A Production Process for Improving the Performance of Lead-free Soldering of Zinc White Copper Strip

A production process and technology of lead-free solder, which is applied in the field of zinc-nickel-nickel strip processing, can solve the problems of unstable performance of lead-free solder, low test pass rate, small tin pulling force, etc., to improve the performance of finished lead-free solder, improve Lead-free solder performance, effect of improvement of lead-free solder performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The production process for improving the performance of lead-free soldering of zinc-nickel-nickel strips. The production process of zinc-nickel-nickel strips is: casting→face milling→rough rolling→edge trimming→intermediate annealing→degreasing cleaning→intermediate rolling→intermediate annealing→degreasing cleaning→finished product Rolling→annealing of finished products→bending and straightening→cleaning of finished products→strip storage, the rolling processing rate of finished products is 30%~45%, and the surface roughness of the rolls used for rolling of finished products is 0.1μm≤Ra≤0.3μm; In the annealing process, the annealing temperature is set at 425-535°C and kept at this temperature for 7-12 hours; in the finished product cleaning process, the mass concentration of the finished product cleaning acid is controlled at 4-9%.

[0036] The annealing of the finished product is preferably carried out in the annealing furnace, and the gas atmosphere in the annealing f...

Embodiment 2

[0039] The processing technology for improving the performance of lead-free soldering of zinc-nickel-nickel strips. The production process of zinc-nickel-nickel strips is: casting→face milling→rough rolling→edge trimming→intermediate annealing→degreasing and cleaning→intermediate rolling→intermediate annealing→degreasing and cleaning→ Finished product rolling→finished product annealing→stretch bending straightening→finished product cleaning→strip warehousing; the finished product is rolled with a processing rate of 45%; the finished product is rolled with a roll with a surface roughness Ra=0.3μm; the finished product is annealed in an annealing furnace Carry out, the temperature is set at 440°C, and the gas atmosphere in the annealing furnace is 75%H 2 +25%N 2 , and heat treatment at this temperature for 12 hours, and the finished product is cleaned with an acid solution of H 2 SO 4 , the acid concentration is 9%.

