High-strength nickel silver alloy

A kind of zinc-white copper, high-strength technology, applied in the field of zinc-white copper alloy and high-strength zinc-white copper alloy, can solve the problems of unsatisfactory alloy strength, high cost and high price of zinc-white copper, and achieve good cold and hot processing performance. , the cost of raw materials is reduced, the effect of high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with embodiment the present invention is described in further detail.

[0013] The process route of this embodiment is: batching → continuous casting → stretching → annealing → pickling → stretching → finished product → (or finished product annealing) → packaging and storage.

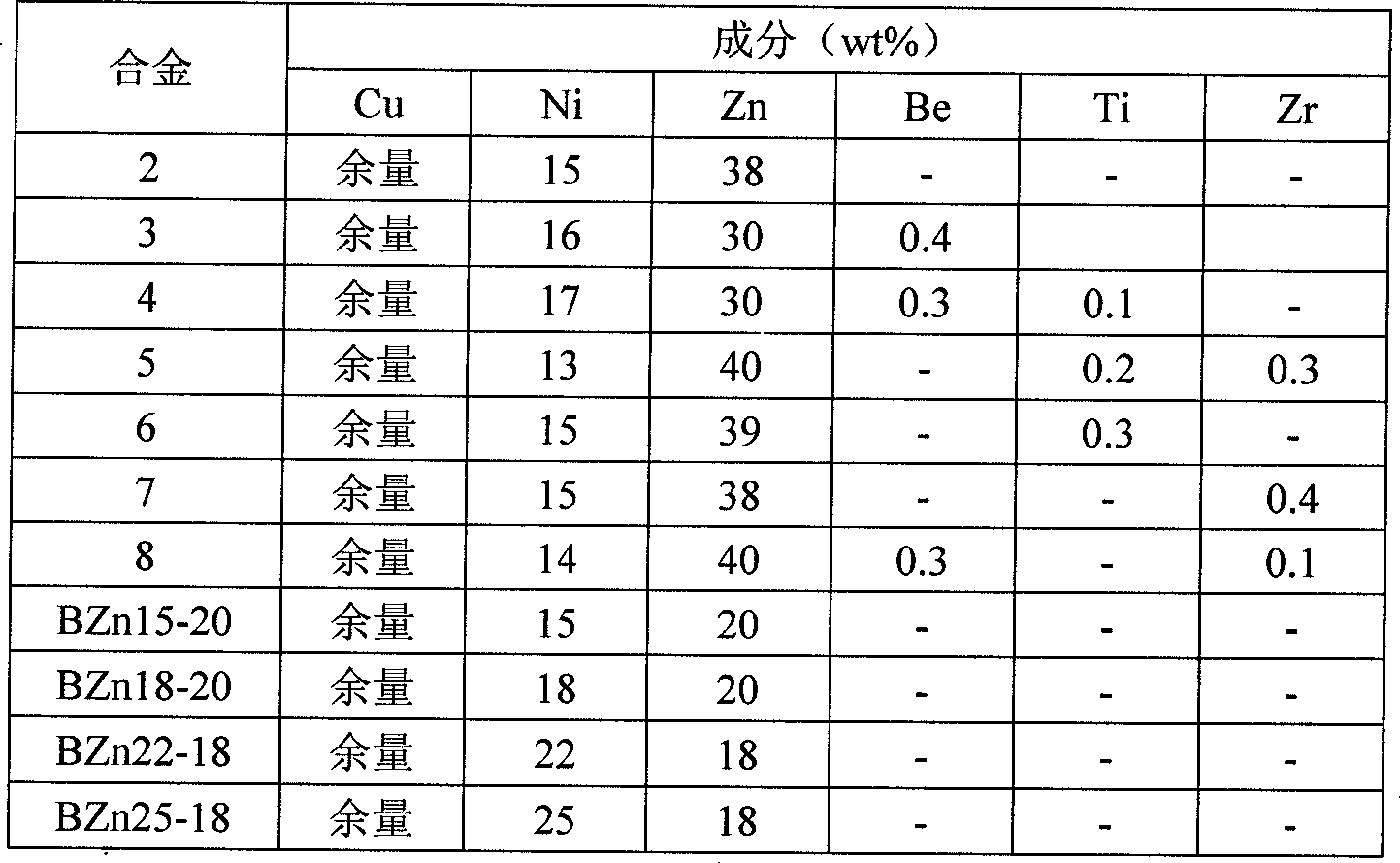

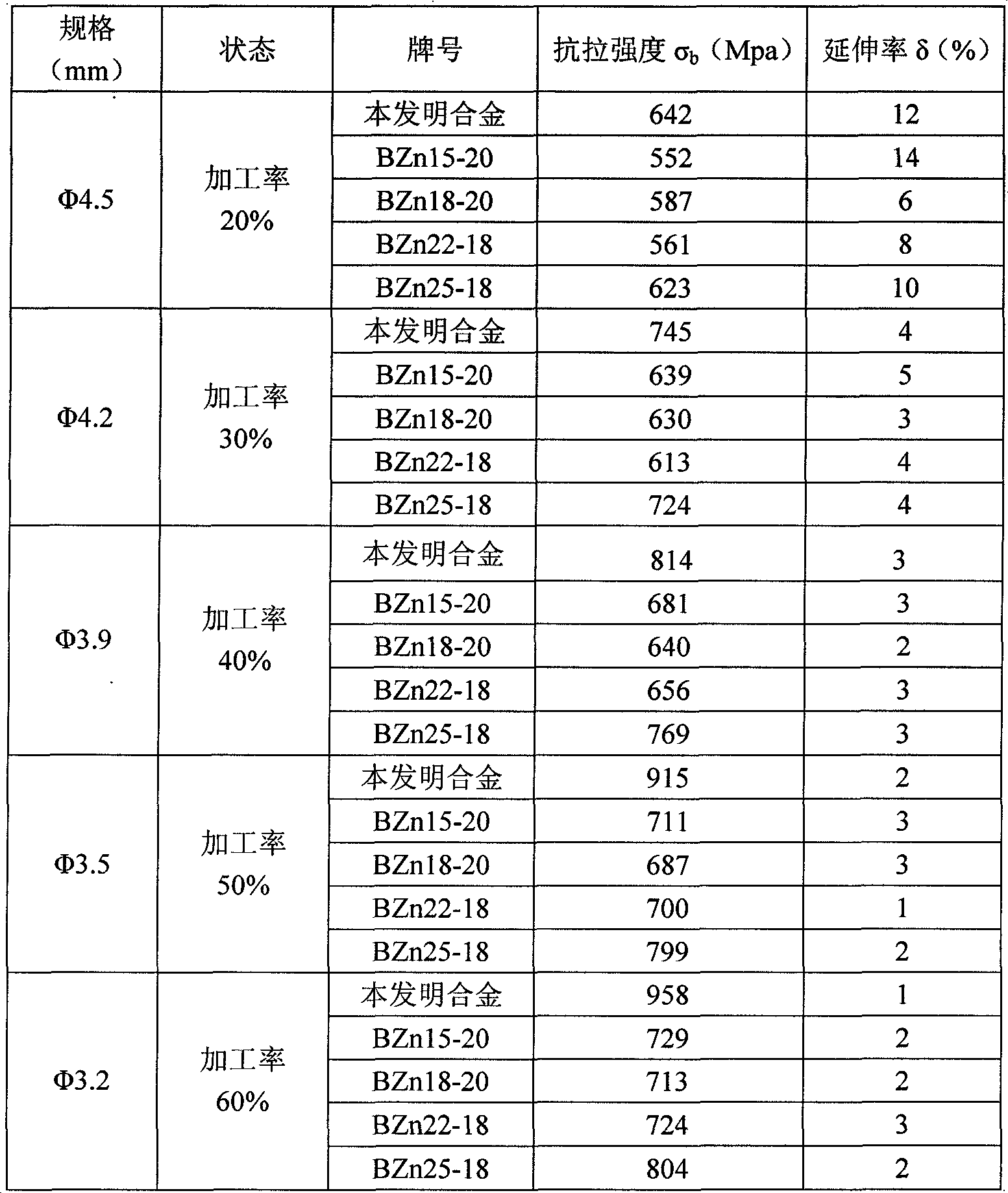

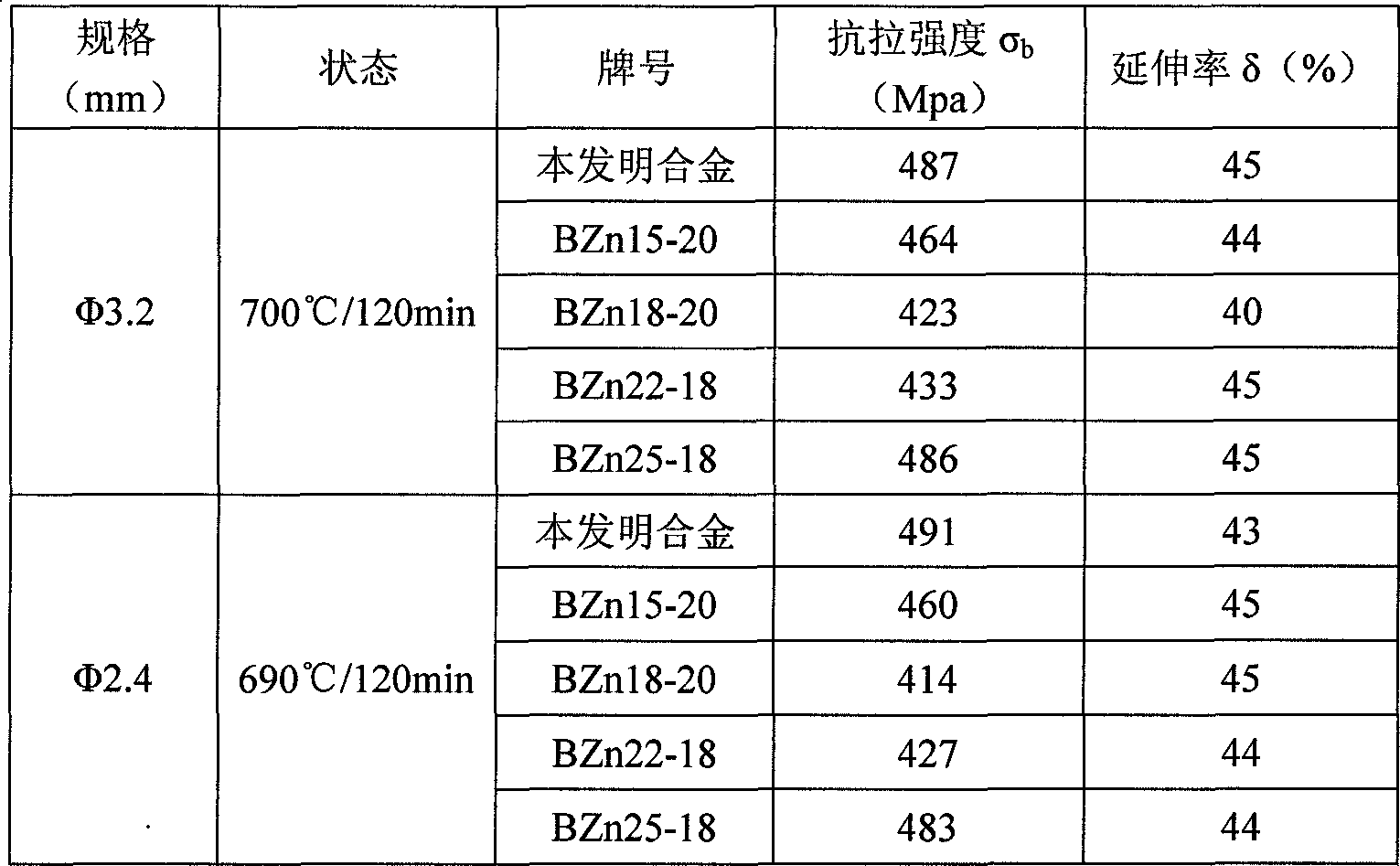

[0014] 1. Invention alloy composition (wt%):

[0015] Ni: 15%, Zn38%, Ti: 0.4%, Zr: 0.1%, Cu: balance

[0016] 2. Alloy melting process

[0017] Raw materials: electrolytic copper, electrolytic nickel, zinc ingot, Cu-6% Ti master alloy, Cu-5% Zr master alloy

[0018] Technical conditions and parameters: continuous casting slab specification: Φ12mm, melting temperature: 1300-1400℃, covering agent: dry charcoal.

[0019] Feeding sequence: electrolytic copper, electrolytic nickel → adding zinc after melting → adding intermediate alloy → pouring into a 300kg holding furnace for heat preservation after melting → the temperature in the holding furnace reaches above 1200°C, sampl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com