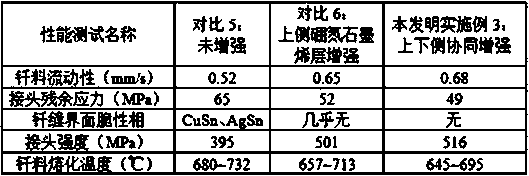

Variable-scale boron-nitrogen graphene modified layer brazing filler metal as well as preparation method and application thereof

ActiveCN110497116AImprove organizationLow melting pointWelding/cutting media/materialsSoldering mediaGas phaseWeld strength

The invention discloses a variable-scale boron-nitrogen graphene modified layer brazing filler metal. The brazing filler metal comprises a variable-scale modified layer composed of a boron-nitrogen graphene reinforced alloy layer which is formed in an upper surface layer, a brazing filler metal layer which is formed in a middle layer and a boron-nitrogen graphene coated foam metal layer which is formed in the lower surface layer, and the preparation method comprises the following steps that a silver brazing material sheet or a gold brazing filler metal sheet is selected, firstly, a boron-nitrogen graphene reinforced nickel-based alloy is sputtered on the upper surface of the brazing filler metal sheet, wherein the nickel-based alloy is a binary or ternary nickel-based alloy consisting of nickel, palladium, gold and copper, then a boron-nitrogen graphene coated foam metal layer is subjected to vapor deposition on the lower surface of the brazing filler sheet, wherein the foam metal is binary nickel-based alloy consisting of nickel-chromium, nickel-gold, nickel-silver or nickel-copper; and the prepared modified layer brazing filler metal can be used for connection of high-nitrogen steel and high-strength steel, the tensile strength of the high-nitrogen steel and the high-strength steel subjected to braze connection is not lower than 500 MPa. The brazing filler metal prepared through the method has a variable-scale layer and can generate a nano-scale effect, so that the mechanical property of the brazing filler metal can be synergistically enhanced, and the welding strength ofthe high-strength steel and the high-nitrogen steel can be improved.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

