Flux for aluminum and aluminum alloy melt refining and preparation method of flux

An aluminum alloy melt and flux technology, which is applied in the field of refining flux with slag and sodium removal functions and its preparation, can solve the problems of unsuitable control, impurity elements in aluminum alloy melt, life-threatening and other problems, and achieves the promotion of dissolution and elimination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

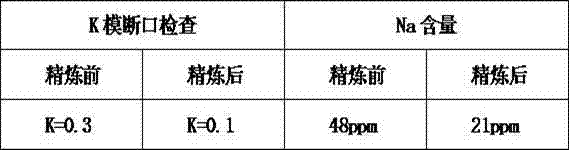

Embodiment 1

[0037] A kind of flux used for refining aluminum and aluminum alloy melt, the mass percentage is composed of Na 3 AlF 6 1%, K 3 AlF 6 4%, MgCl 2 50%, KCl 37%, K 2 TiF 6 7%, graphite powder 1%. After preliminarily mixing the above raw materials, place them in a graphite crucible and heat up to 700°C for melting. Use tungsten tools to mechanically stir the molten flux for 10 minutes, keep it warm for 30 minutes, and perform secondary mechanical stirring for 10 minutes. The cooled and solidified bulk flux is broken and screened into 0.1-1mm particles, and finally the qualified products are dried and packaged.

Embodiment 2

[0039] A kind of flux used for refining aluminum and aluminum alloy melt, the mass percentage is composed of Na 3 AlF 6 28%, K 3 AlF 6 12%, AlF 3 46.9%, KCl 10%, K 2 TiF 6 3%, graphite powder 0.1%. After preliminarily mixing the above raw materials, place them in a graphite crucible and heat up to 900°C for melting. Use tungsten tools to mechanically stir the molten flux for 5 minutes, keep it warm for 20 minutes, and perform secondary mechanical stirring for 20 minutes. The cooled and solidified bulk flux is broken and screened into 0.1-1mm particles, and finally the qualified products are dried and packaged.

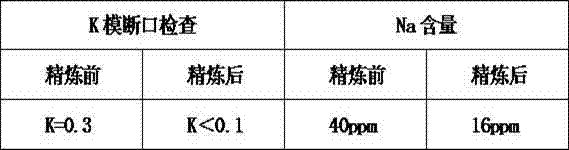

Embodiment 3

[0041] A kind of flux used for refining aluminum and aluminum alloy melt, the mass percentage is composed of Na 3 AlF 6 11%, K 3 AlF 6 18%, MgCl 2 10%, AlF 3 10%, KCl 40%, K 2 TiF 6 8%, graphite powder 3%. After preliminarily mixing the above raw materials, place them in a graphite crucible and heat up to 800°C for melting. Use tungsten tools to mechanically stir the molten flux for 20 minutes, keep it warm for 40 minutes, and perform secondary mechanical stirring for 5 minutes. The cooled and solidified bulk flux is broken and screened into 0.1-1mm particles, and finally the qualified products are dried and packaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com