A kind of acf conductive adhesive tape and its preparation process and application

A conductive adhesive tape and preparation technology, which is applied in the direction of conductive adhesives, adhesives, and recording carriers used by machines, can solve the problems of thermal damage on the back of the card body, large gaps between contact points, and low production efficiency, and achieve significant economic benefits. Benefits and social benefits, fast and efficient module packaging operations, and the effect of improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

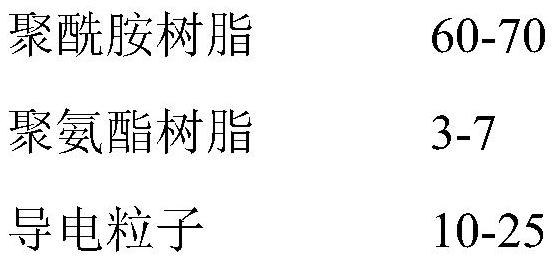

[0035] This embodiment provides an ACF conductive adhesive tape, which includes a release layer and an adhesive film layer; the release layer in this embodiment is a release paper, and the material of the release paper is double-sided silicone oil glassine paper. The upper surface of the release layer is coated with an adhesive film layer, the thickness of the adhesive film layer is 40 μm, and the adhesive film includes the following components by weight:

[0036]

[0037] The conductive particles are spherical silver-plated copper particles, and the particle diameter of the conductive particles is 20-30 μm.

[0038] Thermally conductive fillers are calcium carbonate and talcum powder.

[0039] Thixotropic agents are fumed silica, clay and talc.

[0040] The preparation technology of ACF conductive adhesive tape comprises the steps:

[0041] S1. Blend the polyamide resin, polyurethane resin and conductive particles in a twin-screw extruder, the extrusion temperature is 14...

Embodiment 2

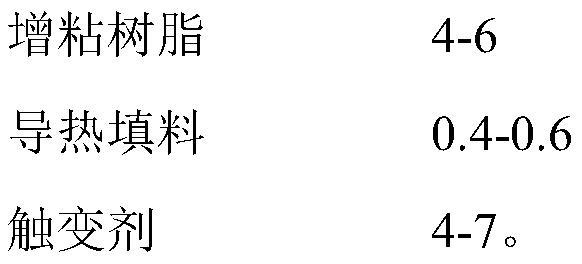

[0045] This embodiment provides an ACF conductive adhesive tape, which includes a release layer and an adhesive film layer; the release layer in this embodiment is a release paper, and the material of the release paper is double-sided silicone oil glassine paper. The upper surface of the release layer is coated with an adhesive film layer, the thickness of the adhesive film layer is 60 μm, and the adhesive film includes the following components by weight:

[0046]

[0047] The conductive particles are spherical silver-coated aluminum particles with a particle diameter of 30-50 μm, and the silver-coated aluminum particles have excellent oxidation resistance and electrical conductivity.

[0048] The thermally conductive filler is quartz.

[0049] The thixotropic agent is rosin resin and petroleum resin.

[0050]The preparation technology of ACF conductive adhesive tape comprises the steps:

[0051] S1. Blend the polyamide resin, polyurethane resin and conductive particles i...

Embodiment 3

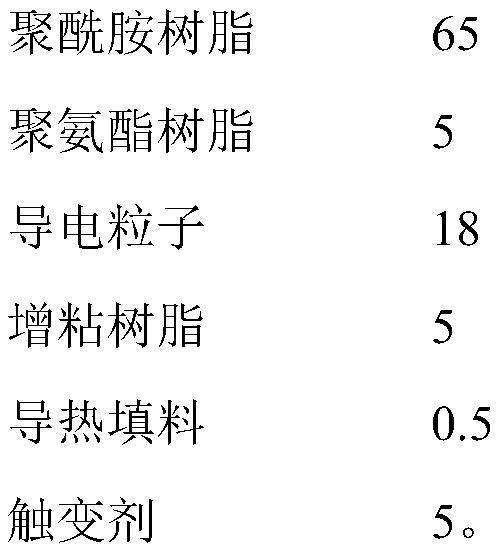

[0055] This embodiment provides an ACF conductive adhesive tape, which includes a release layer and an adhesive film layer; the release layer in this embodiment is a release paper, and the material of the release paper is double-sided silicone oil glassine paper. The upper surface of the release layer is coated with an adhesive film layer, the thickness of the adhesive film layer is 50 μm, and the adhesive film includes the following components by weight:

[0056]

[0057]

[0058] The conductive particles are spherical gold-nickel-coated styrene particles, and the particle diameter of the conductive particles is 30-40 μm.

[0059] The thermally conductive filler is clay.

[0060] The thixotropic agent is paraffin.

[0061] The preparation technology of ACF conductive adhesive tape comprises the steps:

[0062] S1. Perform twin-screw extrusion blending of polyamide resin, polyurethane resin, tackifying resin, thermally conductive filler, and thixotropic agent. The extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com