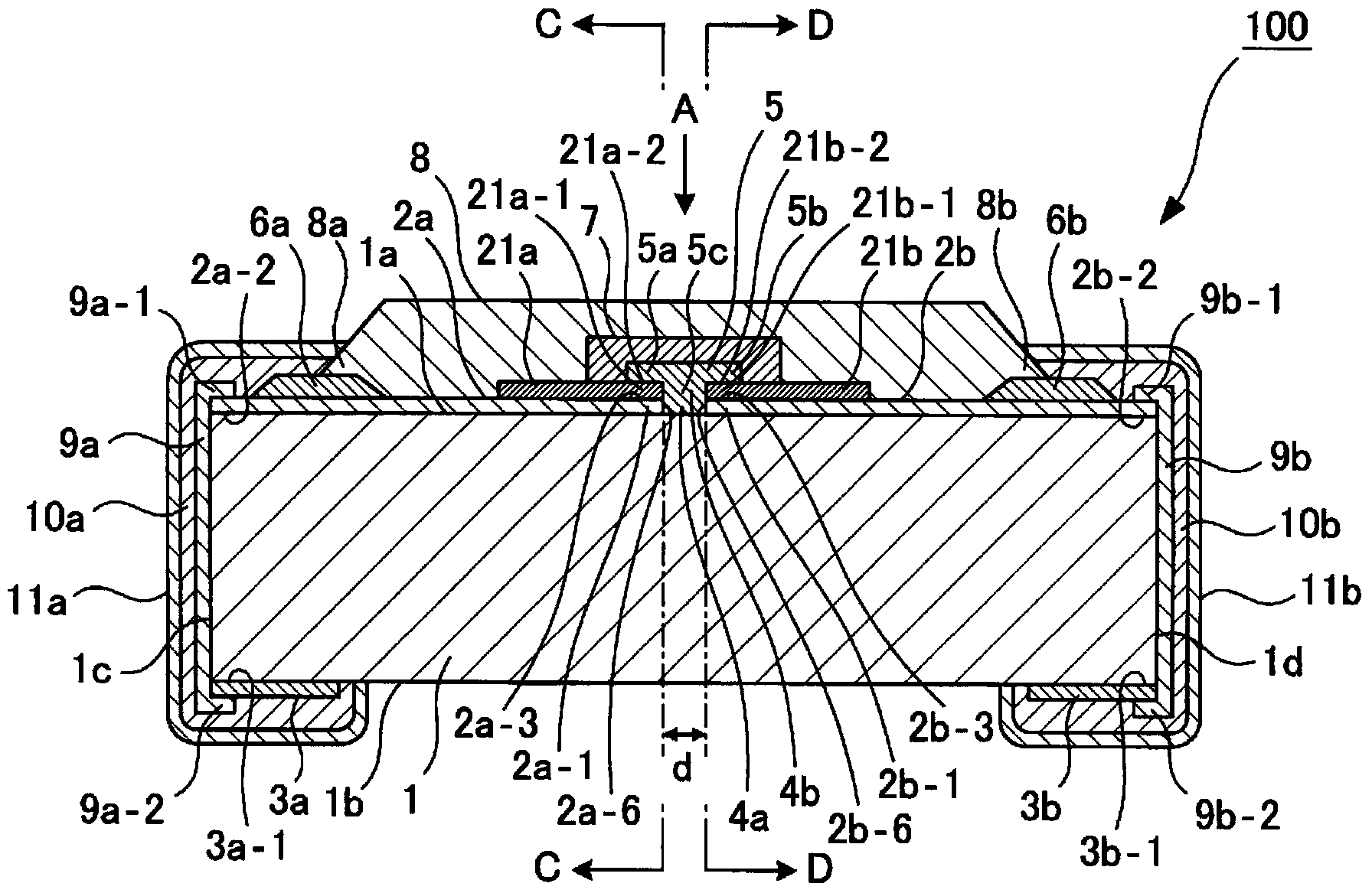

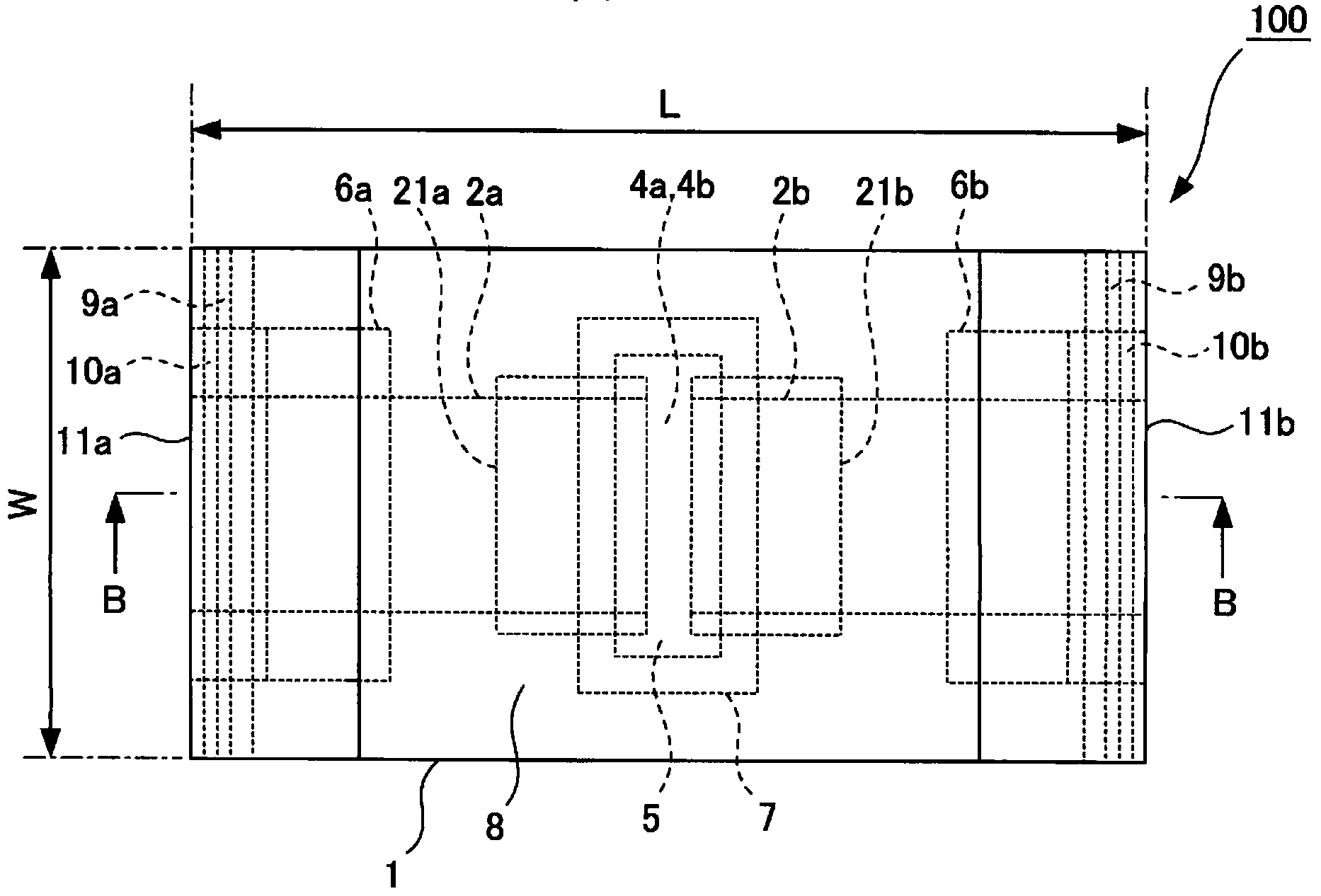

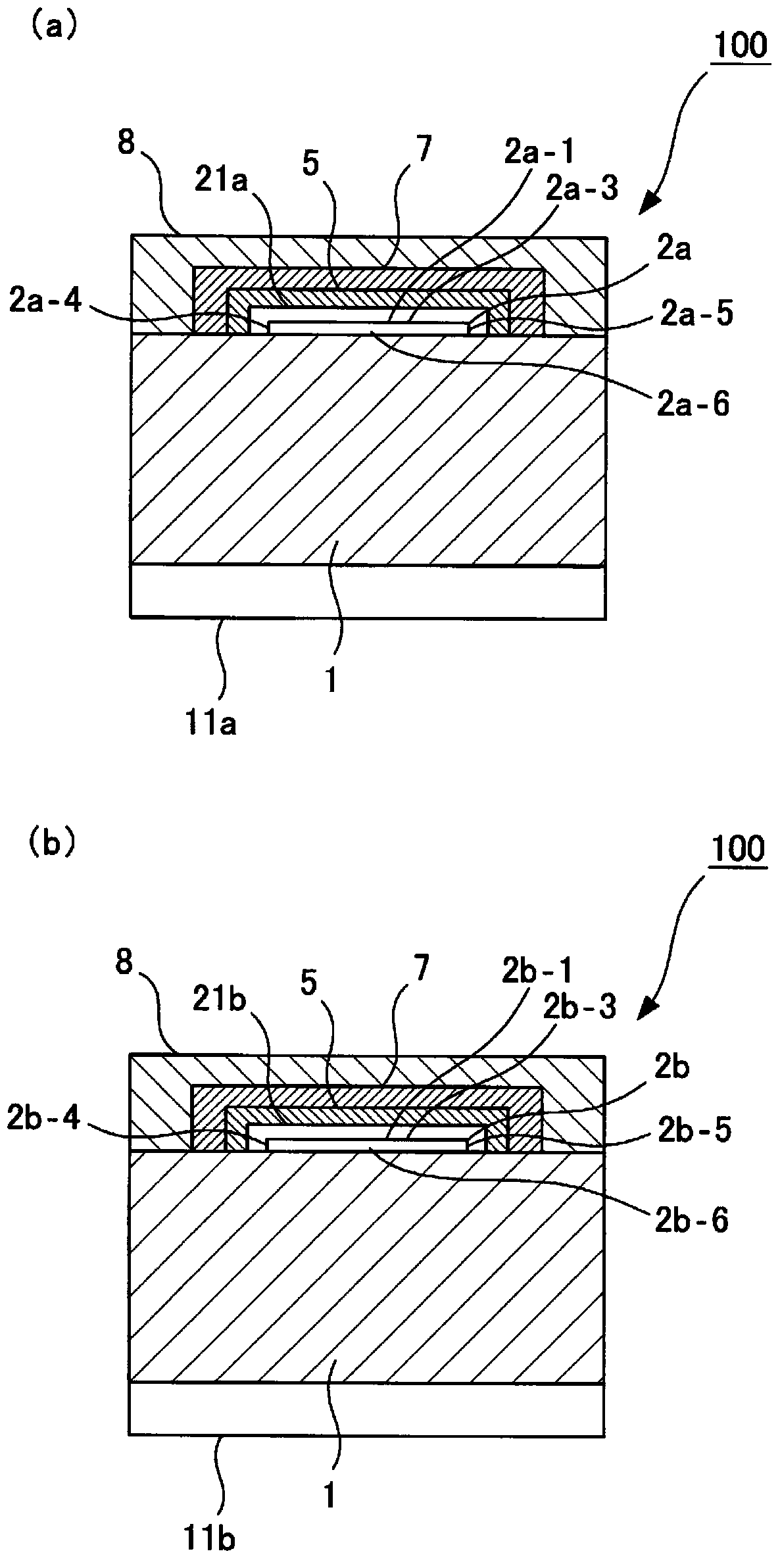

Electrostatic protective component and method for manufacturing same

ActiveCN103918144AReduce manufacturing costNo personal injuryOvervoltage arrestors using spark gapsEngineeringElectrostatic discharge

The purpose of the present invention is to provide an electrostatic protective component and a method for manufacturing the same whereby it is possible to form at low cost a front electrode capable of withstanding electrostatic discharge tests (contact discharge tests) for 500 times or more and maintaining the electrostatic discharge suppression peak voltage below 500 V. For this purpose, an electrostatic protective component (100) is configured with front electrodes (2a, 2b) which are formed on a ceramic substrate (1) and are opposite each other via a gap (4a), glass films (21a, 21b) which are formed on the front electrodes so as to cover the upper surfaces (2a-3, 2b-3) and both side surfaces (2a-4, 2b-4) of the front electrodes and are opposite each other via a gap (4b) communicating with the gap (4a), and an electrostatic protective film (5) which has a center portion (5c) and two side portions (5a, 5b) such that the center portion (5c) is provided at the gaps (4a, 4b) and both side portions are overlapped onto the upper surfaces (21a-2, 21b-2) of the glass films, and the material of the front electrodes is a copper-nickel film or a copper-nickel-silver film.

