Low-cost magnesium alloy with high room-temperature plastic deformation and preparation process thereof

A wrought magnesium alloy and preparation process technology, applied in the field of metal materials, can solve the problems of high primary and secondary plastic processing costs, poor room temperature plasticity of rolled sheets, poor thermoplastic processing properties, etc., and achieve good room temperature formability and good thermoplasticity. Processability, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1) Take pure Mg ingots, pure Zn ingots, pure Mn ingots and Mg-30Ca master alloy as raw materials, and mix according to the weight percentage of Mg-0.19Zn-0.34Ca-0.32Mn alloy composition (No. 1 in Table 1);

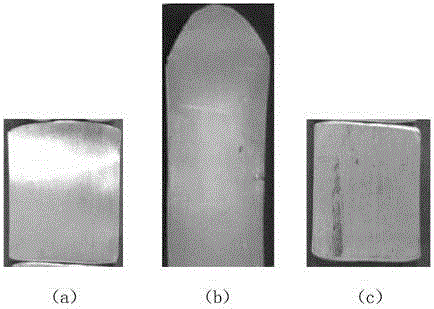

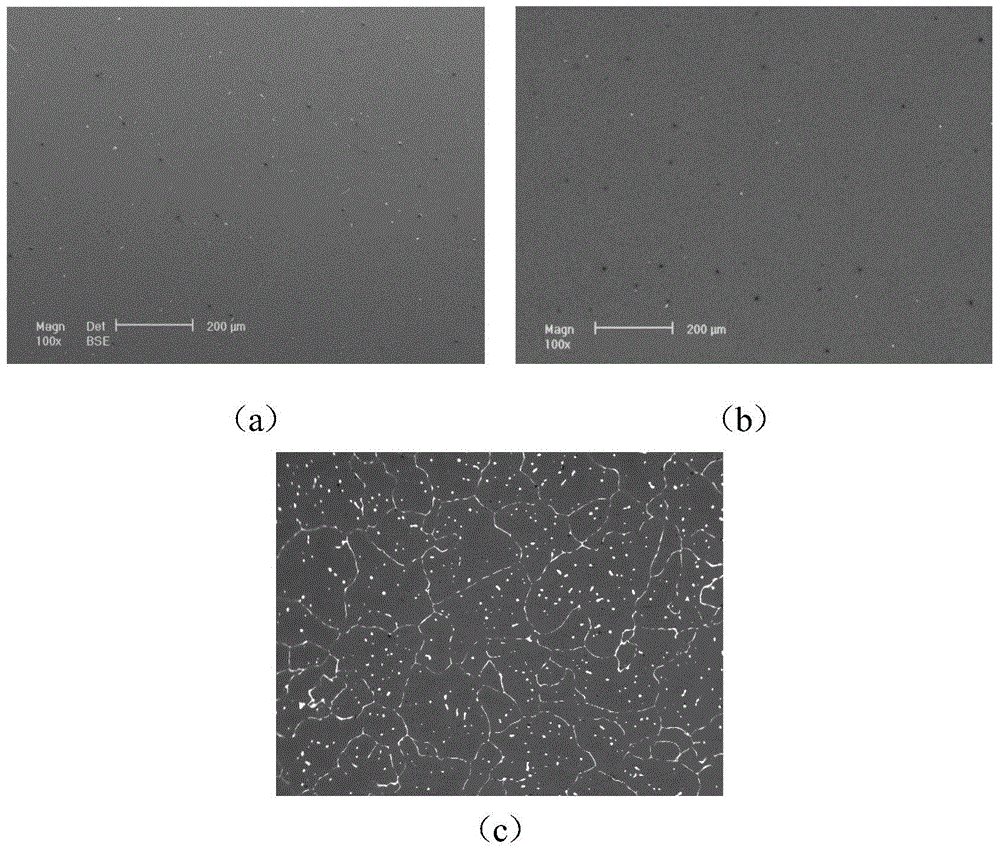

[0041] 2) Using metal mold gravity casting, Mg-Zn-Ca-(Mn) alloy is cast into an ingot of 150mm×200mm×200mm by conventional magnesium alloy melting; the number of second phases in the as-cast structure of the alloy is very small and the size is not Big as figure 1 (a) shown;

