Standard substance for TC11 titanium alloy photoelectric spectral analysis and preparation method thereof

A spectral analysis and standard material technology, applied in the field of analysis and detection, can solve the problems of no effective distribution points and ineffective detection of alloy elements, etc., and achieve good uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

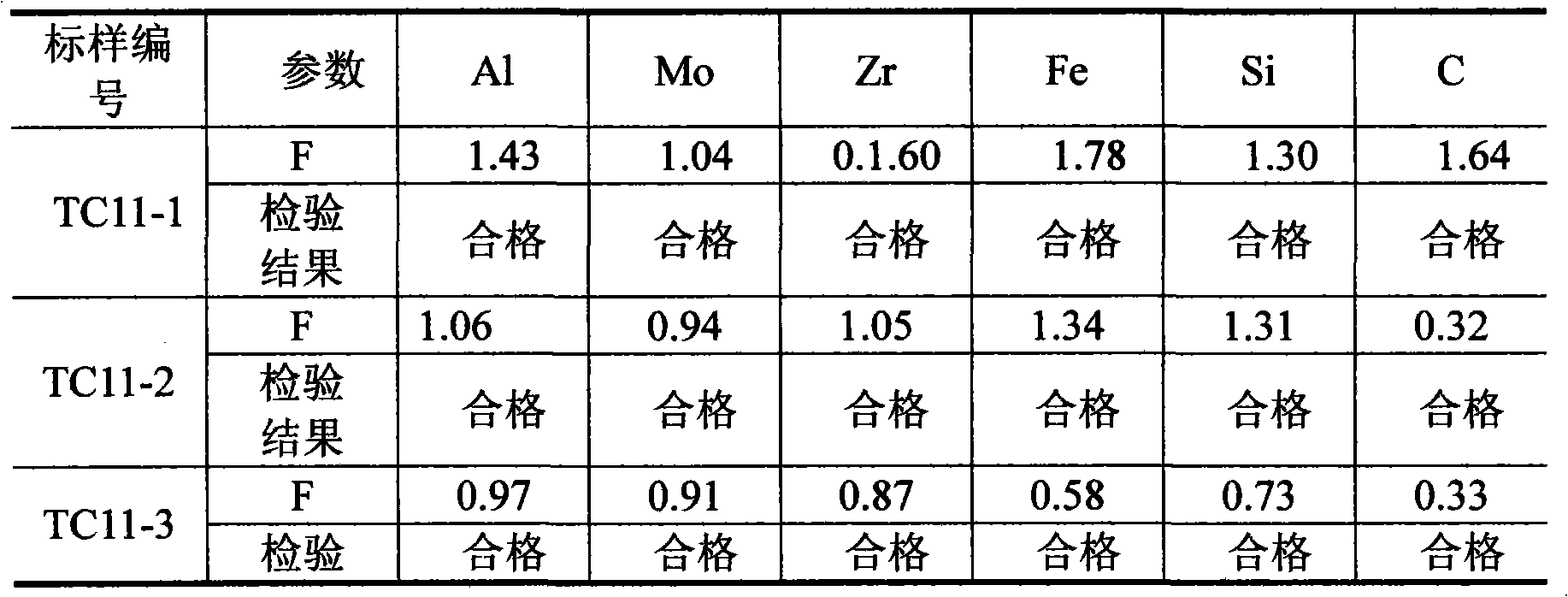

Embodiment 1

[0067] According to the mass percentage, weigh 4.53% Al, 2.20% Mo, 0.59% Zr, 0.15% Si, 0.15% Fe, 0.021% C, and the balance is sponge titanium, the sum of the mass percentages of each component is 100%. After mixing Al, Mo, Zr, Si, Fe and C on the aluminum foil, wrap it into a strip-shaped alloy bag; press the electrode with a vertical horizontal pressing machine, and weigh the electrode in the previous step according to the number of electrodes to be pressed. The titanium sponge is divided into several equal parts, and each part of the titanium sponge is divided into two parts on average. First, one part is added to the mold and distributed evenly along the length of the mold. Then, the alloy package is placed into the titanium sponge along the axial direction of the mold. A piece of titanium sponge is evenly spread on the upper end of the alloy bag, and the press is started to press the electrode. The size of the press is 1000 tons, and the alloy bag is wrapped with sponge ti...

Embodiment 2

[0069] According to the mass percentage, weigh 5.50% Al, 4.65% Mo, 2.41% Zr, 0.24% Si, 0.20% Fe, 0.041% C, and the balance is titanium sponge, the sum of the mass percentages of each component is 100%. After mixing Al, Mo, Zr, Si, Fe and C on the aluminum foil, wrap it into a strip-shaped alloy bag; press the electrode with a vertical horizontal pressing machine, and weigh the electrode in the previous step according to the number of electrodes to be pressed. The titanium sponge is divided into several equal parts, and each part of the titanium sponge is divided into two parts on average. First, one part is added to the mold and distributed evenly along the length of the mold. Then, the alloy package is placed into the titanium sponge along the axial direction of the mold. A piece of titanium sponge is evenly spread on the upper end of the alloy bag, and the press is started to press the electrode. The size of the press is 1000 tons, and the alloy bag is wrapped with sponge ti...

Embodiment 3

[0071] According to mass percentage, weigh 6.04% of Al, 3.26% of Mo, 1.51% of Zr, 0.23% of Si, 0.24% of Fe, 0.057% of C, and the balance is titanium sponge, the sum of the mass percentages of each component is 100%. After mixing Al, Mo, Zr, Si, Fe and C on the aluminum foil, wrap it into a strip-shaped alloy bag; press the electrode with a vertical horizontal pressing machine, and weigh the electrode in the previous step according to the number of electrodes to be pressed. The titanium sponge is divided into several equal parts, and each part of the titanium sponge is divided into two parts on average. First, one part is added to the mold and distributed evenly along the length of the mold. Then, the alloy package is placed into the titanium sponge along the axial direction of the mold. A piece of titanium sponge is evenly spread on the upper end of the alloy bag, and the press is started to press the electrode. The size of the press is 1000 tons, and the alloy bag is wrapped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com