Owner:KAMAYA ELECTRIC

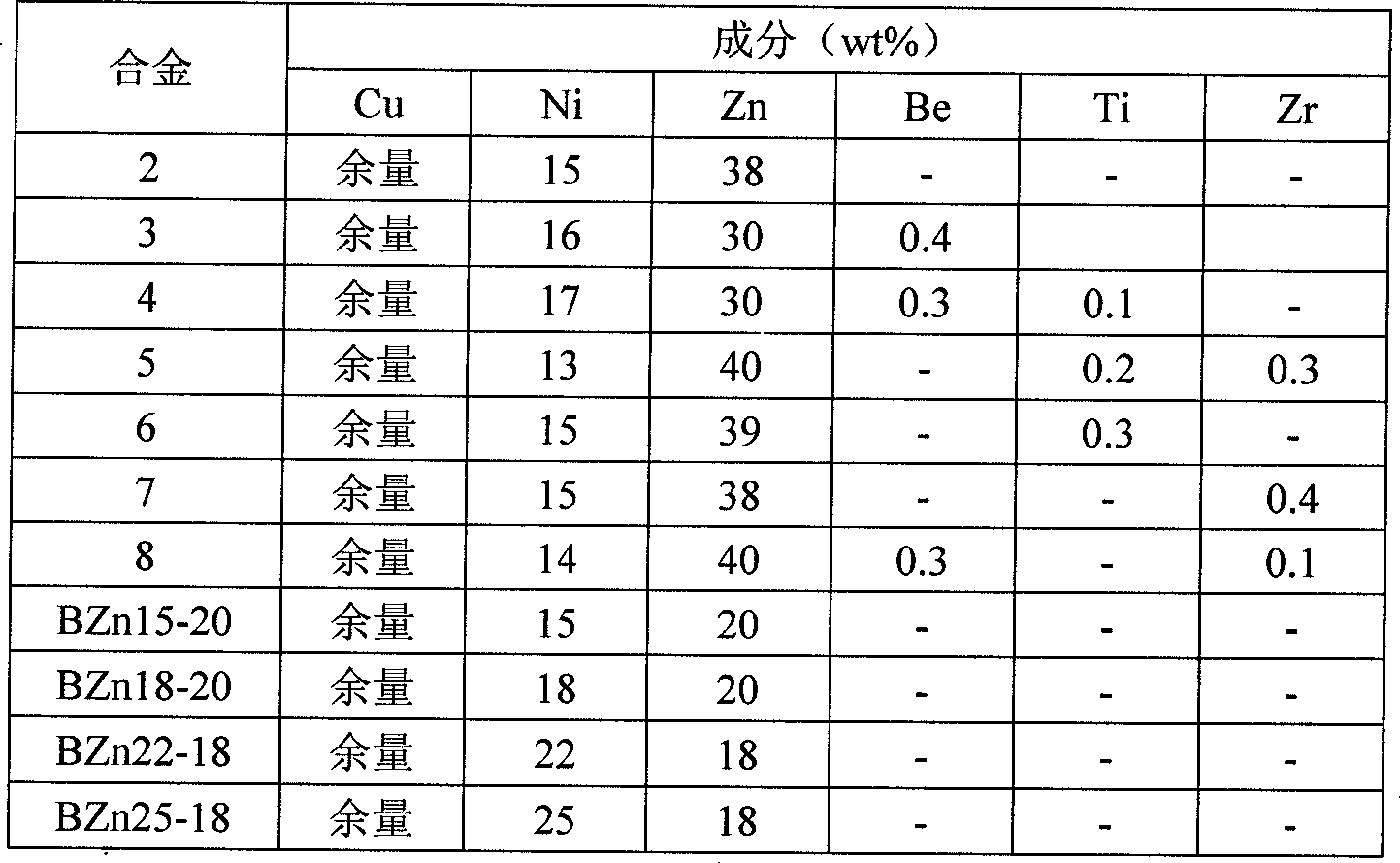

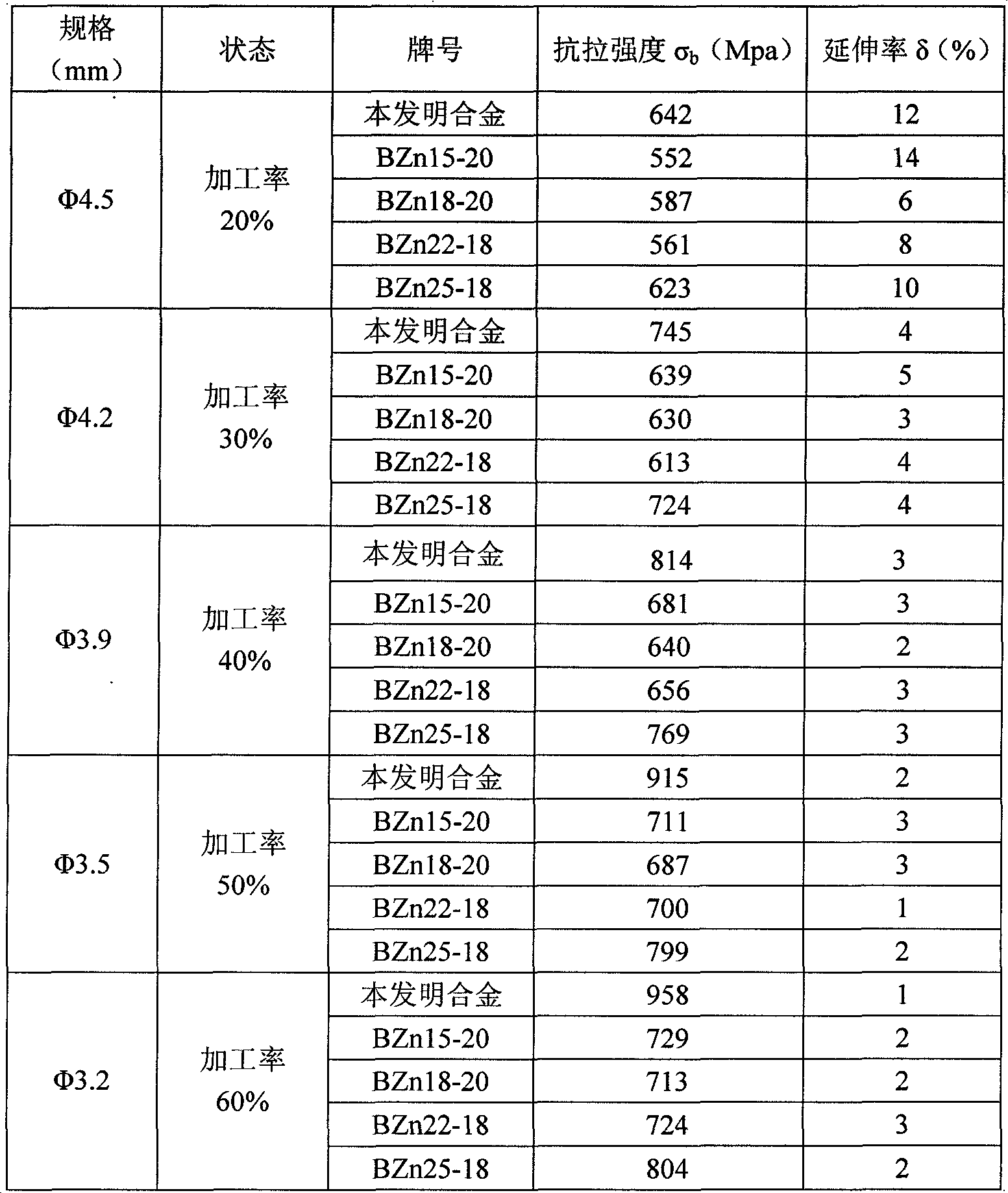

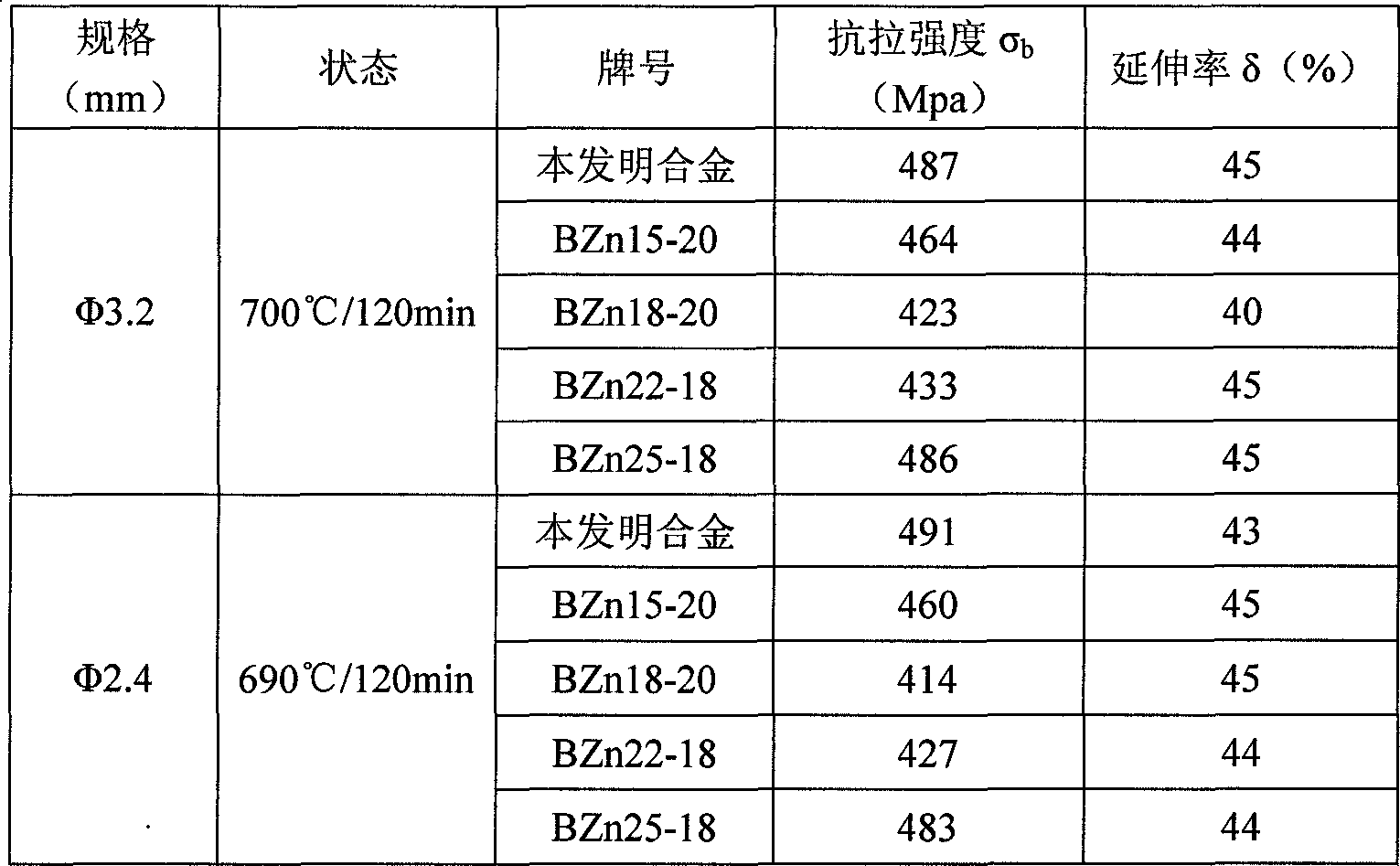

High-strength nickel silver alloy

ActiveCN101148716AHigh tensile strengthGood cold and hot processing performanceChemical compositionCupronickel

The present invention relates to one kind of high strength German silver alloy comprising Ni 13-17 wt%, Zn 28-45 wt%, Be 0-0.5 wt%, Ti 0-0.5 wt%, Zr 0-0.4 wt% and Cu for the rest, with Cu+Zn+Ni content being not lower than 99.5 %. The high strength German silver alloy has high corrosion resistance, weldability and color similar to that of other German silver, even high tensile strength, relatively low cost, and excellent cold and hot working property. It may be applied to replace available German silver in making different elements, and may be also applied in making pressure worked product and cast product.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Nickel-silver corrosive liquid for semiconductor chip

InactiveCN107286939AImprove wettabilityImprove stabilitySurface treatment compositionsSemiconductor chipAcetic acid solution

The invention relates to a nickel-silver corrosion solution for semiconductor chips, which comprises acetic acid solution, nitric acid solution, surfactant, dispersant and complexing agent, and the balance is pure water. The surfactant is a compound mixture of nonionic surfactant and anionic surfactant. The nickel-silver corrosion solution of the present application has high wettability and high stability, and will not corrode the base material of the semiconductor chip while effectively corroding nickel and silver metals. At the same time, the products are dispersed and complexed to make them easy to be cleaned in the subsequent process, which solves the technical problems that the corrosion products are difficult to clean completely and the amount of water used for cleaning is large.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Welding method for relay contact reed assembly

ActiveCN104485261AAvoid overheatingEnhanced diversionElectromagnetic relay detailsCobaltSilver copper

The invention discloses a welding method for a relay contact reed assembly. According to the welding method, a clamping method of an original clamp is changed, and dimension requirements for each position of the contact reed assembly are guaranteed; a traditional welding method of a thin piece and a thick piece is changed, and the thick piece is taken as a main welding face; a traditional welding method employing tungsten copper alloy, chromium zirconium copper alloy and beryllium cobalt copper alloy as electrode materials to weld nickel silver and a silver magnesium nickel assembly is changed, and silver copper alloy and silver chromium alloy are taken as electrode tips to weld the nickel silver and the silver magnesium nickel reed assembly; problems of overhigh temperature of bonding and welding areas of the reed assembly and an electrode in a long term are solved, and burn damage to the reed assembly caused by the electrode in a welding process and crystal boundary organization change are greatly reduced.

Owner:GUIZHOU TIANYI ELECTRICAL

A kind of preparation method of uv photocuring silver-coated nickel conductive paste

ActiveCN105161219BImprove conductivityFor long-term storageNon-conductive material with dispersed conductive materialCable/conductor manufactureWater bathsConductive paste

The invention discloses a preparation method of UV light-cured silver-coated nickel conductive paste. Pretreated nickel powder and silver ammine complex solution are mixed, heated in a water bath at 60-90° C. for 6 hours, and then added with polyvinylpyrrolidone to react for 1-2 hours. , and then centrifuged and cleaned to obtain silver-coated nickel powder; the photosensitive resin and the silver-coated nickel powder were mixed uniformly to obtain a silver-coated nickel conductive adhesive; the conductive adhesive was screen-printed and irradiated under an ultraviolet lamp. The preparation method of the low-temperature polymer conductive paste of the present invention uses precious metal silver to coat base metal nickel, and the preparation process does not require high-temperature sintering and curing, which effectively reduces the production cost; the prepared silver-coated nickel electronic paste not only has excellent electrical conductivity , can also be stored for a long time.