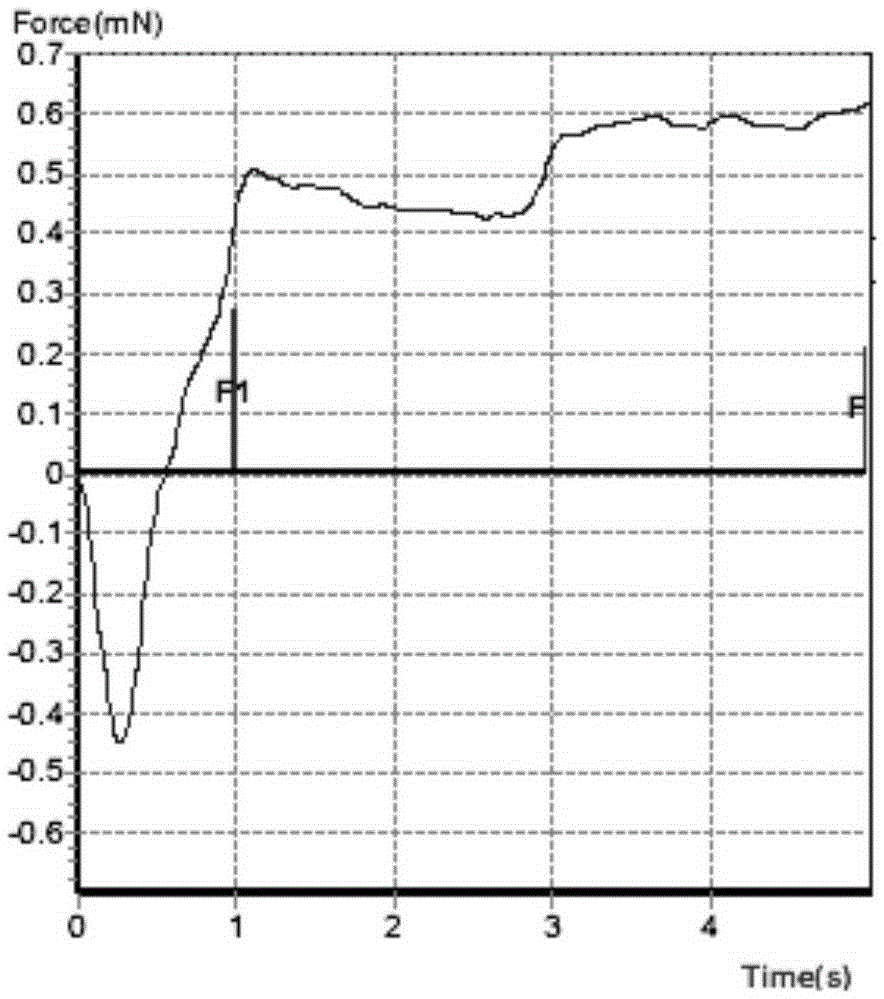

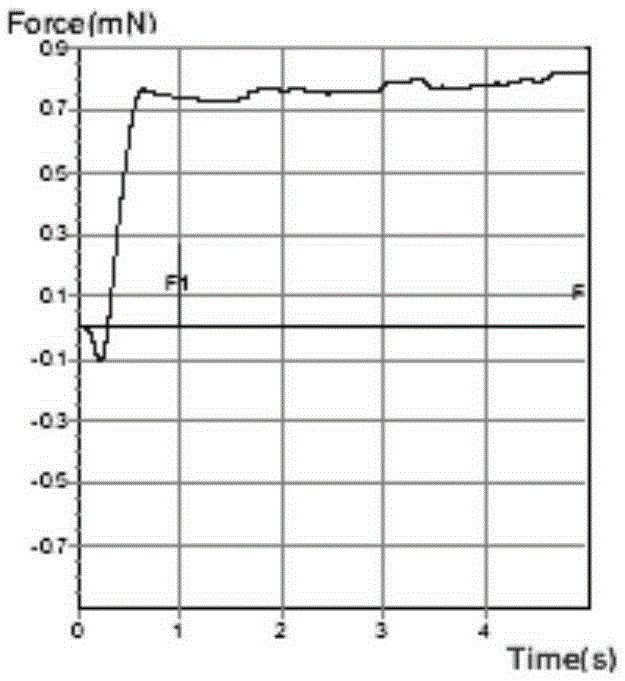

[0040] The lead-free solder test results of zinc-nickel-ni...

Embodiment 3

[0042] The processing technology for improving the performance of lead-free soldering of zinc-nickel-nickel strips. The production process of zinc-nickel-nickel strips is: casting→face milling→rough rolling→edge trimming→intermediate annealing→degreasing and cleaning→intermediate rolling→intermediate annealing→degreasing and cleaning→ Finished product rolling→finished product annealing→stretch bending straightening→finished product cleaning→strip warehousing; the finished product is rolled with a processing rate of 35%; the finished product is rolled with a roll with a surface roughness Ra=0.2μm; the finished product is annealed in an annealing furnace Carry out, the temperature is set at 490°C, and the gas atmosphere in the annealing furnace is 75%H 2 +25%N 2 , and heat treatment at this temperature for 10 hours, and the finished product is cleaned with an acid solution of H 2 SO 4 , the acid concentration is 6%.

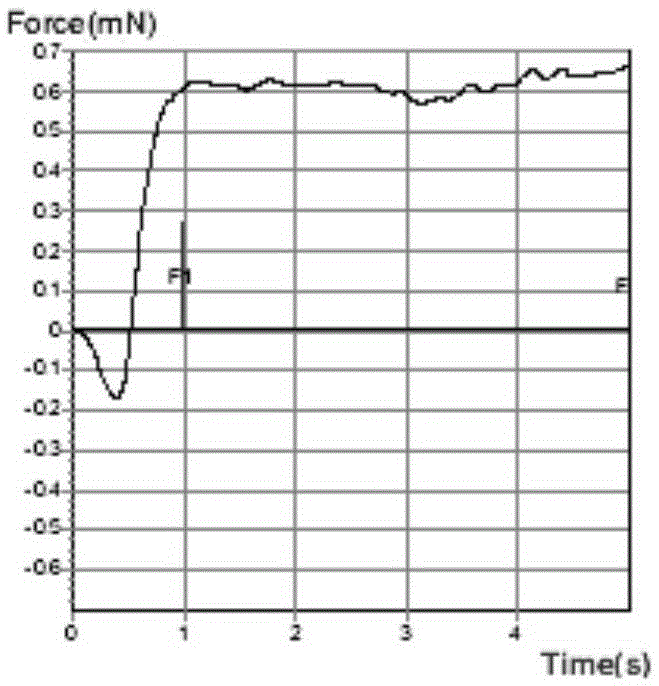

[0043] For the test results of lead-free solder on zinc-ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com