Ion flame detection circuit and method

A detection circuit and ion flame technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of low flame detection sensitivity, poor grounding of the burner head, and reduced contact area of the negative electrode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

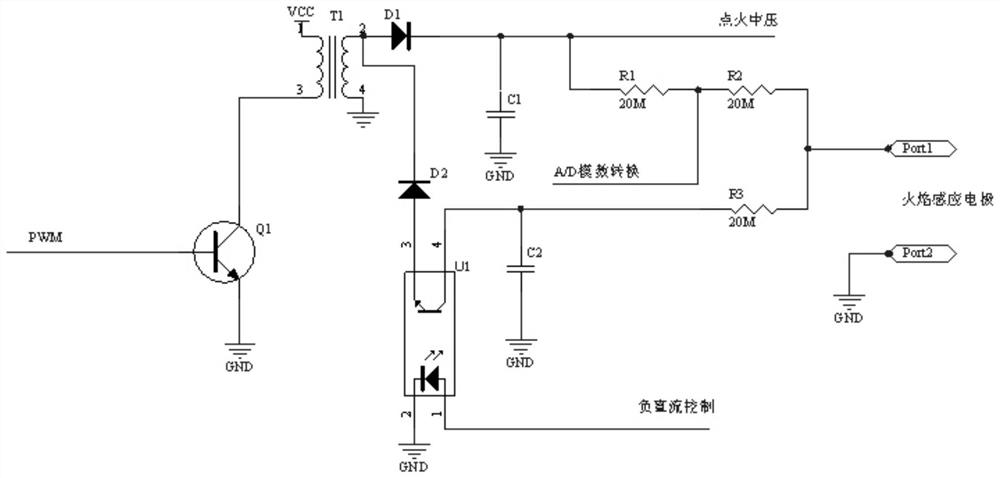

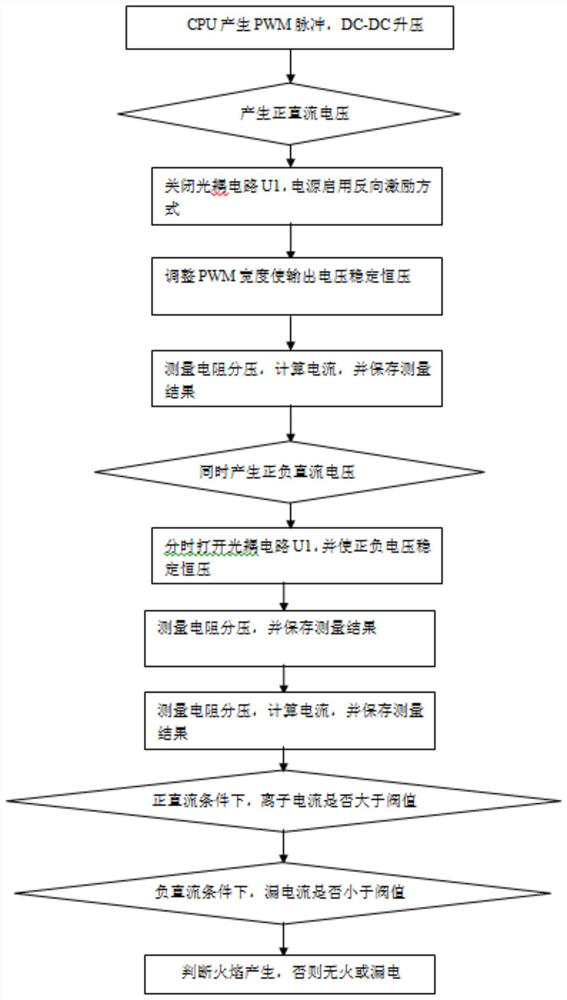

[0024] An ion flame detection circuit, reference Figure 1 to Figure 2 , including single-chip microcomputer, DC-DC unit, positive DC analog switch, negative DC analog switch, positive DC sampling unit, negative DC sampling unit, optocoupler circuit U1, detection circuit and CPU, CPU generates PWM pulse width modulation signal, DC -The DC unit changes the voltage and current output of the PWM pulse width through the positive DC analog switch and the negative DC analog switch; the single-chip microcomputer measures the flame equivalent resistance indirectly through the resistance divider to measure the ion current. The positive and negative DC-DC unit adopts the flyback switching power supply method to generate positive voltage. When the voltage is ignited, it is the input voltage of the ignition high voltage, and the high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com