Owner:XI'AN POLYTECHNIC UNIVERSITY

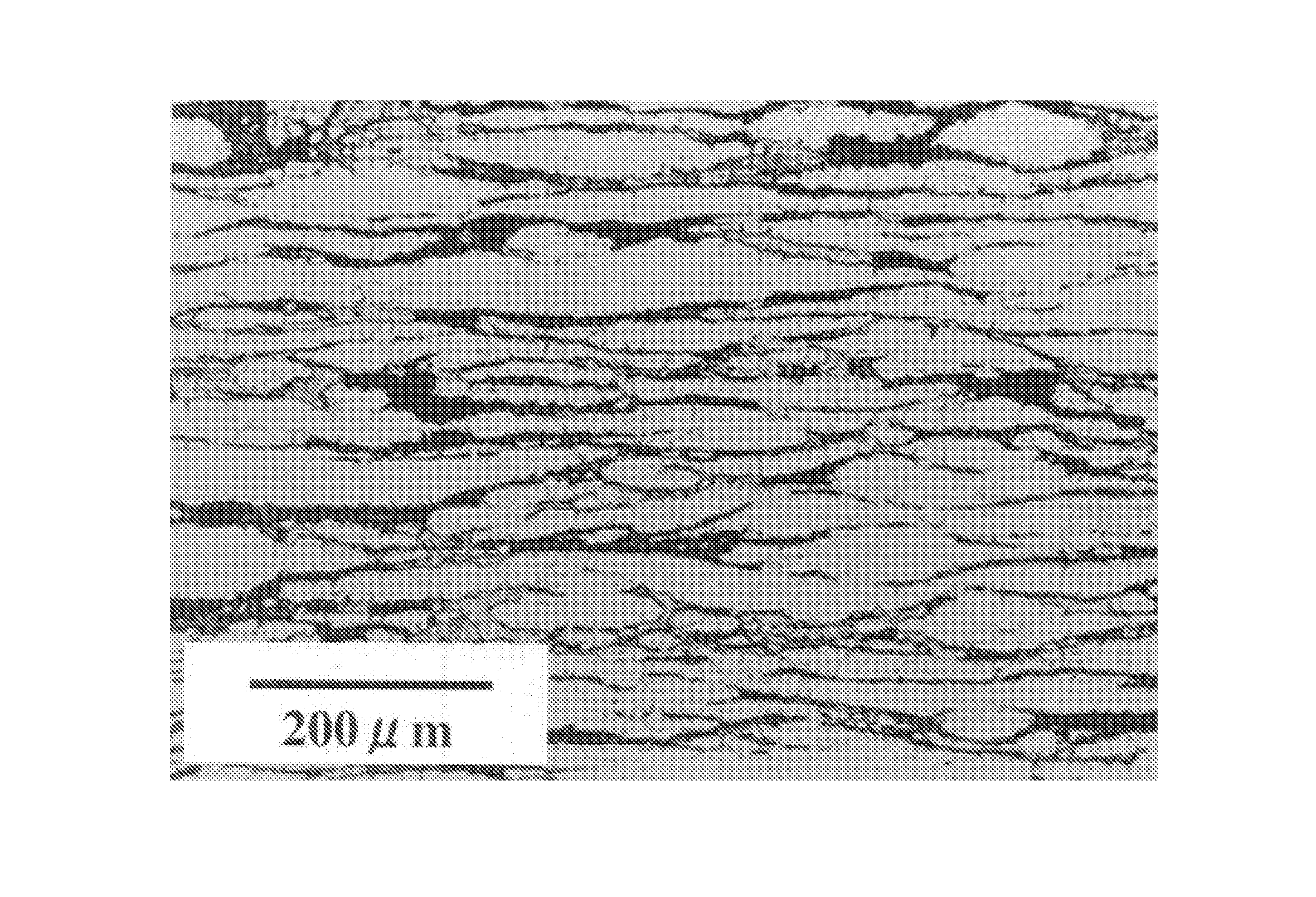

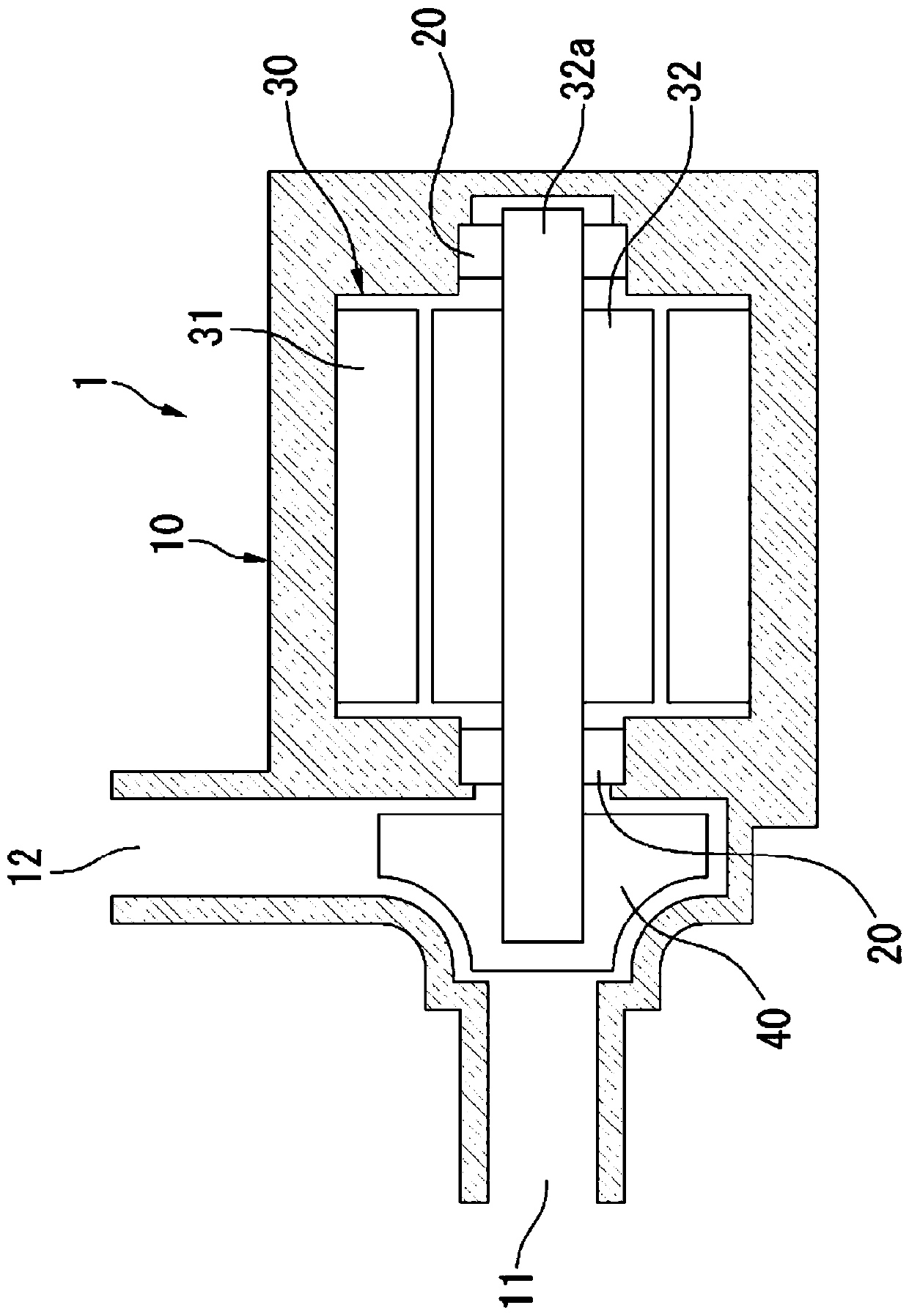

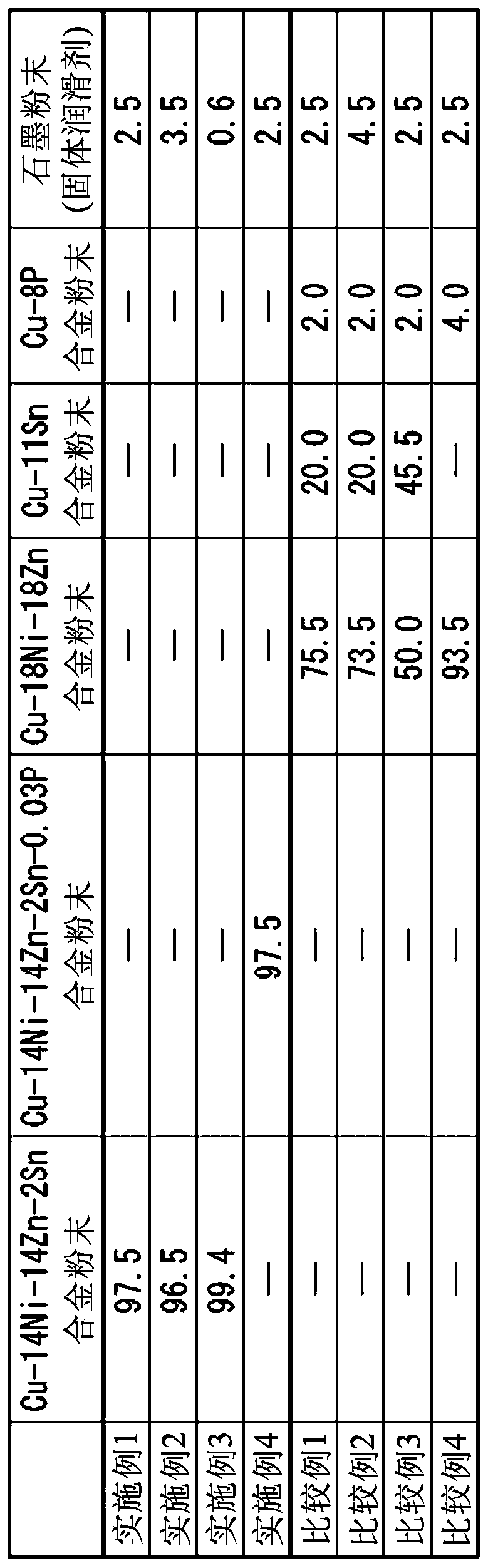

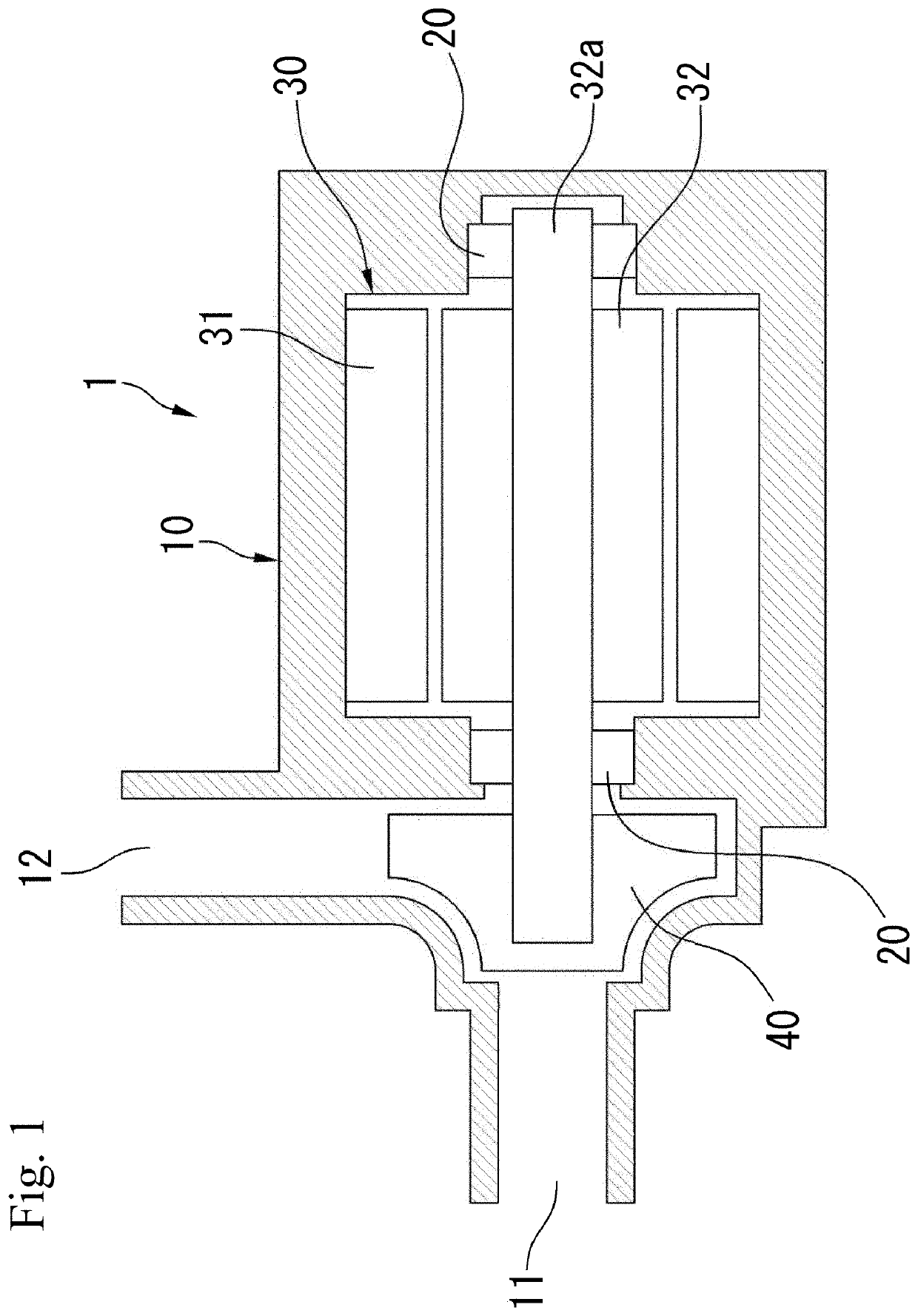

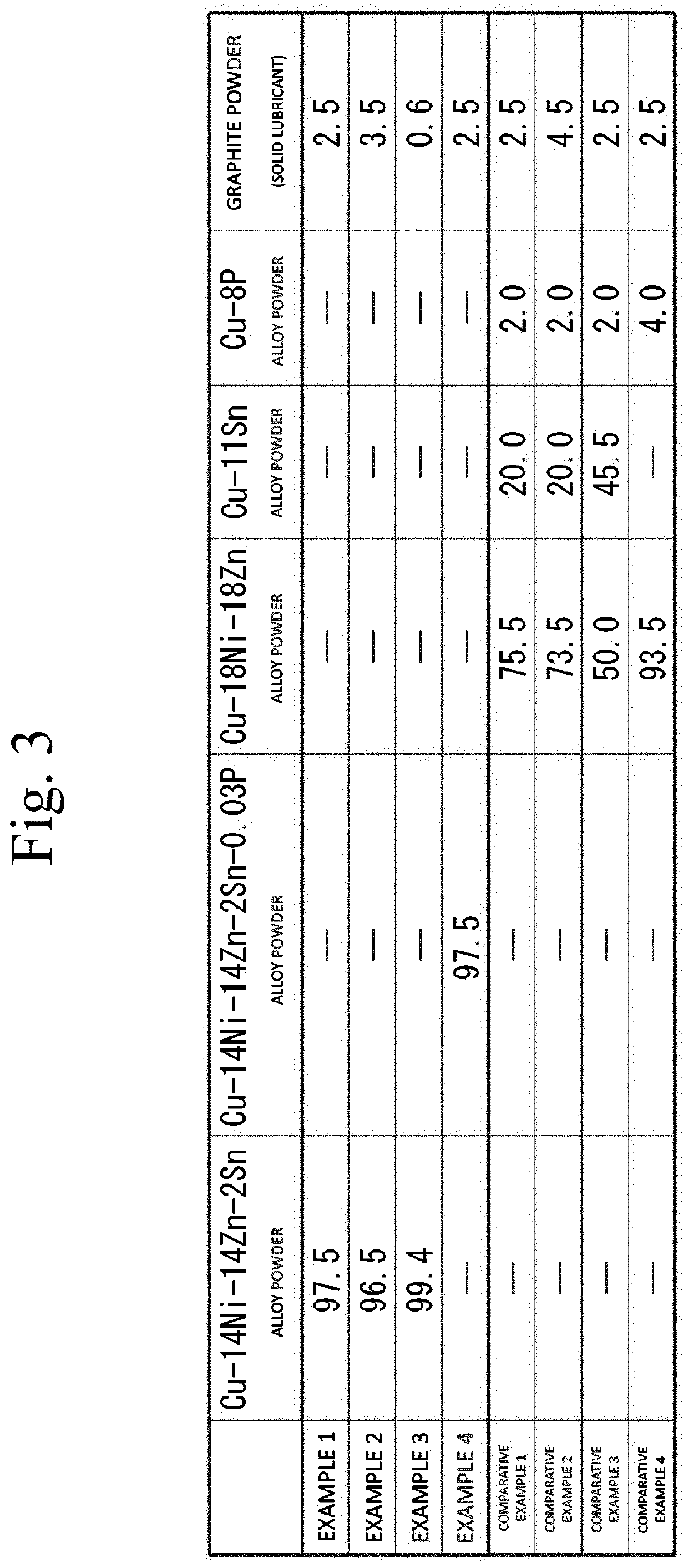

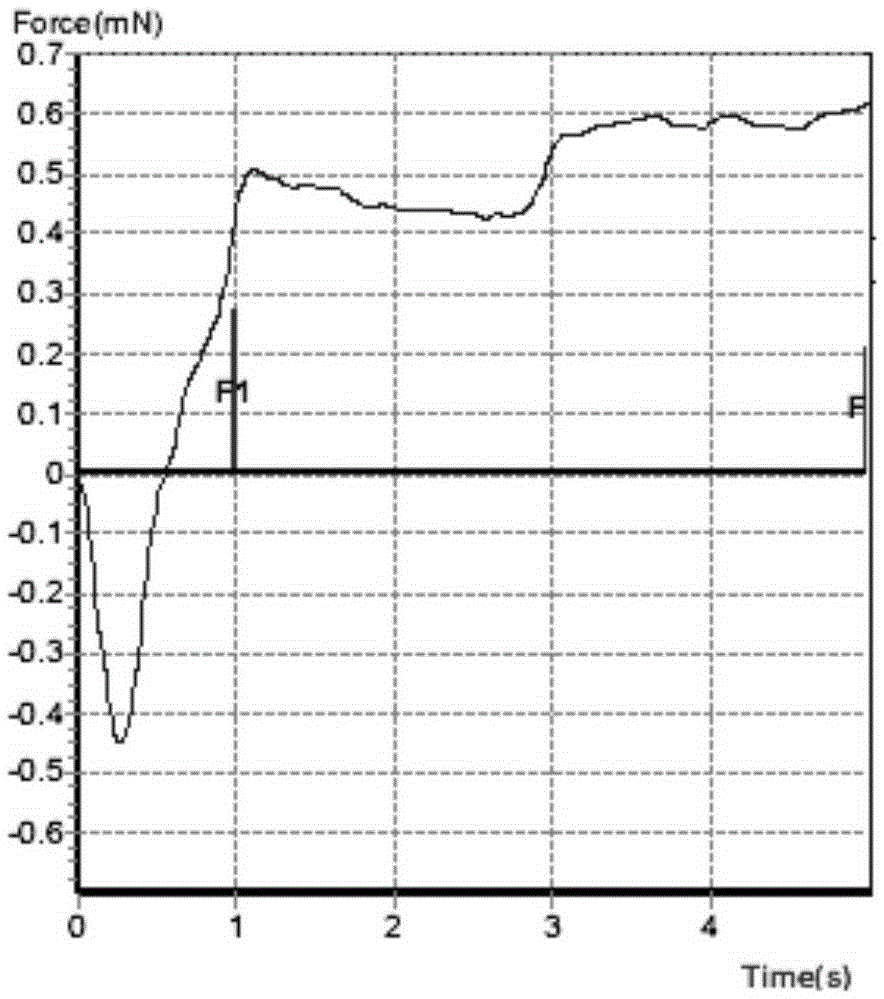

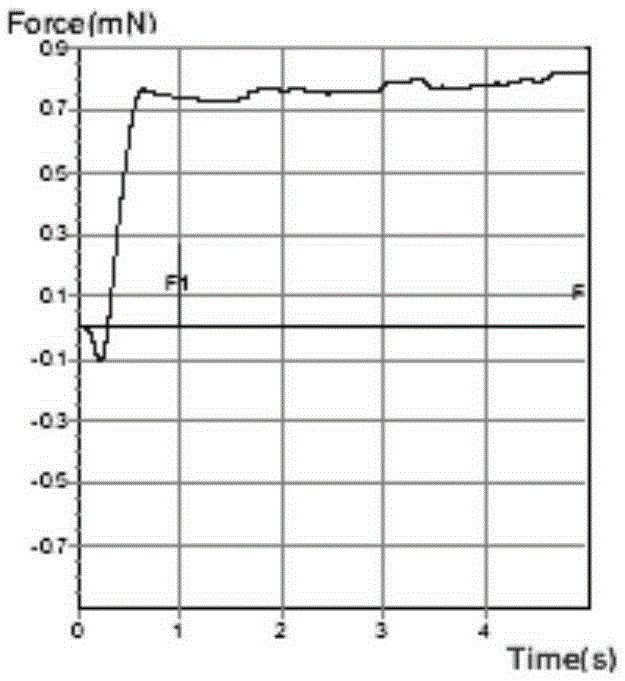

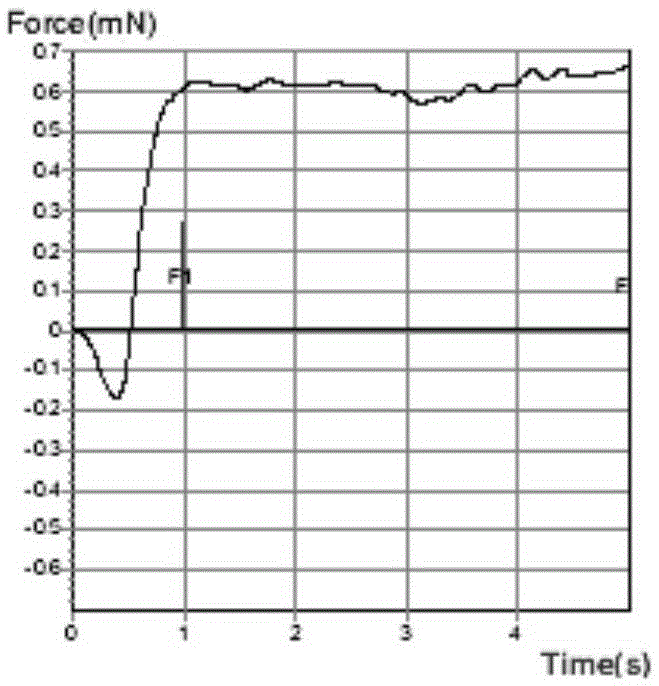

Sintered bearing and method for producing sintered bearing

ActiveCN111587297AAvoid damageHigh mechanical strengthTransportation and packagingShaftsRotational axisMetallurgy

To improve the mechanical strength and vibration resistance of a sintered bearing and to prevent damage to the rotary shaft of the sintered bearing. A sintered bearing 20 according to the present invention is formed of a sintered body that uses nickel silver (Cu-Ni-Zn) as a base material. In this sintered bearing 20, P is not added into the sintered body, or alternatively, the P content in the sintered body is less than 0.05% by mass in terms of the mass ratio to the total mass. Consequently, crystal grains constituting the sintered body can be miniaturized. Specifically, the average crystal grain size of the crystal grains that constitute the sintered body in this sintered bearing 20 is 20 [Mu]m or less. Consequently, it is possible to improve the mechanical strength and vibration resistance, while preventing damage to the rotary shaft.

Owner:PORITE

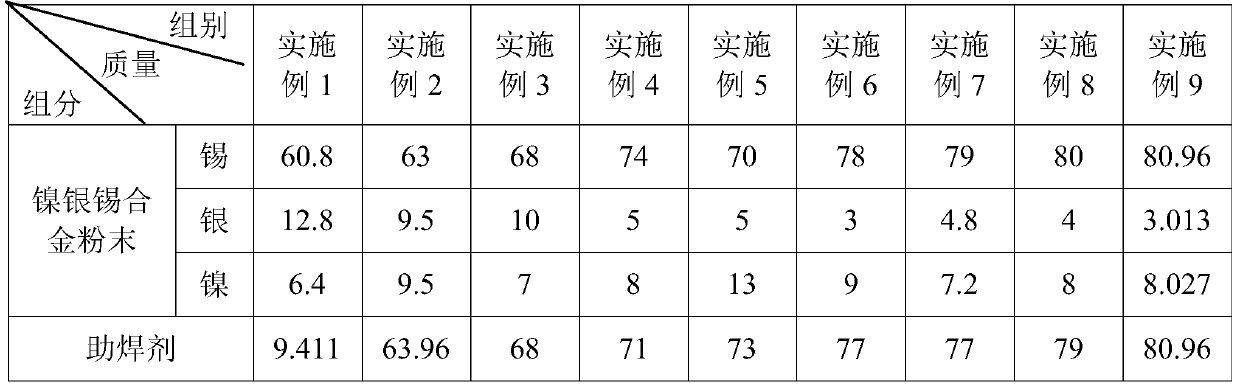

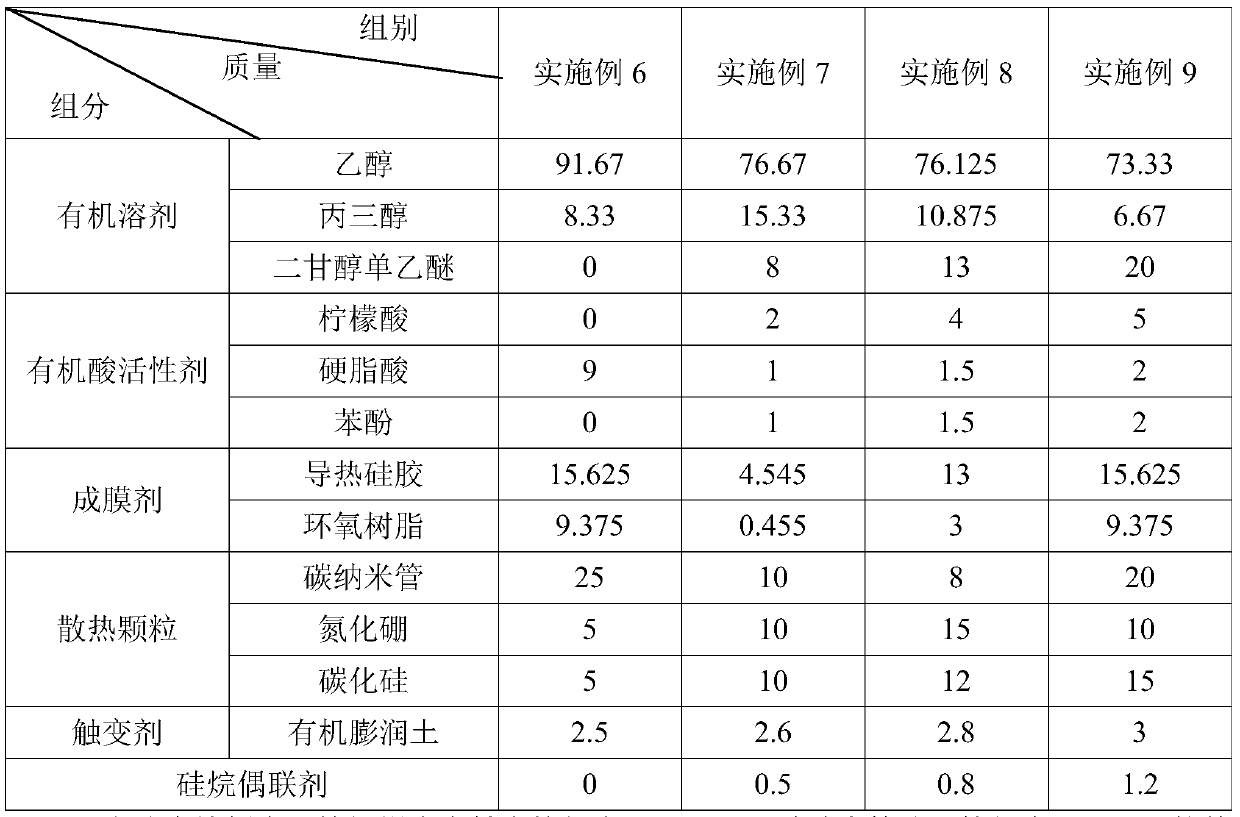

PCB mounting process

ActiveCN110248494AImprove cooling effectAvoid damagePrinted circuit assemblingHeat conductingEngineering

