Halogen-free flame-retardant epoxy resin composition and application thereof

A technology of epoxy resin and epoxy resin solution, applied in the direction of printed circuit parts, etc., can solve the problems of unstable product quality, inability to use in large quantities, and expensive products, and achieve good reactivity, good flame retardancy, and peeling. high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

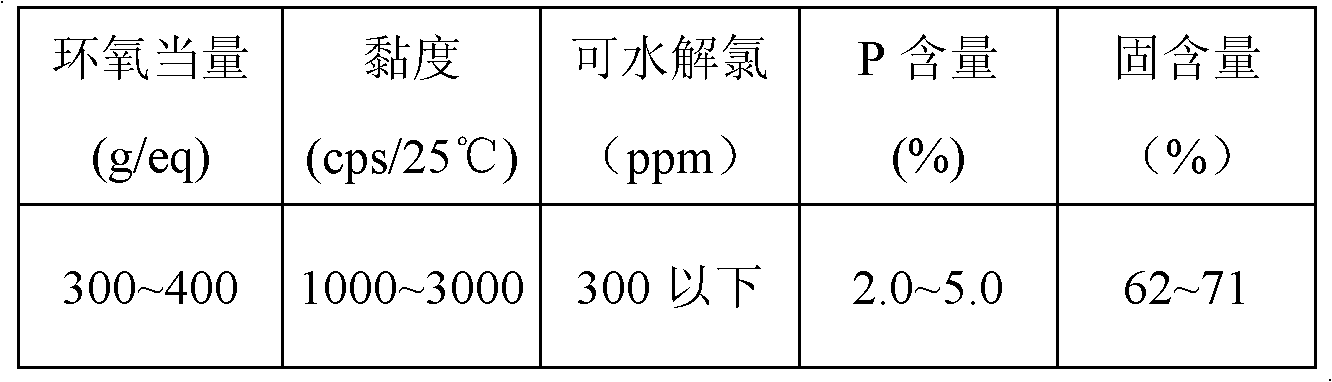

[0034] (1) Preparation of phosphorus-containing epoxy resin butanone solution:

[0035] Add 41 parts by weight of novolac epoxy resin and 17 parts by weight of DOPO into the reaction tank, add 0.010 parts by weight of catalyst triphenylphosphine at 120 ° C, react at 175 ° C for 2.5 hours, and then mix in 15 parts by weight of epoxy equivalent Greater than the large molecular weight solid bisphenol A type epoxy resin of 450g / eq, the o-cresol type epoxy resin of 23 weight parts and the solid content of 5 weight parts are the tetraphenol ethane tetraglycidyl ether acetone solution of 70%, and then Dissolve it with methyl ethyl ketone to form a solution with a solid content of 70%.

[0036] (2) Preparation of halogen-free flame retardant epoxy resin composition:

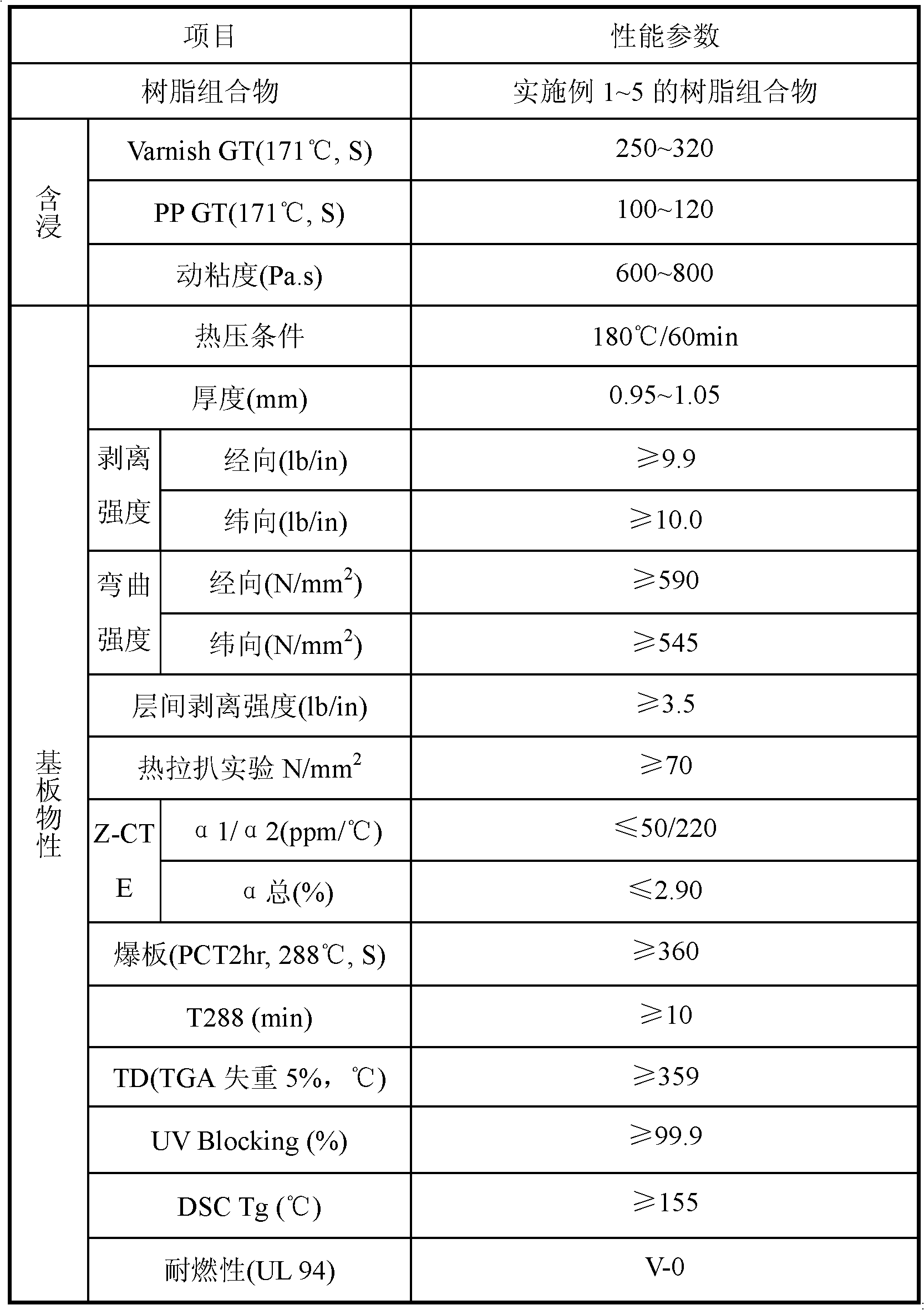

[0037] Take by weighing the phosphorus-containing epoxy resin methyl ethyl ketone solution and dicyandiamide curing agent obtained in step (1) as shown in the table below, and add curing accelerator, inorganic filler an...

Embodiment 2

[0043] (1) Preparation of phosphorus-containing epoxy resin butanone solution:

[0044] Add 45 parts by weight of novolac epoxy resin and 18 parts by weight of DOPO to the reaction tank, add 0.010 parts by weight of catalyst triphenylphosphine at 120 ° C, react at 175 ° C for 2.5 hours, and then mix in 17 parts by weight of epoxy equivalent Greater than the large molecular weight solid bisphenol A type epoxy resin of 450g / eq, the o-cresol type epoxy resin of 26 weight parts and the solid content of 7 weight parts are the tetraphenol ethane tetraglycidyl ether acetone solution of 70%, and then Dissolve it with methyl ethyl ketone to form a solution with a solid content of 70%.

[0045] (2) Preparation of halogen-free flame retardant epoxy resin composition:

[0046] Take by weighing the phosphorus-containing epoxy resin methyl ethyl ketone solution and dicyandiamide curing agent obtained in step (1) as shown in the table below, and add curing accelerator, inorganic filler and ...

Embodiment 3

[0051] (1) Preparation of phosphorus-containing epoxy resin butanone solution:

[0052] Add 35 parts by weight of novolac epoxy resin and 15 parts by weight of DOPO into the reaction tank, add 0.020 parts by weight of catalyst triphenylphosphine at 120°C, react at 175°C for 2.5h, and then mix in 15 parts by weight of epoxy equivalent Greater than the large molecular weight solid bisphenol A type epoxy resin of 450g / eq, the o-cresol type epoxy resin of 22 weight parts and the tetraphenol ethane tetraglycidyl ether acetone solution of 70% solid content of 5.3 weight parts, use again Butanone dissolves to a 70% solids solution.

[0053] (2) Preparation of halogen-free flame retardant epoxy resin composition:

[0054] Take by weighing the phosphorus-containing epoxy resin methyl ethyl ketone solution and dicyandiamide curing agent obtained in step (1) as shown in the table below, and add curing accelerator, inorganic filler and an appropriate amount of solvent, and mix uniformly:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com