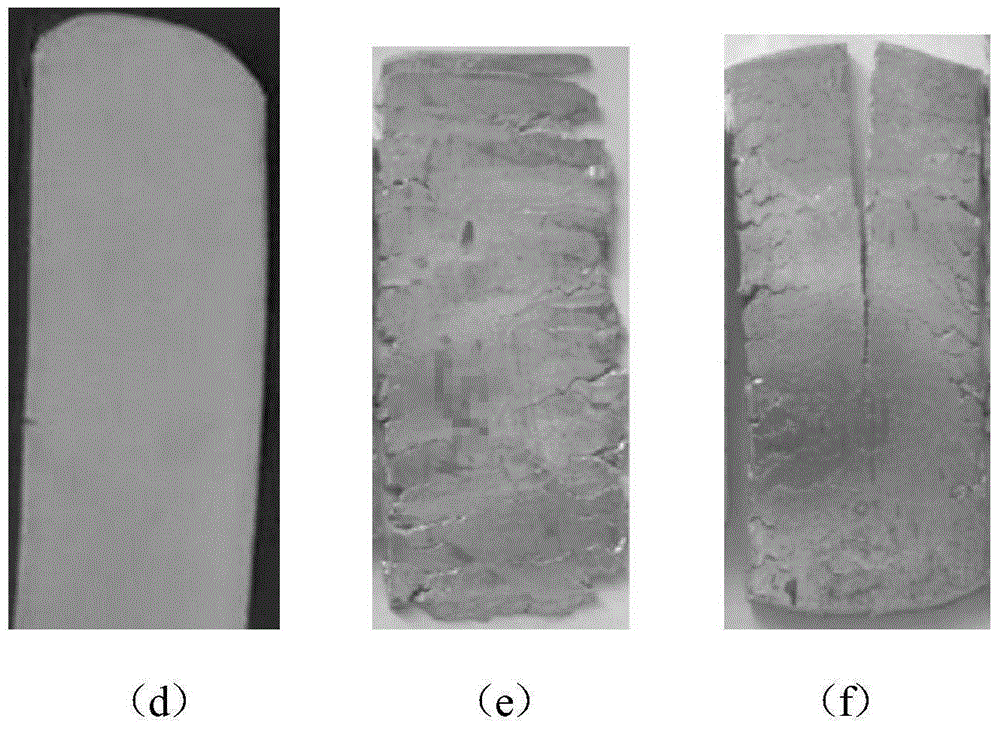

[0042] 3) After the ingot is kept at 430℃ for 10 hours and homogenized, the ingot is cut into 150mm×100mm×20mm billets and milled, and the milled billets are heated at 250°C for 2 hours before rolling; The preheating temperature is 300℃; the rolling deformation speed is 15m / min, and the reduction of each pass is 30-60% (the macro photo of the single pass 40% reduction of the plate is as figure 2 As shown in (a), it has no cracks and has good rolling performance). After each pass, return to the fur...

Embodiment 2

[0046] 1) Using pure Mg ingots, pure Zn ingots and pure Ca as raw materials, the ingredients are mixed according to the weight percentage of Mg-0.37Zn-0.13Ca alloy composition (No. 2 in Table 1);

[0047] 2) Using metal mold gravity casting, Mg-Zn-Ca alloy is cast into an ingot of 150mm×200mm×200mm by conventional magnesium alloy melting; the second phase in the as-cast structure of the alloy is very small and the size is not large;

[0048] 3) After the ingot is kept at 420°C for 15 hours for homogenization, the ingot is cut into 150mm×100mm×20mm billets and milled, and the milled billets are heated at 400°C for 2 hours before rolling; The temperature is room temperature; the rolling deformation speed is 15m / min, and the reduction of each pass is 30-60% (the macro photo of the single pass 40% reduction of the plate is shown in figure 2 As shown in (c), the crack depth on the edge of the plate does not exceed 10mm, and the surface has no cracks, and has good rolling performance). A...

Embodiment 3

[0052] 1) Take pure Mg ingots, pure Zn ingots and Mg-30Ca master alloy as raw materials, and mix according to the weight percentage of Mg-0.73Zn-0.12Ca alloy composition (No. 3 in Table 1);

[0053] 2) Using metal mold gravity casting, Mg-Zn-Ca alloy is cast into an ingot of 150mm×200mm×200mm by conventional magnesium alloy melting; the number of second phases in the as-cast structure of the alloy is very small and the size is not large, such as figure 1 (b) Shown;

[0054] 3) Without homogenization heat treatment, the ingot is directly cut into a 150mm×100mm×20mm billet and milled, and the milled billet is kept at 350°C for rolling; the roll temperature is 250°C; the rolling deformation speed It is 15m / min, the reduction of each pass is 20-60%. After each pass is rolled, it is returned to the furnace for 5-30 minutes to continue rolling until the thickness of the plate is 2mm, the total reduction is 90%, and the edge crack depth of the plate is not Over 10mm, no cracks on the sur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com