The invention discloses a PCB mounting process and belongs to the technical field of circuit boards, and the problem of the poor heat dissipation in a soldering place of a PCB in the prior art is solved. The mounting process comprises the steps of (S1) printing solder paste on an A side of the PCB and mounting components, (S2) allowing the PCB to pass a reflow oven and performing reflow soldering on the A side, (S3) printing solder paste on a B side of the PCB and mounting components, (S4) allowing the PCB to pass the reflow oven and performing reflow soldering on the B side, and (S5) performing blade coating of heat-conducting silicone grease on soldering parts of the A side and B side after the solder pastes on the A side and the B side of the PCB are cured, wherein the solder pastes comprise the following parts including, by weight, 80 to 92 parts of nickel silver and tin alloy powder, and scaling powder including heat dissipating particles, and the weight ratio of the nickel silver and tin alloy powder to the scaling powder is (8.5-9):1. According to the invention, the heat dissipation performance of the soldering place is improved by using the alloy powder and the heat dissipating particles with high thermal conductivity.

Owner:深圳市英创立电子有限公司

Nickel silver band for piezoelectric crystal oscillator housing and method for producing same

ActiveCN100457938COscillations generatorsPiezoelectric/electrostrictive/magnetostrictive devicesSurface finishEngineering

A packfong belt applying to the shell of piezoelectric crystal oscillator, the material of the copper alloy is prepared by adding nickel and zinc element, and the main chemical constituent is as following: Cu: 62.0 to 66.0 percent; Ni: 16.5 to 19.5 percent; Zn: residual. The