A kind of dyeing method and product of ultra-high modulus polyethylene fiber

A technology of polyethylene fiber and dyeing method, which is applied in the direction of dyeing method, textiles and papermaking, etc., can solve the problems of complex process, poor heat resistance of UHMWPE, high equipment cost, etc. Infiltrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

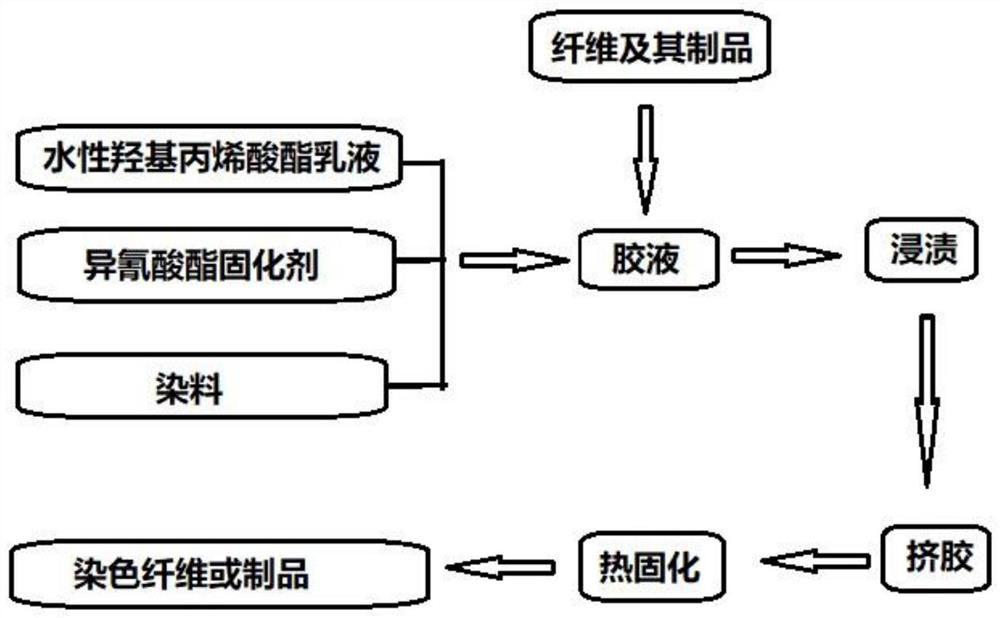

[0040] A kind of dyeing method of ultrahigh modulus polyethylene fiber adopts the method of chemical bonding, and concrete steps are as follows:

[0041] (1) 100 grams of water-based hydroxyacrylate resin emulsion (hydroxyl content 3.3wt%, solid content 42wt%) containing cetyl acrylate 5 grams, 0.1 gram of reactive brilliant blue KN-R type reactive dye, 25 grams of Bayer 2655 Add the isocyanate curing agent into the reaction bottle, stir at 700 rpm for 10 minutes at high speed to form a dyed glue, and add it to the glue tank of the gluing machine;

[0042] (2) After dipping and extruding the ultra-high modulus polyethylene fiber or its products through a gluing machine, heat it to 80 degrees Celsius to cure for 20 minutes, and the coloring of the ultra-high modulus polyethylene fiber or its products is completed.

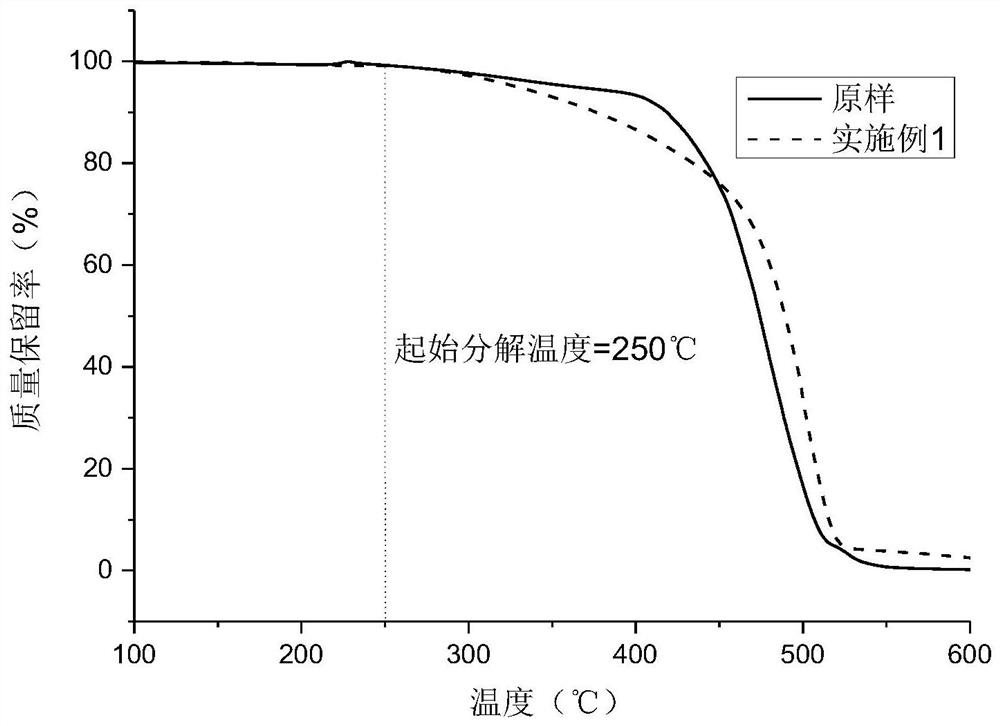

[0043] The fiber color is blue after dyeing. The tensile breaking strength of 200 ultra-high modulus polyethylene fibers without dyeing is 44.5N, the tensile break...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com