Composite flux suitable for magnesium-aluminum-series magnesium alloy, preparation method thereof and application thereof

A magnesium alloy and magnesium-aluminum technology, which is applied in the composite flux of magnesium-aluminum series magnesium alloy and its preparation field, can solve the problems of insignificant purification effect, single function, and environmental hazards, and achieve increased refinement effect and simple preparation process , Reduce the effect of floating burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0029] The third embodiment of the present invention provides an application of the above-mentioned composite flux suitable for magnesium-aluminum-series magnesium alloys in refining magnesium-aluminum-series magnesium alloys.

[0030] The fourth embodiment of the present invention provides a method for refining magnesium-aluminum-based magnesium alloys. The smelted magnesium-aluminum-based magnesium alloys are melted in a protective gas atmosphere, and the above-mentioned suitable for The composite flux of magnesium-aluminum series magnesium alloy is stirred until a mirror effect appears on the surface of the melt, and after standing still, the temperature is lowered to 680-720°C for pouring.

[0031] In some examples of this embodiment, the protective gas atmosphere is CO 2 with SF 6 Gas atmosphere of mixed gas.

[0032] In some examples of this embodiment, the magnesium-aluminum alloy is melted at a temperature of 720-725°C.

[0033] In some examples of this embodiment, ...

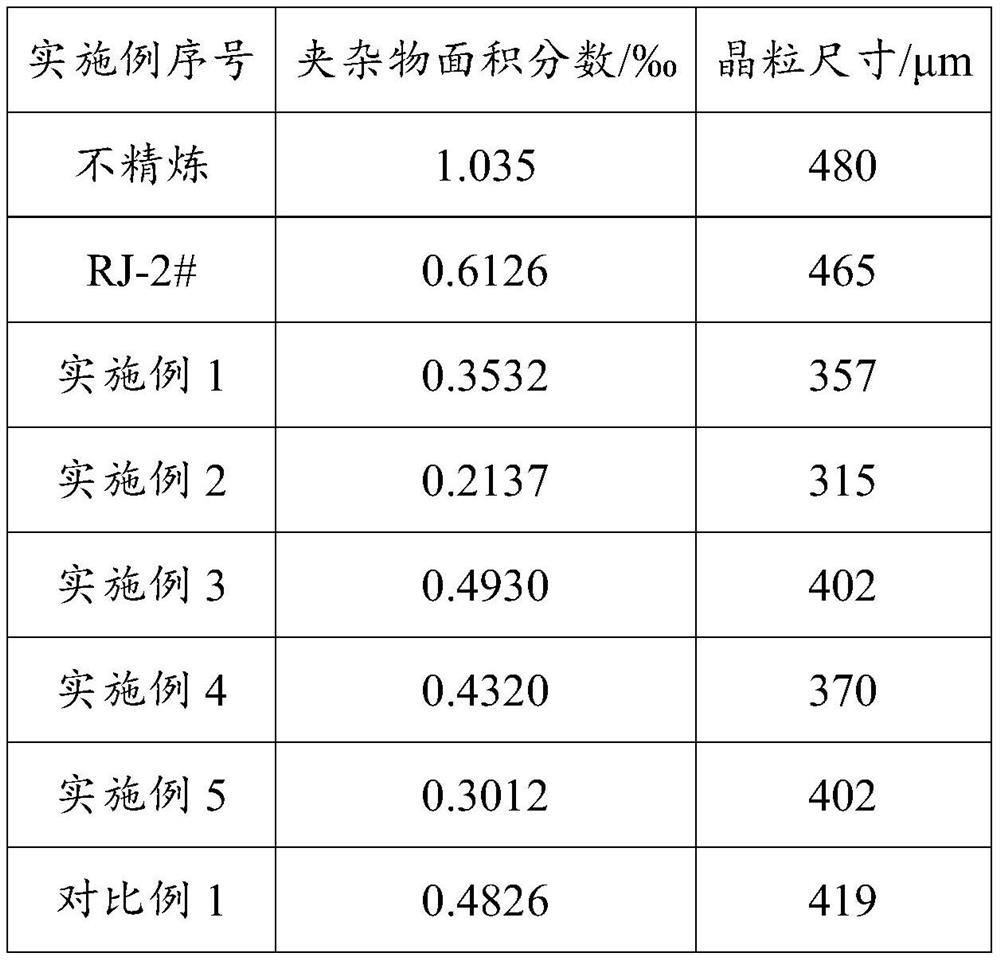

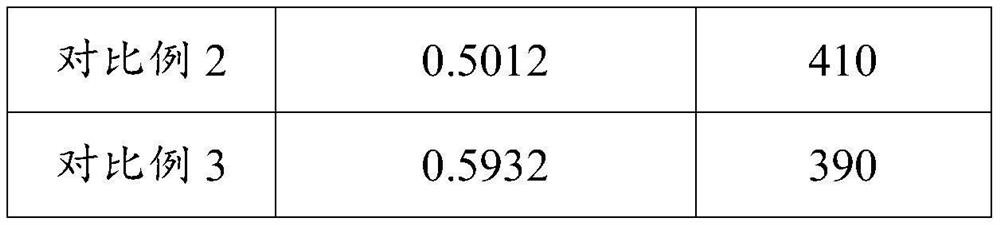

Embodiment 1

[0037] A magnesium alloy composite flux consisting of the following components by mass fraction: MgCl: 30%, KCl: 20%, NaCl: 5%, BaCl 2 : 5%, CaCl 2 : 5%, CaF 2 : 10%, C powder: 1%, Ti powder: 5%, mixed rare earth oxide: 20%; the mixed rare earth oxide is cerium oxide (CeO 2 ), yttrium oxide (Y 2 o 3 ), scandium oxide (Sc 2 o 3 ) are formed by mixing according to the mass ratio of 3:3:4.

[0038] The preparation method of the magnesium alloy composite flux is as follows: stir the magnesium chloride, potassium chloride, sodium chloride, calcium chloride, barium chloride, and calcium fluoride with a good weighing ratio, pour them into the crystallizer, and carry out mechanical crushing. Grind to make powder, and finally put it into a ball mill and mix it with C powder, Ti powder and mixed rare earth oxide according to the ratio of ball milling. The ball-to-material ratio is 20:1, and the ball milling time is 20 minutes to obtain a magnesium alloy composite flux, which is se...

Embodiment 2

[0041] A magnesium alloy composite flux consisting of the following components by mass fraction: MgCl: 35%, KCl: 25%, NaCl: 4%, BaCl 2 : 6%, CaCl 2 : 6%, CaF 2 : 10%, C powder: 2%, Ti powder: 2%, mixed rare earth oxide: 10%; the mixed rare earth oxide is cerium oxide (CeO 2 ), yttrium oxide (Y 2 o 3 ), scandium oxide (Sc 2 o 3 ) are formed by mixing according to the mass ratio of 3:3:4.

[0042] The preparation method of the magnesium alloy composite flux is as follows: stir the magnesium chloride, potassium chloride, sodium chloride, calcium chloride, barium chloride, and calcium fluoride with a good weight ratio, pour them into the crystallizer, and carry out mechanical crushing. Grind to make powder, and finally put it into a ball mill and mix it with C powder, Ti powder and mixed rare earth oxide according to the ratio of ball milling. The ball-to-material ratio is 20:1, and the ball milling time is 30 minutes to obtain a magnesium alloy composite flux, which is seal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com