SnS2-CNTs composite material and preparation method thereof, as well as preparation method of composite anode material

A composite material and dispersion technology, applied in the field of materials, can solve problems such as poor conductivity of elemental sulfur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

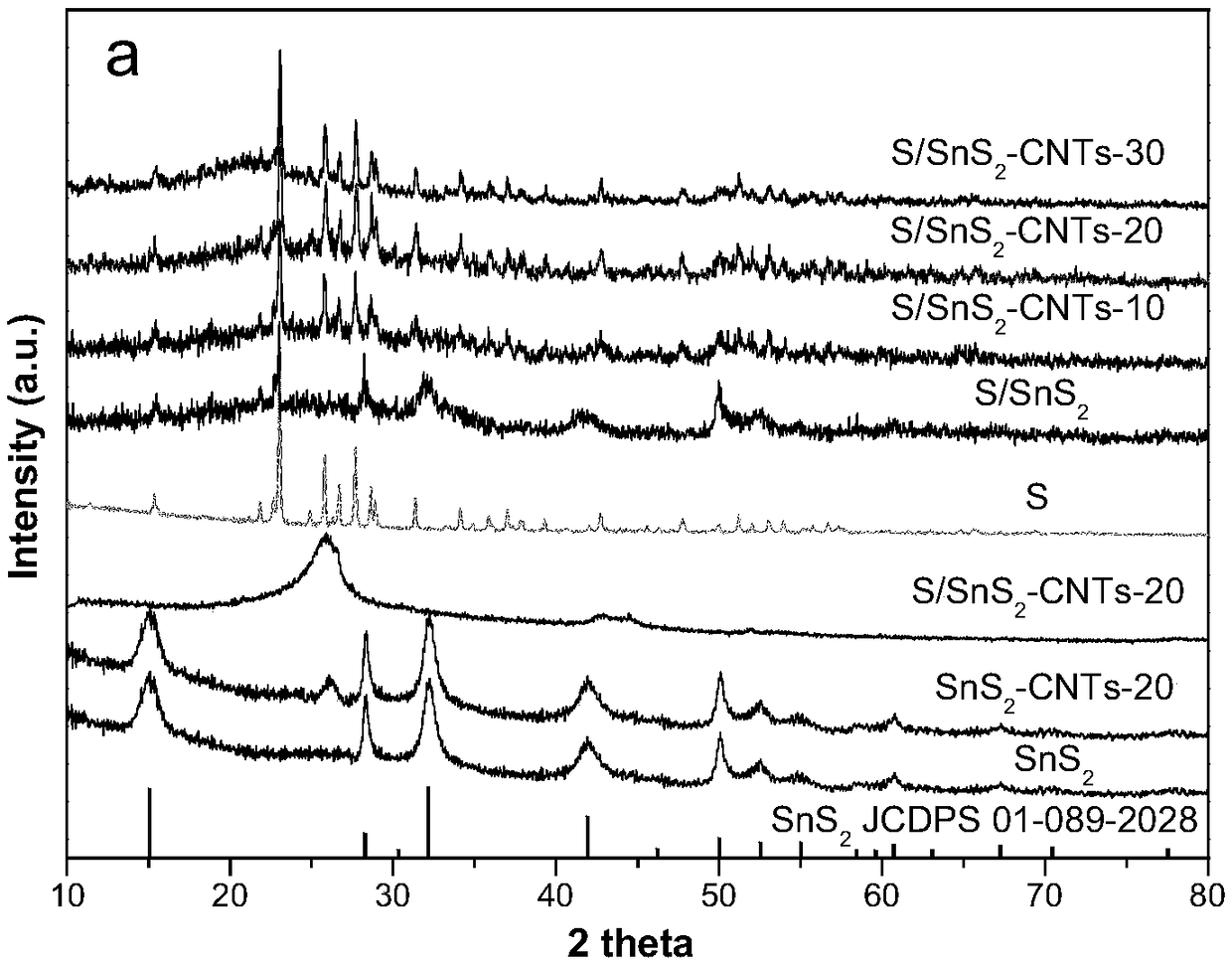

[0023] A kind of SnS provided by the embodiment of the present invention 2 -The preparation method of CNTs composite material, comprises the following steps:

[0024] S1. Add tin tetrachloride pentahydrate into the uniformly dispersed CNTs dispersion, and stir evenly to obtain the first solution.

[0025] Further, the homogeneous dispersion of the CNTs dispersion is carried out by ultrasonic dispersion for 3.5-4.5 hours.

[0026] In other optional embodiments of the present invention, to uniformly disperse the above-mentioned CNTs dispersion liquid may also choose to adopt other applicable dispersion methods in the art.

[0027] Further, in this embodiment, the above-mentioned CNTs dispersion liquid can be selected to be self-made or obtained through commercial purchase.

[0028] Optionally, CNTs are prepared by CVD.

[0029] Concretely, the quartz boat that will fill appropriate amount of catalyst is put into tube furnace, under 50sccmAr atmosphere, temperature is increase...

Embodiment 1

[0056] A preparation method for preparing a composite positive electrode material provided in this embodiment comprises the following steps:

[0057] CNTs were prepared by CVD method. The specific process is as follows: put a quartz boat filled with an appropriate amount of self-made catalyst into a tube furnace, and set the temperature at 10°C. min -1 The heating rate was raised to 800°C, and then 40sccmH 2 , reduce the catalyst at constant temperature for 60min; then lower the temperature to 700°C under 30sccmAr atmosphere, and pass a mixed gas (25sccm C 2 h 2 and 225sccmAr), 60min to grow CNTs. Finally, under the 50sccmAr atmosphere, it is naturally lowered to room temperature, taken out and put into a round bottom flask, and an appropriate amount of concentrated HNO is added. 3 , after ultrasonic dispersion, it was condensed and refluxed at 80°C for 5 hours, filtered and washed until neutral, and dried overnight at 60°C to obtain CNTs.

[0058] Disperse CNTs in 50ml ...

Embodiment 2

[0061] A preparation method for preparing a composite positive electrode material provided in this embodiment comprises the following steps:

[0062] CNTs were prepared by CVD method. The specific process is as follows: put a quartz boat filled with an appropriate amount of self-made catalyst into a tube furnace, and set the temperature at 10°C. min -1 The heating rate was raised to 800°C, and then 40sccmH 2 , reduce the catalyst at constant temperature for 60min; then lower the temperature to 700°C under 30sccmAr atmosphere, and pass a mixed gas (25sccm C 2 h 2 and 225sccmAr), 60min to grow CNTs. Finally, under the 50sccmAr atmosphere, it is naturally lowered to room temperature, taken out and put into a round bottom flask, and an appropriate amount of concentrated HNO is added. 3 , after ultrasonic dispersion, it was condensed and refluxed at 80°C for 5 hours, filtered and washed until neutral, and dried overnight at 60°C to obtain CNTs.

[0063] Disperse CNTs in 50ml ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com