workflow is: material checking and accepting - batching - melting - sampling and analyzing (adjusting constituent) - rolling in holding furnace - sampling and analyzing (adjusting constituent) - horizontal continuous casting - batching on - milling - cool cogging rolling - end shearing - intermediate annealing - cold rolling - intermediate annealing - fine rolling - end item annealing - cutting - end item quality inspection - packaging and warehouse-in. The invention settles many technical problems, such as the low tensile strength, the high dimensional tolerance and the poor surface finish quality of the present packfong belt, and it also improves the the shielding property and corrosion resistance.

Owner:中铜(上海)铜业有限公司

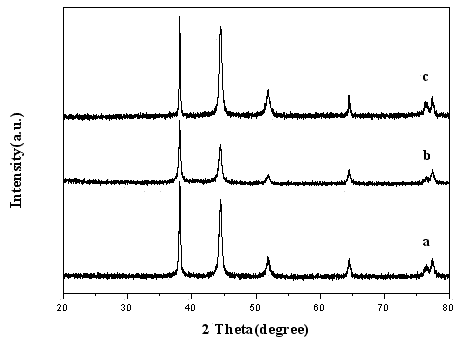

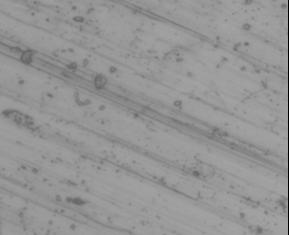

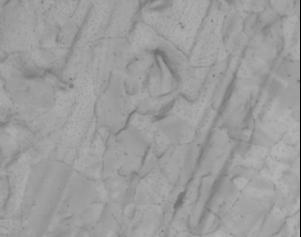

Method for solving high-temperature oxidation of nickel silver C7521

The invention discloses a method capable of enabling a nickel silver C7521 strip not to become yellow at high temperature of 270 DEG C. The root causes of nickel silver yellowing are mainly determined by researching metallographical microscopic structure, analyzing crystal grain spectrum and improving the factors causing nickel silver yellowing. The result proves that control on contents of trace elements in the casting blank, increase of concentration of acid / alkali liquid, proper number of press-down of the brush, decrease of annealing temperature, extension of holding time, production cycle reduction, improvement of every cleaning step and the like are the means for solving the high-temperature yellowing of nickel silver C7521 in actual production.

