Preparation method of nickel-silver alloy steel strip for battery case

A technology of battery shell and alloy steel, which is applied in the direction of battery pack components, circuits, electrical components, etc. It can solve problems affecting the corrosion resistance of accessories, conductivity and weldability, and affect the internal resistance of the battery shell, so as to enhance corrosion resistance properties, reducing internal resistance, and strong antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

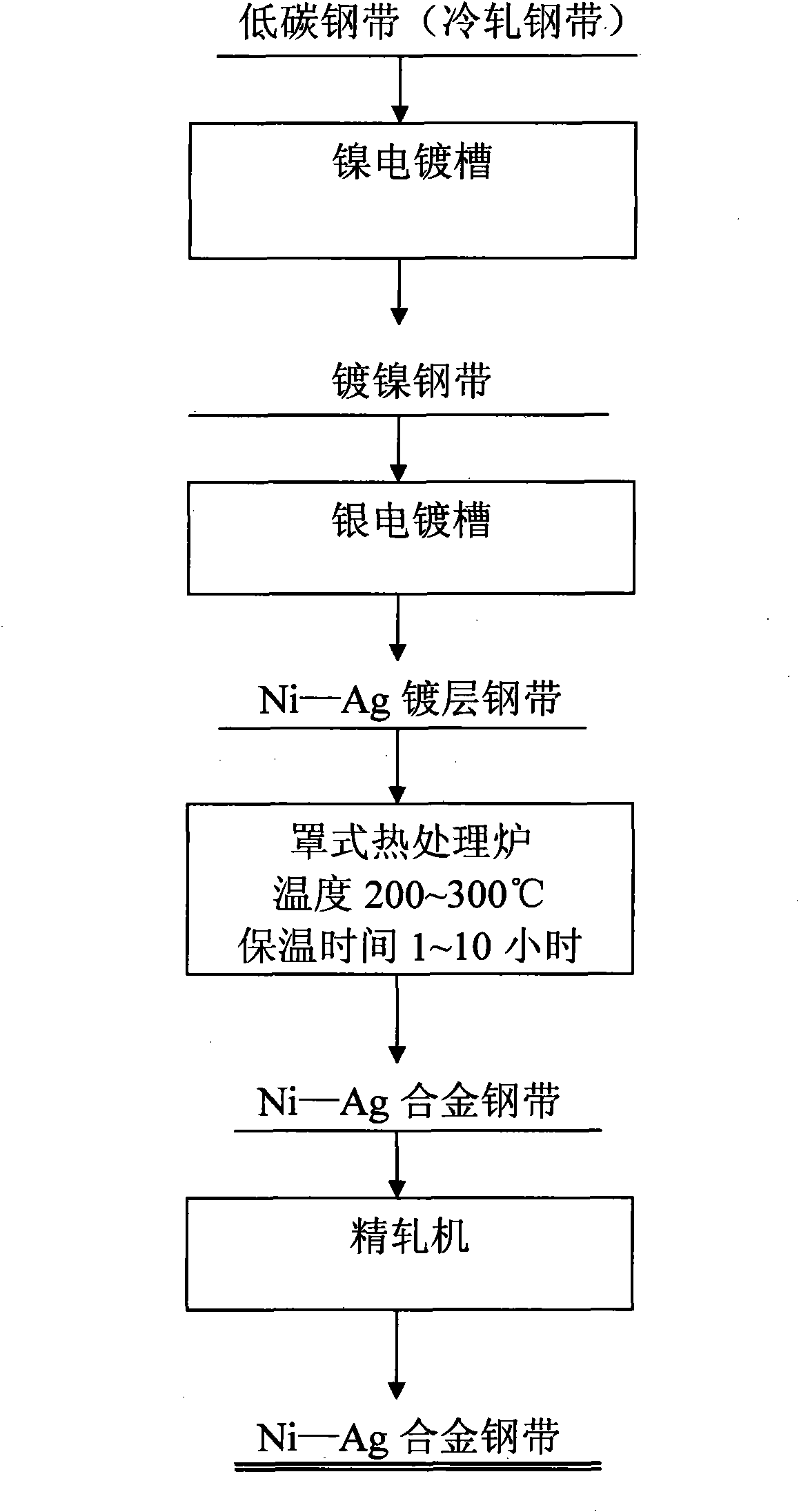

[0023] The cold-rolled steel strip (low carbon steel strip) of Baosteel (produced by Baoshan Iron and Steel Company, brand BDCK) with a thickness of 0.25mm is selected as the electroplating substrate, and nickel plating is carried out after chemical degreasing, electrolytic degreasing and pickling (all traditional processes). → Silver plating → Heat treatment → Finish rolling.

