Process for manufacturing power semiconductor module chip with high reliability and high power

A power semiconductor and manufacturing process technology, which is applied in the manufacturing process of high-reliability and high-voltage power semiconductor module chips, can solve problems such as high requirements for curing conditions, poor adhesion and stress, and easy deliquescence of PI glue, so as to improve the recognition degree and anti-counterfeiting ability, high cost performance, and the effect of preventing electron migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The description of the present invention is only a preferred embodiment of the invention, and is not intended to limit the invention. Any modification, equivalent replacement and improvement made within the spirit and principle of the invention should be included in the Within the scope of protection of the present invention.

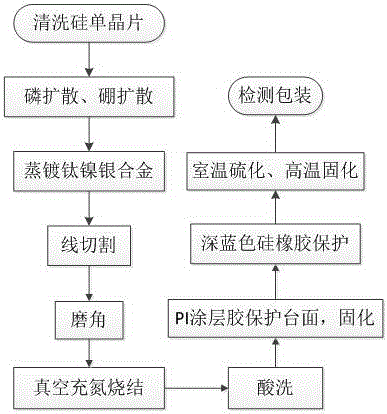

[0023] The present invention proposes a manufacturing process for a high-reliability high-voltage power semiconductor module chip, and the process flow chart is as follows figure 1 shown, including the following steps:

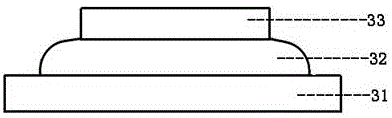

[0024] Step 1. After cleaning the silicon single wafer, perform phosphorus diffusion and boron diffusion, and then vapor-deposit a titanium-nickel-silver alloy layer on both sides of the silicon chip to effectively reduce the forward voltage drop V of the chip. FM , thermal resistance and stress;

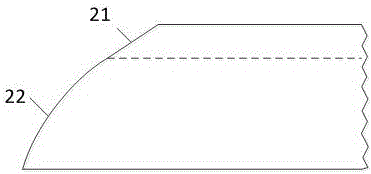

[0025] Step 2. Wire-cut the silicon wafer that has completed the diffusion process, and cut it into regular circular units with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com