Owner:CNMC ALBETTER ALBRONZE

High-strength nickel silver alloy

ActiveCN100523237CSuitable for commercial productionHigh tensile strengthChemical compositionCupronickel

The invention relates to a high-strength zinc-nickel-nickel alloy. The chemical composition of the alloy contains: Zn 38%-45%, Ni 13%-17%, and the balance Cu, wherein the alloy composition includes Cu+Zn+ Ni content ≥ 99.5%. Its chemical composition can also contain: one or two of the three elements Be, Ti, and Zr, and the contents of the three elements of Be, Ti, and Zr are respectively: Be 0%~0.5%, Ti 0%~ 0.5%, Zr 0% ~ 0.4%. The alloy can maintain the corrosion resistance, weldability and color of the original various zinc white copper, and has higher tensile strength; because high zinc and other elements are used to replace part of copper and nickel, the cost of the invented alloy is lower than that of commercial zinc Cupronickel can replace the existing zinc-nickel-nickel copper to make various components; the alloy has good cold and hot processing performance, and can be used to produce pressure-processed products and cast products, which is suitable for industrial production.

Owner:NINGBO POWERWAY ALLOY MATERIAL

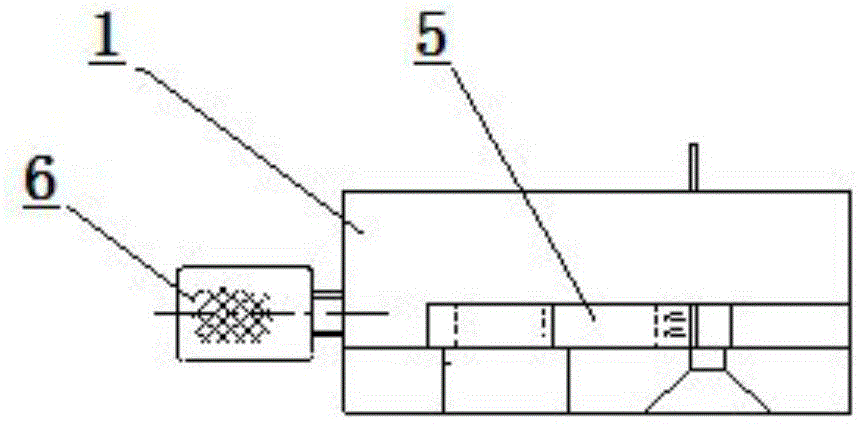

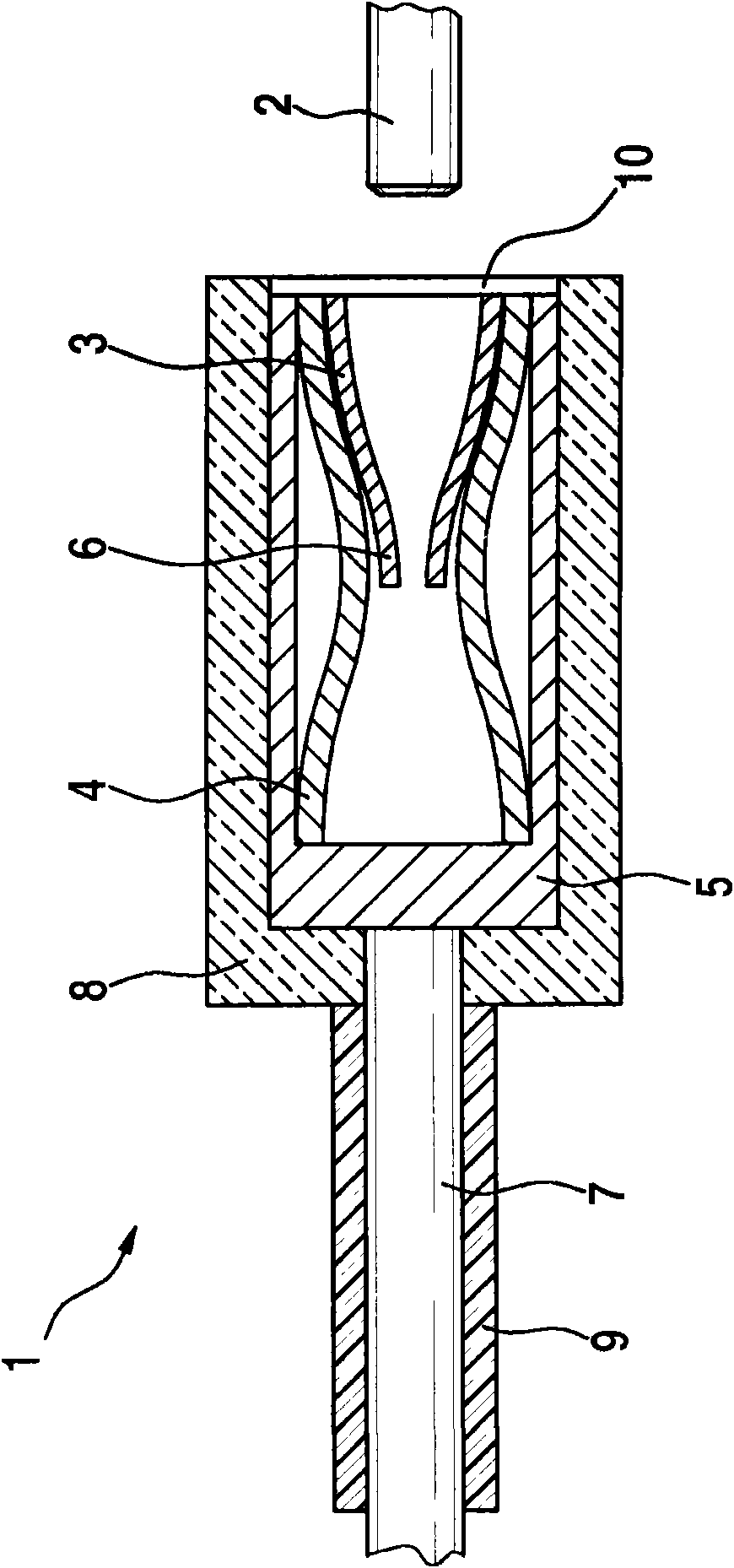

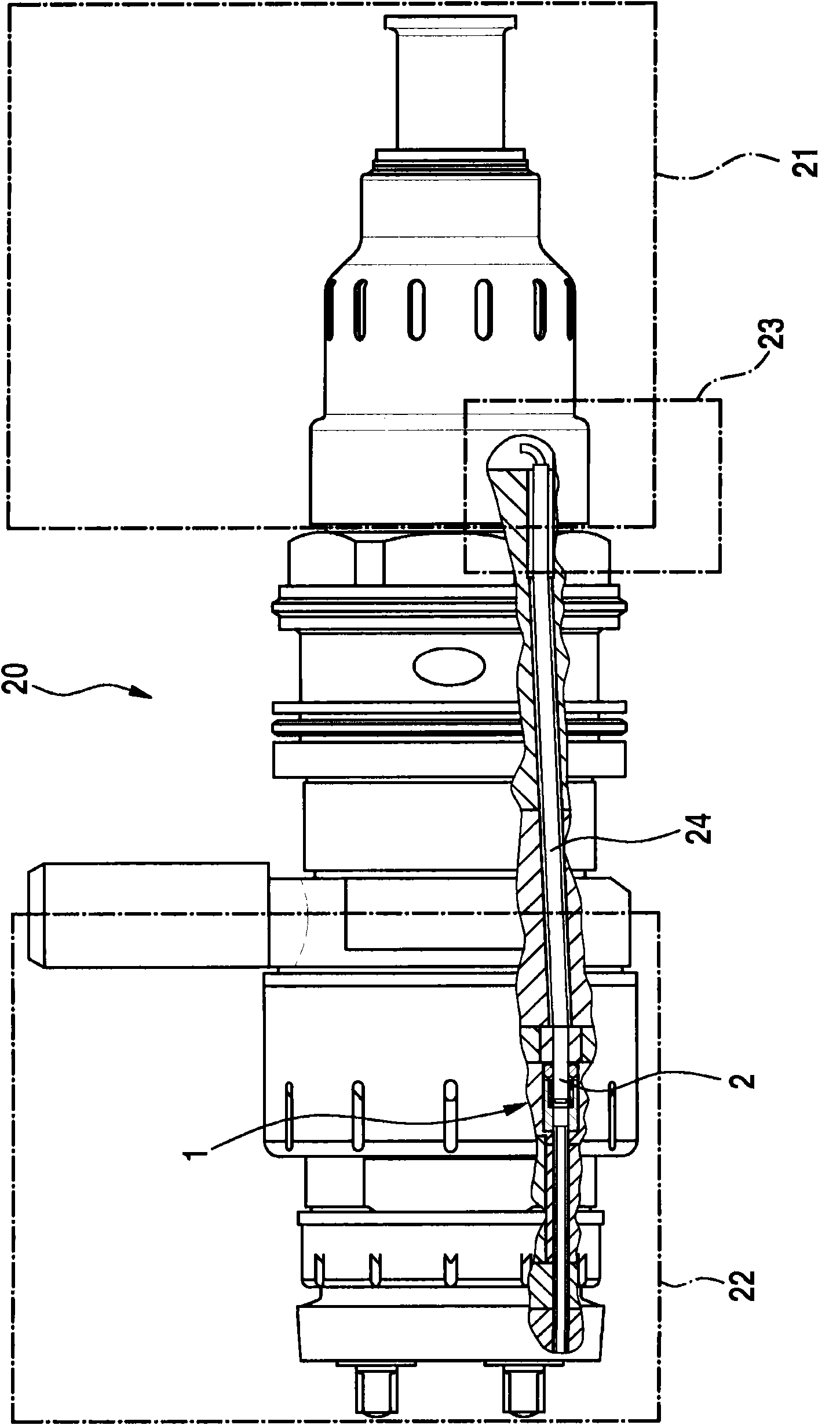

Electrical plug connector as a fuel injector contact for vibration-resistant applications

InactiveCN101689719AWill not cause thermal overheatingCause heat damageCoupling contact membersFuel injection apparatusZincNeedle Shape

An electrical plug connector (1) in the form of a socket contact with a contact inner part (3) for making electrical contact with a pin (2), and with an outer spring (4) which surrounds the contact inner part (3), the contact inner part (3) is, according to the invention, formed from nickel silver.

