Welding method for relay contact reed assembly

A welding method and relay technology, applied in the direction of relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve problems such as whitening of the surface of reed components, high contact resistance, and burnt surface of reeds, so as to ensure the quality of welding core and increase heat dissipation effect, the effect of reducing the amount of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

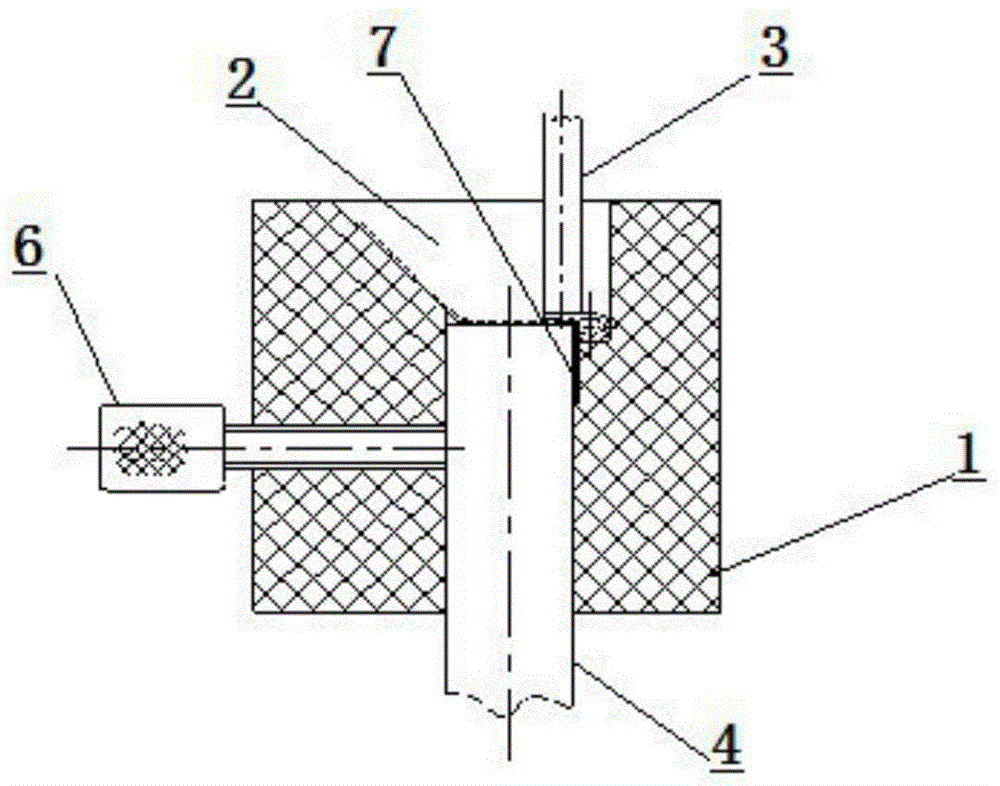

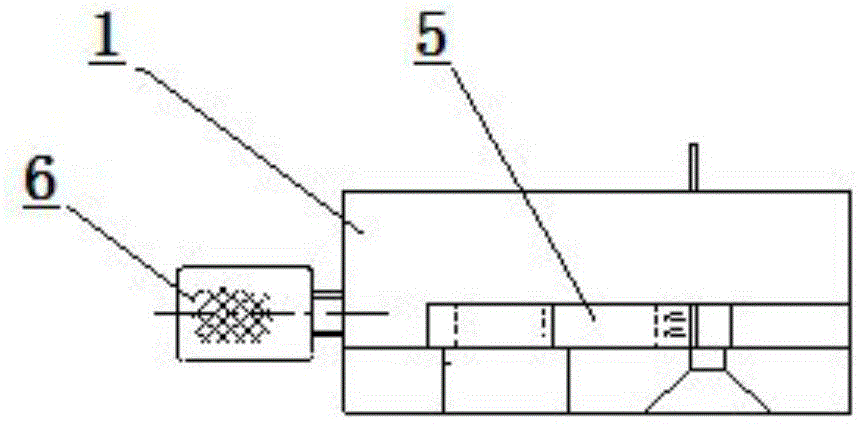

[0040] This embodiment discloses a welding method for a relay contact reed assembly, including equipment: a positioning fixture 1, an upper electrode assembly 3, a lower electrode assembly 4, and a welding contact reed assembly 5, wherein:

[0041] like figure 1 and figure 2 As shown, the positioning fixture 1 has a vertical electrode hole for installing the lower electrode assembly 4, and the lower electrode assembly 4 is fixed in the vertical electrode hole of the positioning fixture 1 through a lock nut 6, and the positioning fixture 1 has a limit groove 2;

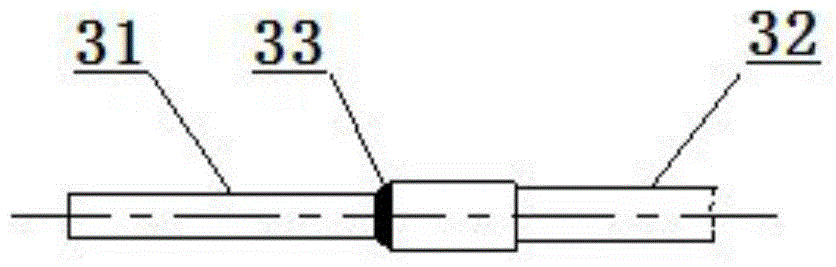

[0042] like Figure 5 , Image 6 and Figure 7 As shown, the contact reed assembly 5 includes a contact reed 51 and a welding wrap angle 52, the left end of the contact reed 51 has a terminal 53, and the right end of the welding wrap angle 52 has a seat plate terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com