Application of polymer particle with chlorine on the surface as thermal reversible reactive filler and composition of polymer particle with chlorine on the surface

A technology of polymer particles and polymer materials, applied in the field of polymer fillers, can solve problems such as environmental pollution and waste of resources, and achieve the effect of excellent reinforcement performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

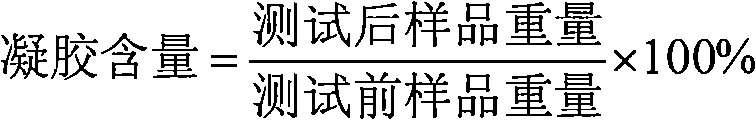

[0023] In the present invention, the emulsion polymerization preparation method of polymer particles containing chlorine on the surface includes the following steps:

[0024] (1) Pre-emulsification: pre-emulsify the vinyl monomer used to form polymer particles under suitable conditions;

[0025] (2) Polymerization of monomers to form particles: Initiator is added to the pre-emulsified material for polymerization reaction, and the temperature is kept for a period of time;

[0026] (3) Particle surface functionalization: In the system obtained in step (2), a chlorine-containing monomer is added dropwise under stirring and nitrogen flow, and the polymerization is continued to obtain polymer particles with chlorine on the surface.

[0027] Wherein, the initiator can use oxidation-reduction initiator systems such as potassium persulfate-sodium bicarbonate, hydrogen peroxide-ferrous sulfate, hydroperoxide-ferrous salt, and water-soluble azo initiators.

[0028] Preferably, in step (1), deioni...

Embodiment 1

[0051] Example 1 Preparation of polymer particle filler containing chlorine on the surface

[0052] Add 65g of styrene monomer into a 1000ml four-necked flask containing 480g of deionized water, bubbling nitrogen to remove oxygen for 10 minutes, set the mechanical stirring speed to 300 rpm, heat to 40°C, and add 1.00g to the system Sodium dodecyl sulfonate, 3.20 g of divinylbenzene and 1.20 g of sodium bicarbonate were stirred and pre-emulsified for 30 minutes. Then the temperature was raised to 89°C, and 2.50g of potassium persulfate initiator dissolved in 40ml of deionized water was added, and the temperature was lowered to 60°C for 6 hours after polymerization. 3.25g of chloromethylated styrene was slowly added dropwise, and the reaction was continued at 60°C. hour. After the completion of the reaction, the obtained particle emulsion is centrifuged and dehydrated, and dried under reduced pressure at 60° C. to obtain a dry powder, which is a reactive polymer particle filler co...

Embodiment 2

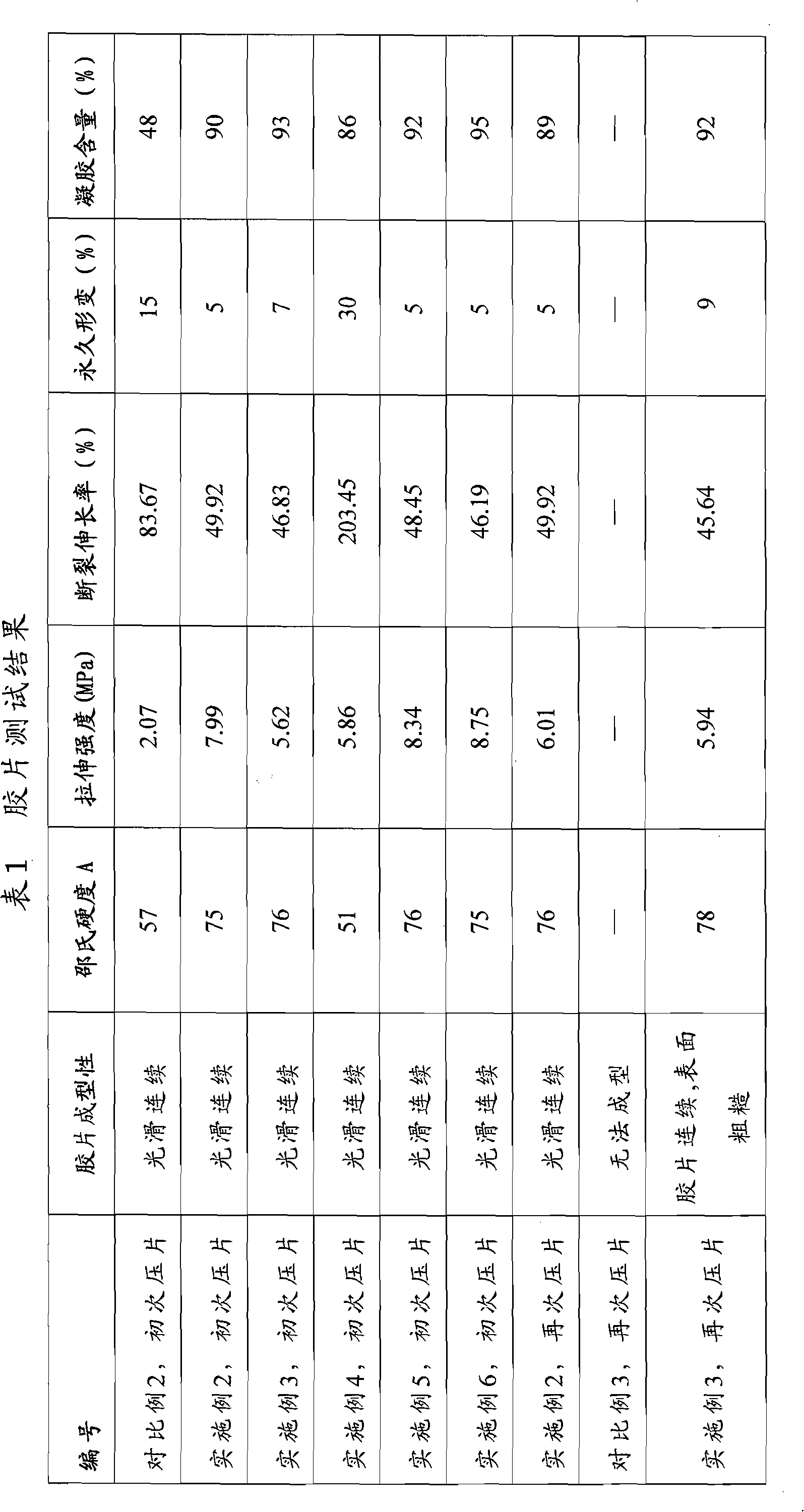

[0055] Example 2 Thermoplastic processable composition using polymerization inhibitor (filling and reinforcement of polymer materials by reactive fillers)

[0056] Add 100g of butadiene pyridine rubber on a two-roll mill, adjust the roll distance to 0.5 mm, mix the rubber sample for 10 minutes, and then add 25g of the polymer reactive filler containing chlorine on the surface of Example 1, 2g of stearic acid, 3g of zinc oxide, 10g of paraffin oil, and 2g of antioxidant 2246 were mixed for 15 minutes. After the mixing, the rubber was stretched on the roller into a thin sheet of uniform thickness. The obtained film was placed in a mold with a length of 135 mm, a width of 115 mm, and a thickness of 2 mm, and was thermoformed at 160° C. for 30 minutes to obtain a filled and crosslinked film.

[0057] Re-thermoplastic processing: Cut the hot-pressed film into small pieces of 65 mm in length and width. After 4 layers are laminated, they are placed in a mold at 180°C and re-heated for 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com