Method of preparing nickel-silver nuclear shell structure nano-particles

A nanoparticle, core-shell structure technology, applied in the direction of coating, etc., can solve the problems of low metal shell coating and uneven coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

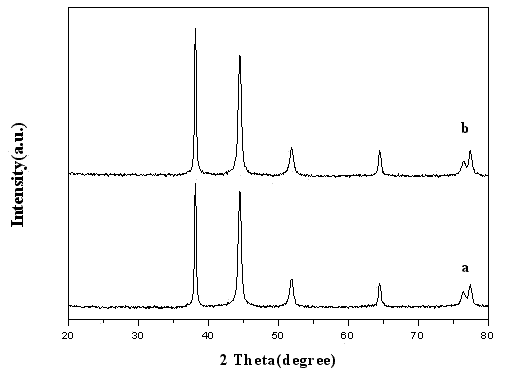

[0027] Example 1: 20°C, 30°C, 40°C

[0028] The nickel powder was washed with dilute hydrochloric acid to remove oxides, washed with deionized water and then added to SnCl with a mass fraction of 5%. 2 Soak in hydrochloric acid solution for 5min, then wash with deionized water until Cl-free - ; Add 50mL of 0.04~0.08mol / L AgNO to the activated nickel powder 3 Ultrasound in the solution or silver ammonia solution for 30min, the ratio of the amount of nickel to silver is 1:0.4, so that the nickel powder is evenly dispersed in the solution, mechanically stirred for 24 hours, and the supernatant is titrated with dilute hydrochloric acid to see if there is a white precipitate, which can be checked With or without Ag + exists, so as to determine whether the reaction is complete; after the reaction is complete, separate the product with a magnet, wash it with deionized water and absolute ethanol, and dry it in vacuum at 40°C for 12 hours to obtain the product. The complexing agent i...

Embodiment 2

[0033] The nickel powder was washed with dilute hydrochloric acid to remove oxides, washed with deionized water and then added to SnCl with a mass fraction of 15%. 2 Soak in hydrochloric acid solution for 5min, then wash with deionized water until Cl-free - Add the activated nickel powder into 50mL of 0.04-0.08mol / L silver ammonia solution for 30-60min sonication to disperse the nickel powder evenly in the solution, and the nickel-silver molar ratio is 1:0.3, 1:0.5, 1:0. 0.8, mechanically stirred for 24 hours, the supernatant was titrated with dilute hydrochloric acid to see if a white precipitate was formed, which can be used to check whether there is Ag + Existence, so as to determine whether the reaction is complete; after the reaction is complete, separate the product with a magnet, wash with deionized water and absolute ethanol, and vacuum dry at 40°C for 12 hours to obtain the product.

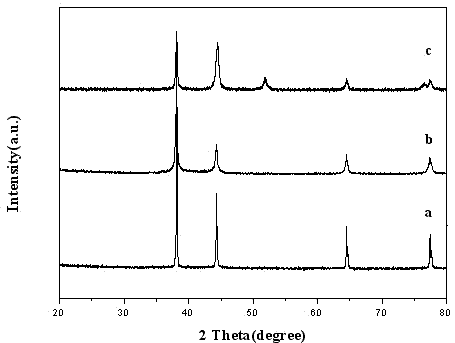

[0034] Samples were characterized by XRD:

[0035] image 3 In order to change th...

Embodiment 3

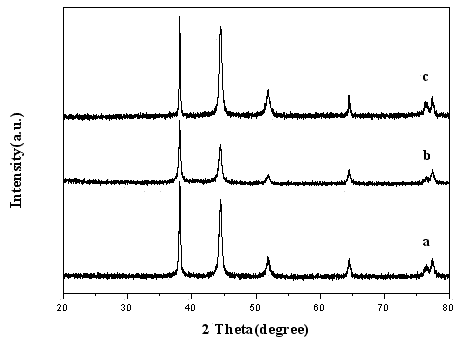

[0038] The nickel powder was washed with dilute hydrochloric acid to remove oxides, washed with deionized water and then added to SnCl with a mass fraction of 10%. 2 Soak in hydrochloric acid solution for activation for 8 minutes, then wash with deionized water until Cl-free - ; Add the activated nickel powder into a flask filled with 50mL of 0.06~0.10mol / L silver ammonia solution, the ratio of the amount of nickel to silver is 1:0.4, sonicate for 30~60min in a water bath, and the temperature of the water bath is 20°C , 30°C, 40°C, disperse the nickel powder evenly in the solution, stir it mechanically for 24 hours, titrate the supernatant with dilute hydrochloric acid to see if there is white precipitate, you can check whether there is Ag + Existence, so as to determine whether the reaction is complete; after the reaction is complete, separate the product with a magnet, wash with deionized water and absolute ethanol, and vacuum dry at 40°C for 12 hours to obtain the product. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com