Owner:ROBERT BOSCH GMBH

Sintered bearing and method for manufacturing sintered bearing

ActiveUS20210040989A1Improve propertiesHigh strengthTransportation and packagingShaftsUltimate tensile strengthNickel silver

A sintered bearing is made of a sintered compact containing nickel silver (Cu—Ni—Zn) as a base. In the sintered bearing, P is not added in the sintered compact. Alternatively, a content of P in the sintered compact is less than 0.05 mass % in terms of mass ratio to a total mass. Consequently, crystal grains constituting the sintered compact can be micronized. In particular, in the sintered bearing, an average crystal particle diameter of the crystal grains constituting the sintered compact is 20 μm or less. Consequently, the mechanical strength and the vibration resisting properties can be improved, and the rotation shaft can be prevented from being damaged.

Owner:PORITE

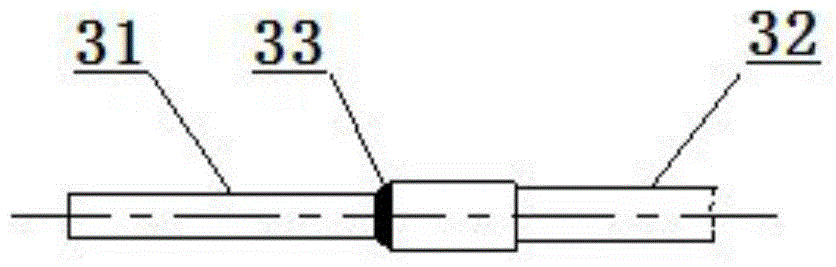

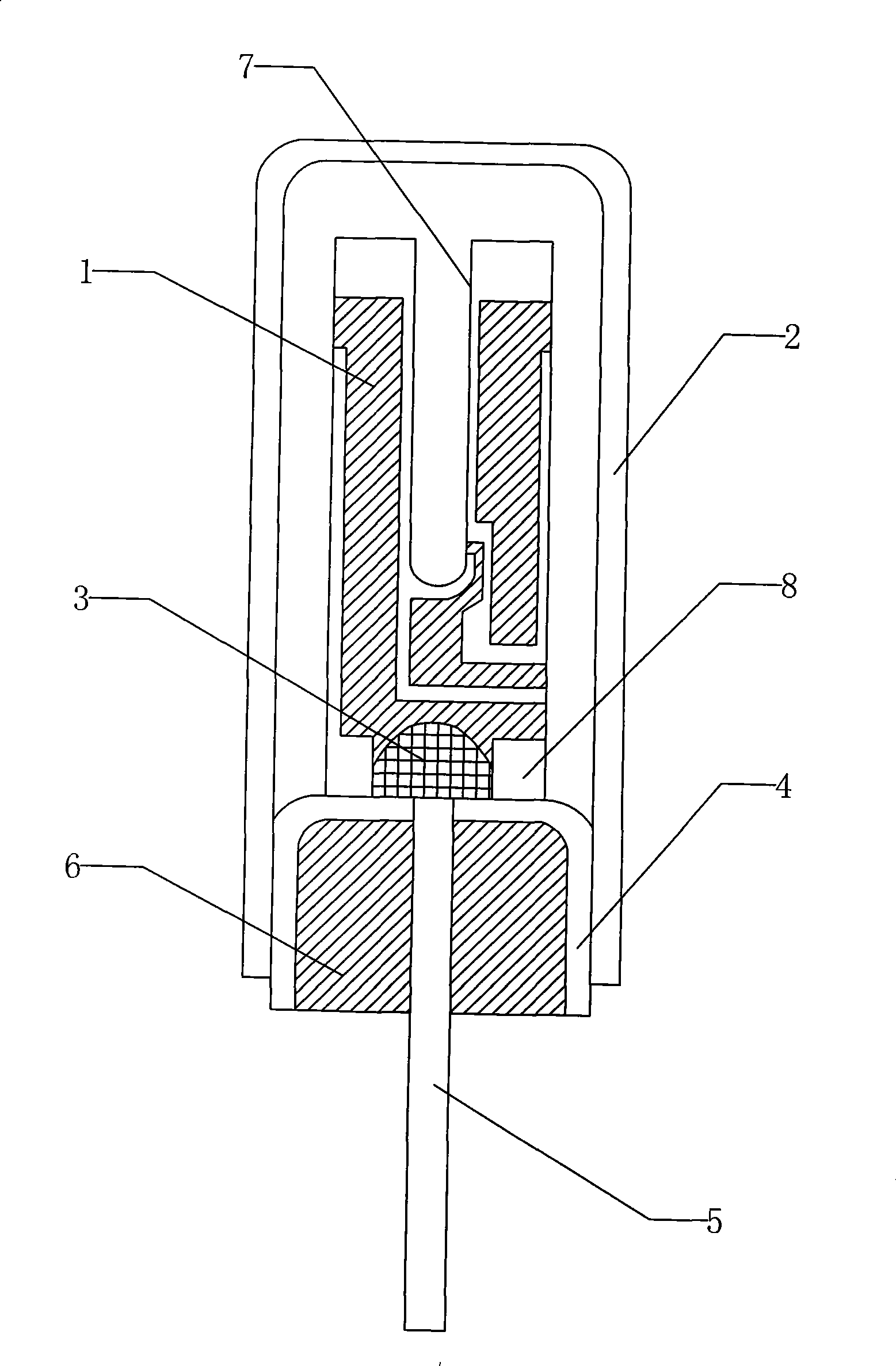

Quartz tuning-fork resonator

The invention relates to a quartz tuning fork resonator, which comprises quartz wafers, a housing, a tin solder wire, a Kovar ring, a lead, a glass bead and tuning fork arms. The quartz tuning fork resonator is characterized in that the entire housing is made of nickel silver; an entire tuning fork is arranged in the housing; the quartz wafers are uniformly distributed on the two tuning form arms respectively; the middle connection section of the tuning form arms has a semi-arc shape; the tin solder wire is inlaid in the center position on the bottom of the tuning fork; and the lead is connected with the lower end of the solder tin wire. The Kovar ring is arranged between the bottom of the tuning form and the glass bead therebelow; the glass bead is sheathed in the Kovar ring; the side surface of the Kovar ring is tightly attached with the housing; and the lead connected with the tin solder wire is extracted out of the housing sequentially through the Kovar ring and the glass bead. The quartz tuning fork resonator has the advantages that: the vibration sections are combined with each other without influencing each other; the adoption of the quartz wafers can enhance the stability and the anti-vibration performance and prolong the service life of the entire resonator; and the resonator has lower vibration frequency, enhanced impact resistance, smaller size and larger power consumption.

Owner:浙江雅晶电子有限公司

Technology for plating silicon wafers with nickel silver

ActiveCN109306481AImprove bindingPrevent oxidationLiquid/solution decomposition chemical coatingBiological activationPre treatment

The invention provides a technology for plating silicon wafers with nickel silver. The technology comprises the following steps of pretreatment: the surfaces of the silicon wafers are cleaned and aresubjected to atomic activation; primary nickel plating: the surfaces of the silicon wafers are plated with primary nickel; nickel sintering: nickel layers and silicon layers are combined; secondary nickel plating: the surfaces of the silicon wafers are plated with secondary nickel; and silver plating: the surfaces of the silicon wafers are plated with silver. The technology has the beneficial effects that the bonding force of the nickel layers and the silicon layers can be effectively increased through secondary nickel plating, oxidation of the nickel layers can be effectively prevented through silver plating, the bonding force of the silicon wafers and soldering paste can be higher through nickel silver plating, silver nitrate is used as a silver plating solution and is safer and more reliable in production, transportation and storage processes, the production cost is saved, and the nickel silver plating technology has the advantages of low production cost, high reliability and long service life of the silicon wafers.

Owner:TIANJIN HUANXIN TECH DEV

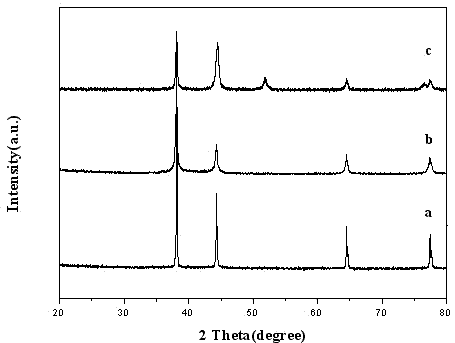

A Production Process for Improving the Performance of Lead-free Soldering of Zinc White Copper Strip

ActiveCN103628008BUniform tissueImprove lead-free solder performanceManufacturing technologySurface roughness

The invention discloses a manufacturing technology for improving a Pb-free solder property of a packfong strip. The manufacturing technology of the packfong strip comprises the steps of casting, surface milling, rough rolling, edge cutting, intermediate annealing, degreasing and cleaning, intermediate rolling, intermediate annealing, degreasing and cleaning, finished product rolling, finished product annealing, stretch bending and straightening, finished product cleaning and itemizing and storing, the finished product rolling working rate is 30 to 45%, and the roller surface roughness Ra adopted in the finished product rolling is less than or equal to 0.1[mu]m and larger than or equal to 0.3 [mu]m; the annealing temperature of the finished product is set to be 425 to 535 DEG C, and heat preservation is performed for 7 to 12 hours at the temperature; the concentration of the finished product cleaning acid liquor is controlled to be 4 to 9%; all of the finished product rolling, the finished product annealing and the finished product acid liquor cleaning improve the Pb-free solder property of the packfong strip.

Owner:安徽鑫科铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com