[0024] Nickel plated

[0025] Nickel sulfate 280g / L, nickel chloride 40g / L, boric acid 45g / L, saccharin 0.5g / L, pH 4.0, temperature 50℃, current density 5A / dm 2 , the plating time is 1 minute, and the plating thickness is 1 μm.

[0026] silver

[0027] Silver nitrate 45g / L, Ammonium thiosulfate 250g / L, SL-80 additive (developed by Guangzhou Electrical Apparatus Institute) 10ml / L, auxiliary agent (developed by Guangzhou Electrical Apparatus Institute) 0.4ml / L, pH value 5.5, temperature 35℃, current density 0.8A / dm 2 , the plating time is 1 minute, and the plating thickness is 0.1 μm.

[0028] heat ...

example 2

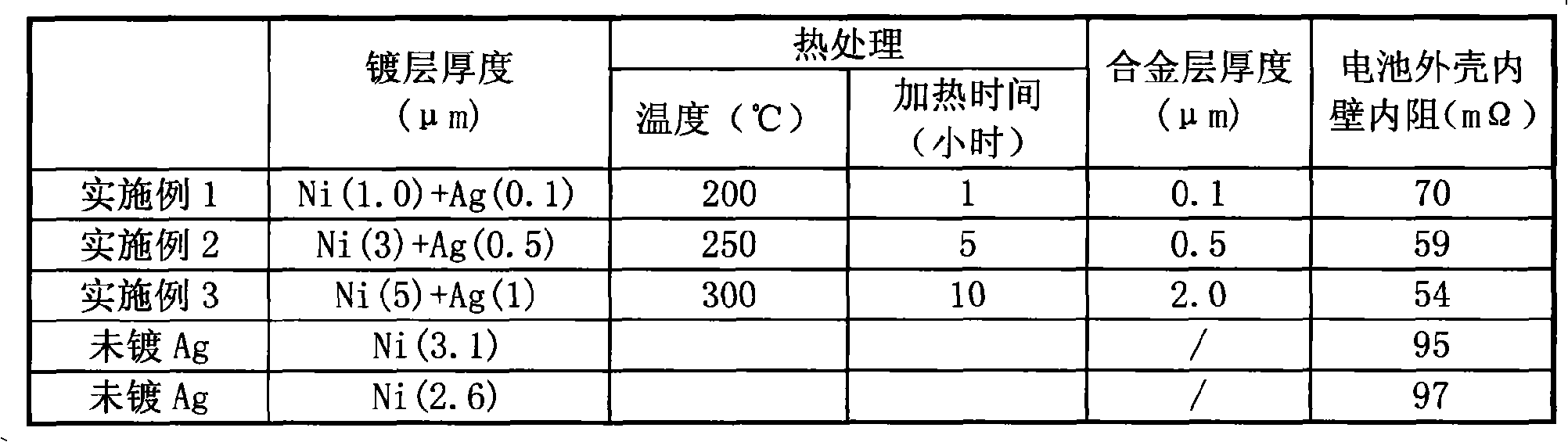

[0035] The thickness of the nickel coating is 3 μm, and the plating time is 3 minutes; the thickness of the silver coating is 0.5 μm, and the plating time is 2.5 minutes; the steel strip with nickel-silver coating is sent to a bell furnace for heat treatment, the temperature is 250 ° C, and the holding time is 5 hours. A nickel-silver alloy layer with a thickness of 0.5 μm is formed between it and the silver layer, and the rest is the same as that of Example 1.

example 3

[0037] The thickness of the nickel coating is 5 μm, and the plating time is 5 minutes; the thickness of the silver coating is 1 μm, and the plating time is 5 minutes; the steel strip with nickel-silver coating is sent to the bell furnace for heat treatment, the temperature is 300 ° C, and the holding time is 10 hours. A nickel-silver alloy layer with a thickness of 2 μm was formed between the silver layers, and the rest were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com