Electrical plug connector as a fuel injector contact for vibration-resistant applications

A technology of electric plug connectors and contacts, which is applied in the direction of fuel injection devices, connections, parts of connection devices, etc., to achieve the effects of small contact resistance, reduced micro-motion, and stable contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

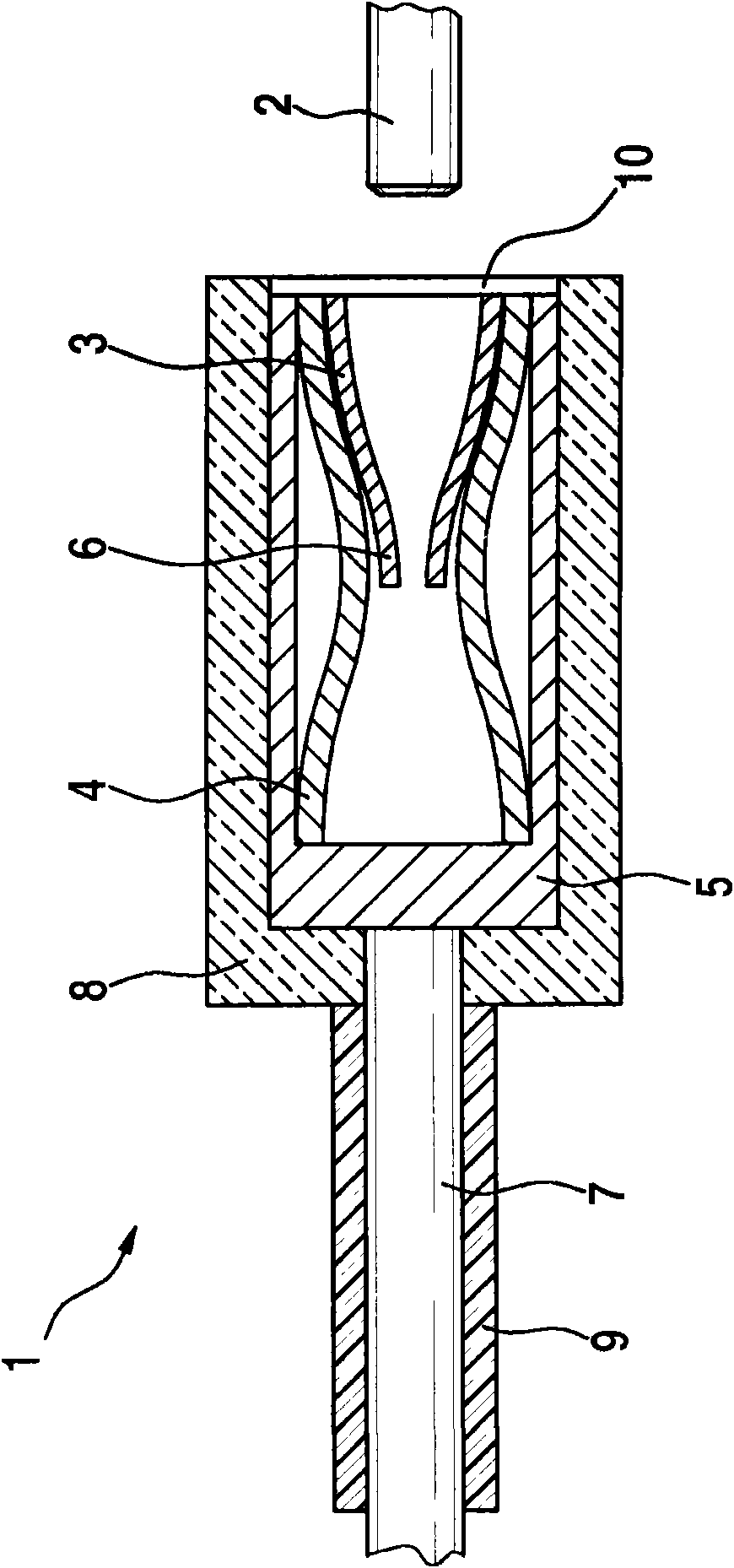

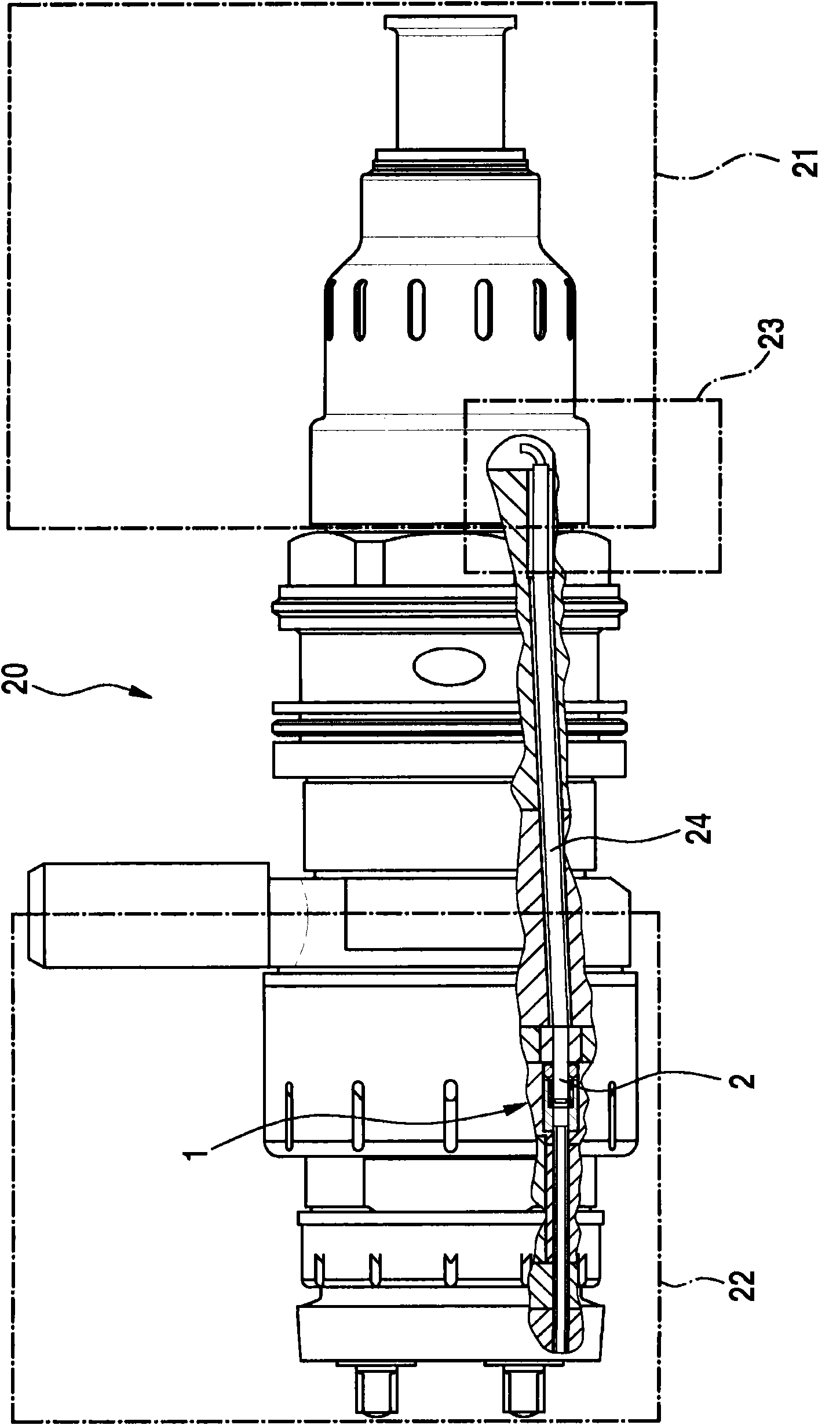

[0023] figure 1 The electrical connector 1 shown in is designed as a sleeve contact or a round contact for electrical contact with a pin plug 2 .

[0024] The electrical connector 1 comprises: a contact inner part 3 for electrical contact of the needle plug 2; an outer spring 4 enclosing the contact inner part 3; and a metal sleeve 5. The contact inner part 3 is made of nickel-nickel copper, preferably N18 (Wieland trade name), and in the shown embodiment is a longitudinally grooved circular sleeve with a plurality of inwardly directed contact fingers. (sheet) 6, and can be formed, for example, by a rolled sheet made of zinc-nickel-nickel copper. The contact interior part 3 has no surface coating, in particular no gold, silver or tin coating. The contact inner part 3 is clamped in an outer spring 4 made of stainless spring steel (for example 1.4310 with a strength of 1500 MPa). The outer spring 4 is installed in a metal sleeve 5 made of brass, for example, and clamped there...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com