Steel structure part surface protective coating and preparation method thereof

A technology for protective coatings and structural parts, applied in the field of protective coatings on the surface of steel structural parts and its preparation, can solve the problems of short anti-corrosion life, high porosity, limited coating thickness, etc., to improve corrosion resistance and prolong service life , the effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

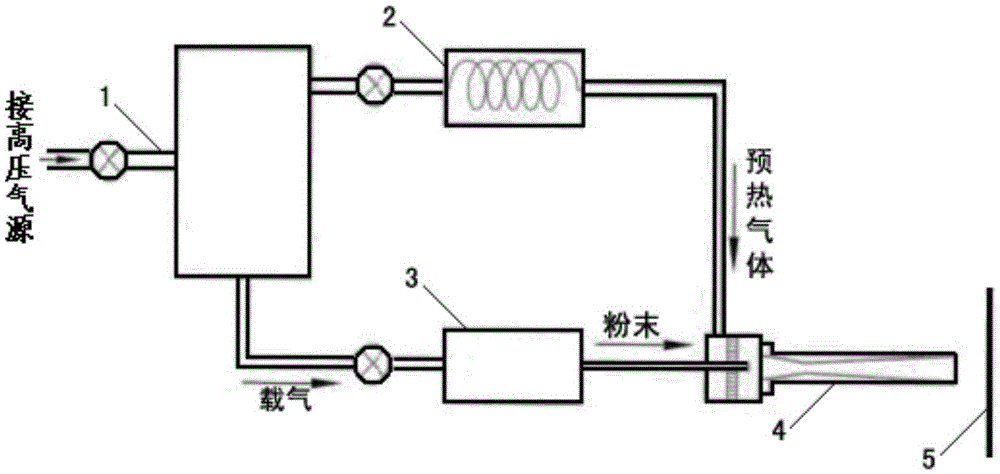

Method used

Image

Examples

Embodiment 1

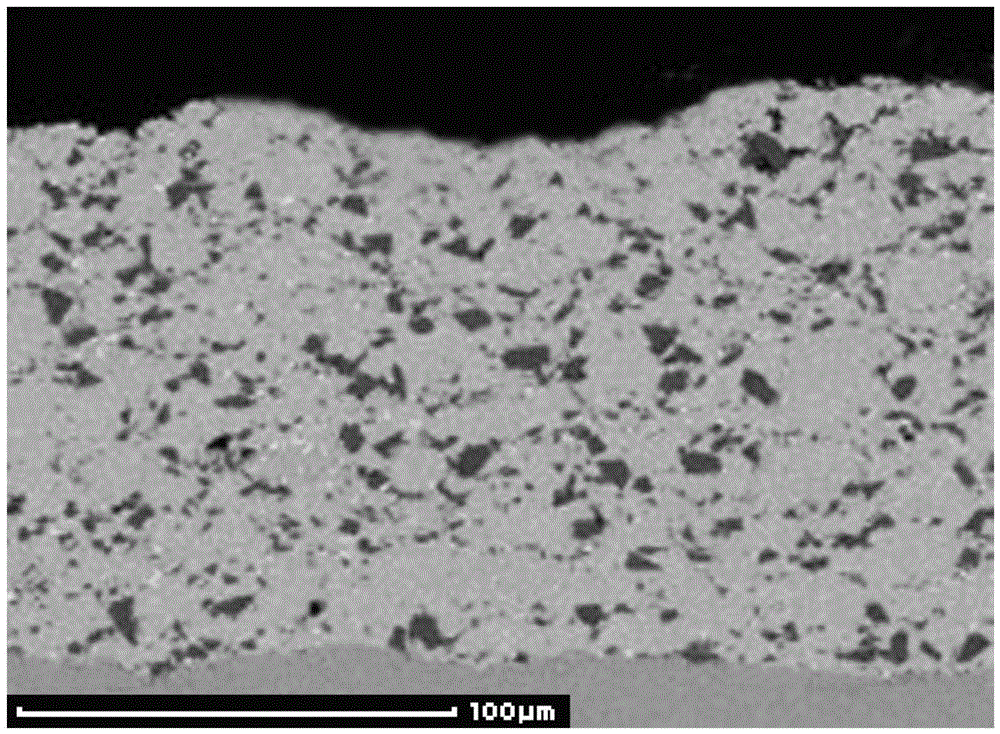

[0038] The surface of the light steel alloy of the high-voltage transmission tower is mechanically sandblasted to make it look metallic, and then within 8 hours, the Zn / Al / Mg alloy powder is directly sprayed on the light steel alloy of the high-voltage transmission tower by using a high-speed airflow On the surface of structural parts, the compressed gas is air, by controlling the spraying parameters: spraying distance 25mm, gas pressure 3.5MPa, gas temperature 600°C, air flow rate 35g / s, spraying time 20min / m 2 , Zn / Al / Mg alloy powder is deposited on the surface of the light steel alloy to obtain a uniformly distributed protective coating, the thickness of the coating is 120 microns, and its structure is as follows figure 2 As shown, the coating is firmly combined with the steel structure and can be used as a long-term protective coating for the steel structure.

Embodiment 2

