Field effect diode

A field effect diode and electrode technology, applied in the field of diodes, can solve the problems of poor rectification performance, inability to prepare homogeneous PN junction diodes, and poor interface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the objectives, technical solutions, and advantages of the present invention clearer, the following further describes the present invention in detail through specific embodiments with reference to the accompanying drawings.

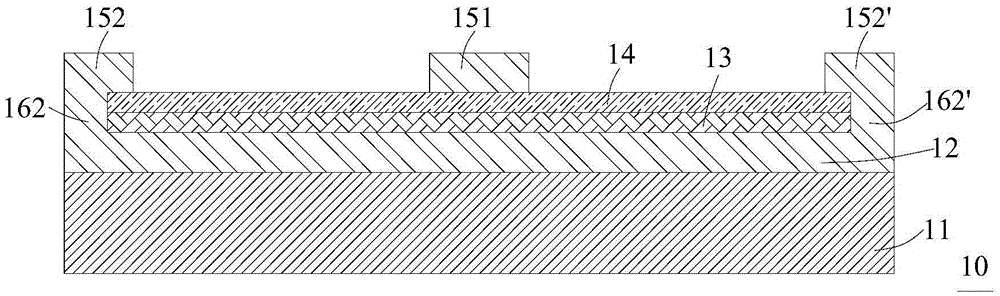

[0029] figure 1 It is a cross-sectional view of the field effect diode according to the first embodiment of the present invention. Such as figure 1 As shown, the field effect diode 10 includes a glass substrate 11, an indium tin oxide conductive layer 12, an aluminum oxide insulating layer 13, a zinc oxide channel layer 14, and a first electrode located on the zinc oxide channel layer 14, from bottom to top. 151 and second electrodes 152, 152' arranged on opposite sides of the first electrode 151, and conductive pillars 162, 162' contacting two opposite sides of the aluminum oxide insulating layer 13 and the zinc oxide channel layer 14. The second electrodes 152, 152' are electrically connected to the indium tin oxide conductive layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com