[0040]The surface of the light steel alloy of the high-voltage transmission tower is mechanically sandblasted to make it have a metallic color, and then within 8 hours, the Zn / Al / Mg alloy powder is directly sprayed on the light steel alloy of the high-voltage transmission tower by using a high-speed airflow On the surface of structural parts, the compressed gas is air, by controlling the spraying parameters: spraying distance 40mm, gas pressure 4.0MPa, gas temperature 700°C, air flow rate 40g / s, spraying time 30min / m 2 , Zn / Al / Mg alloy powder is deposited on the surface of the light steel alloy to obtain a uniformly distributed protective coating, the thickness of the coating is 180 microns, and it is firmly combined with the steel structure, which can be used as the steel structure Long-lasting protective coating.

Embodiment 3

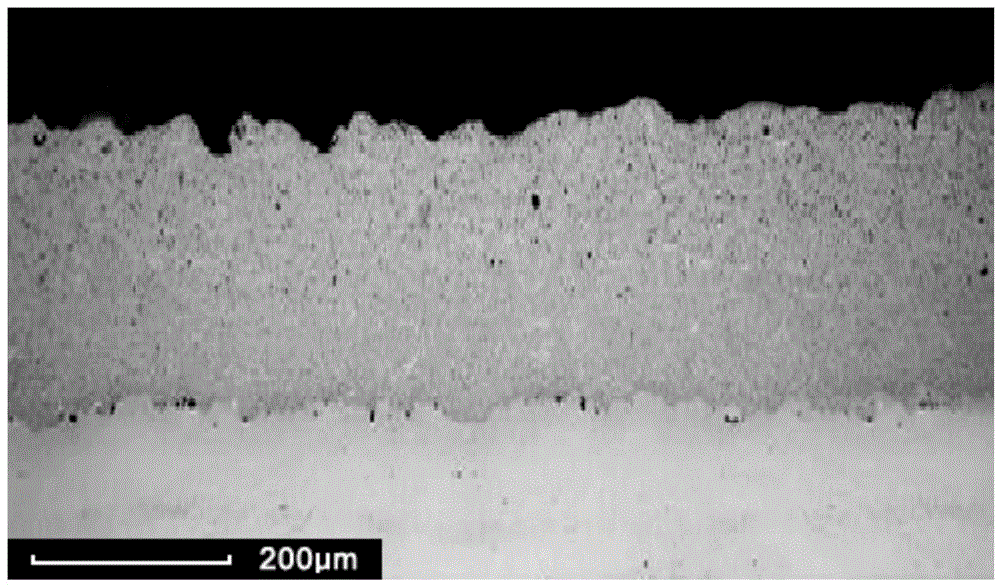

[0042] The surface of the light steel alloy of the high-voltage transmission tower is mechanically sandblasted to make it have a metallic color, and then within 8 hours, the Zn / Al / Mg alloy powder is directly sprayed on the light steel alloy of the high-voltage transmission tower by using a high-speed airflow On the surface of structural parts, the compressed gas is air, by controlling the spraying parameters: spraying distance 45mm, gas pressure 4.5MPa, gas temperature 800°C, air flow rate 45g / s, spraying time 45min / m 2 , Zn / Al / Mg alloy powder is deposited on the surface of the light steel alloy to obtain a uniformly distributed protective coating. The thickness of the coating is 260 microns, and its structure is as follows image 3 As shown, it is firmly combined with the steel structure and can be used as a long-term protective coating for the steel structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com