A kind of preparation method and application of biodegradable antioxidant fruit and vegetable fresh-keeping film

A fruit and vegetable preservation and biodegradation technology, which is applied in the field of biodegradable food film processing, can solve the problems of reducing the mechanical properties of the plastic wrap, low elongation at break, and the impact on human health, so as to enhance antibacterial and antioxidative properties and enhance mechanical properties. The effect of high performance and productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

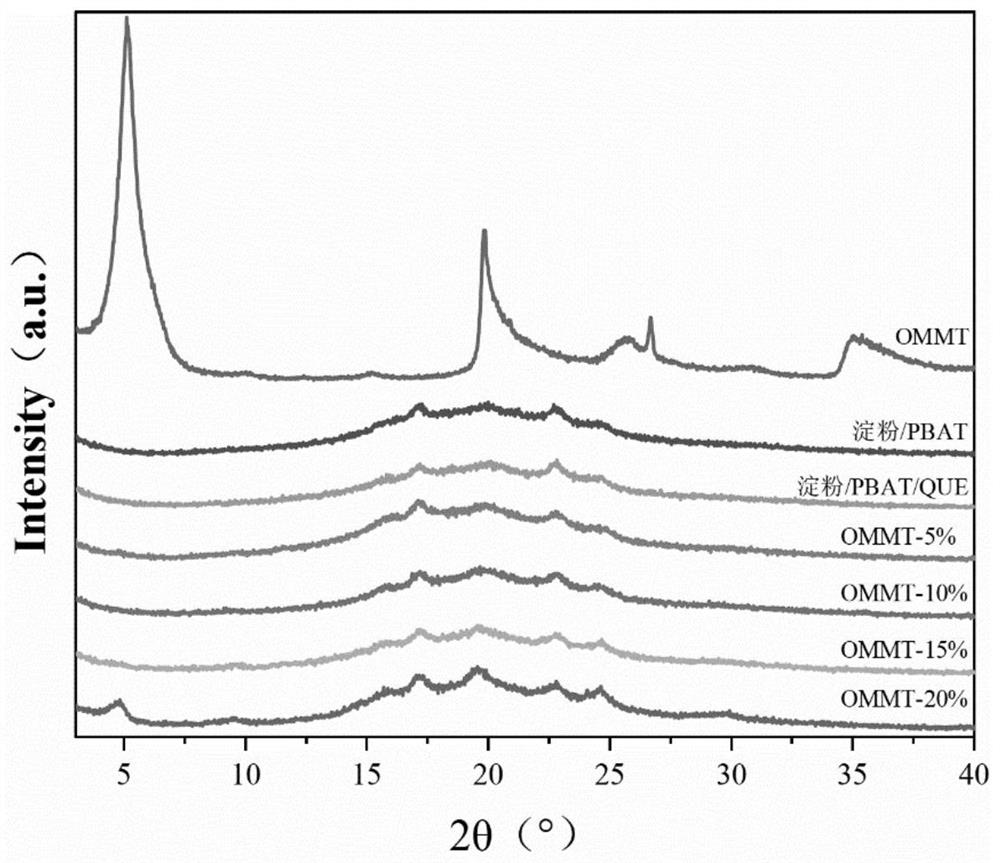

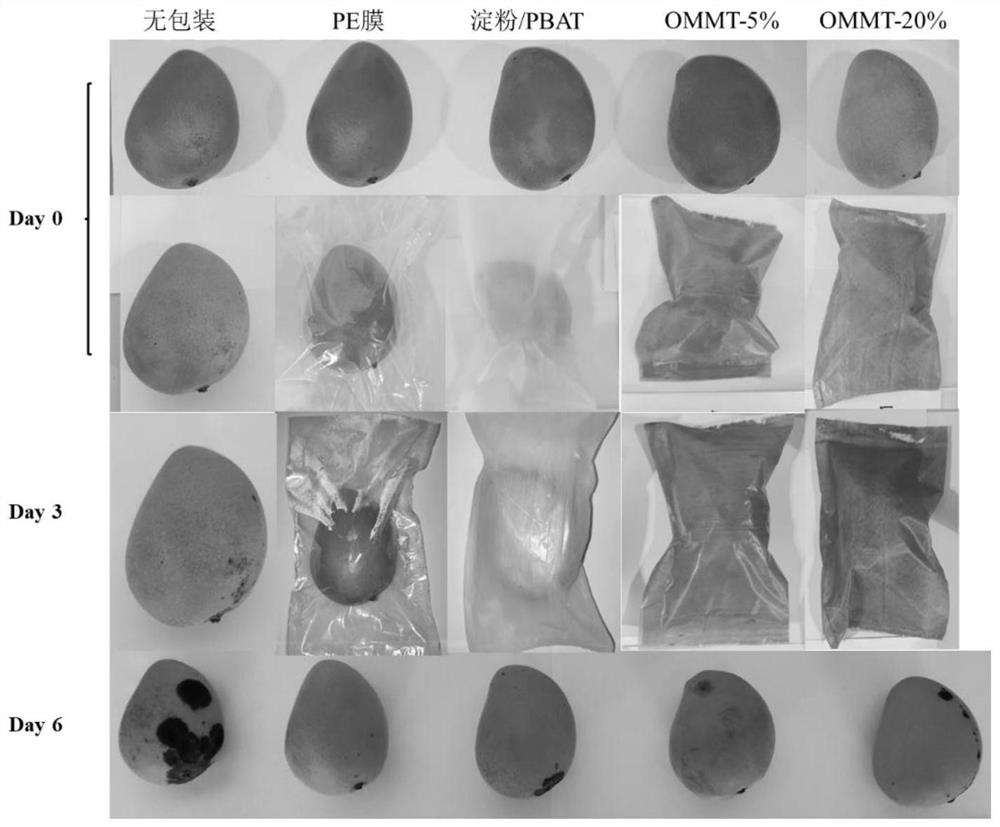

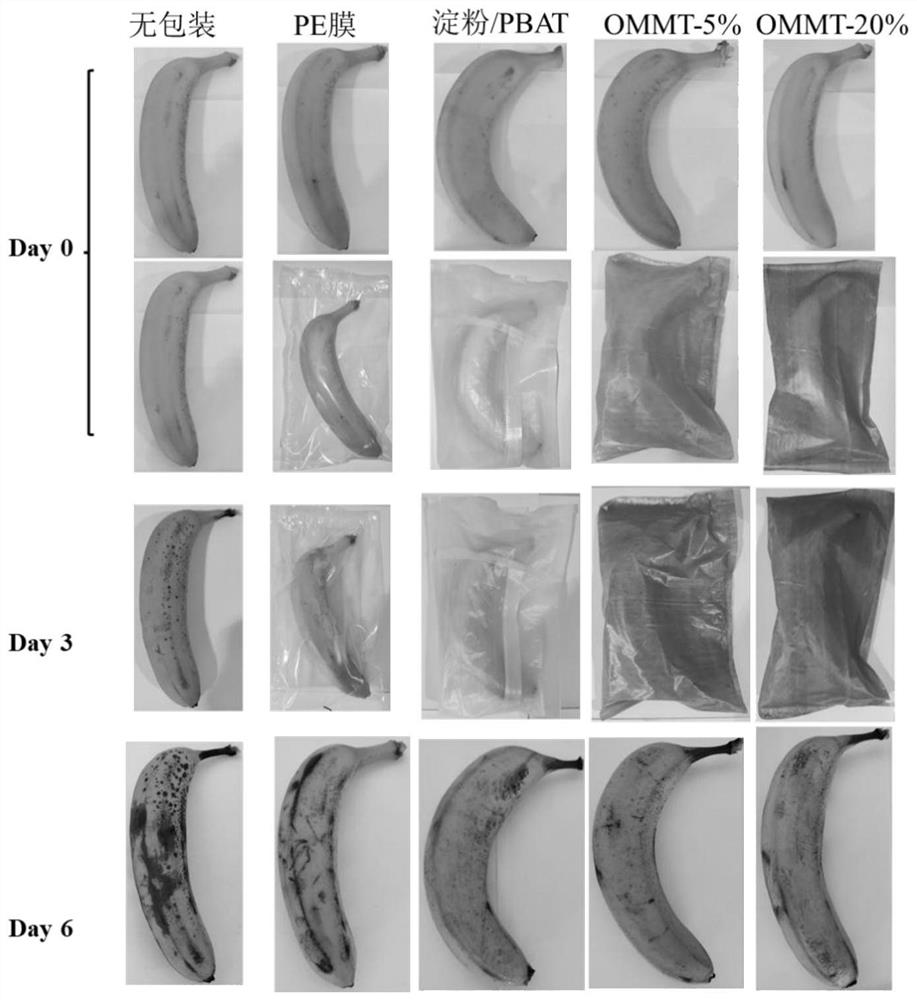

[0032] Weighed in parts by mass, put 100 parts of starch (St), 35 parts of glycerin, 5 parts of organically modified montmorillonite (OMMT) and 1 part of quercetin (QUE) into a high-speed mixer and mix for 5 minutes to obtain modified Powder; the modified powder and PBAT are mixed according to the mass ratio of 4:6, and then twin-screw melt extrusion granulation is carried out. The temperature from the feeding area to the head area of the twin-screw extruder is 110, 120, 130, 140, 120 and 100°C. Then extrude and blow at 140°C with a film blowing machine to obtain a biodegradable anti-oxidation fruit and vegetable fresh-keeping film, which is denoted as OMMT-5%.

Embodiment 2

[0034] Weighed in parts by mass, put 100 parts of starch (St), 35 parts of glycerin, 10 parts of organically modified montmorillonite (OMMT) and 1 part of quercetin (QUE) into a high-speed mixer and mixed for 5 minutes to obtain a modified Powder: The modified powder and PBAT are mixed according to the mass ratio of 4:6, and then twin-screw melt extrusion granulation is carried out. The temperature of each section of the twin-screw extruder is 140°C. Afterwards, a film blowing machine is used to extrude and blow at 110° C. to obtain a biodegradable anti-oxidation fruit and vegetable fresh-keeping film, which is recorded as OMMT-10%.

Embodiment 3

[0036] Weighed in parts by mass, put 100 parts of starch (St), 35 parts of glycerin, 15 parts of organically modified montmorillonite (OMMT) and 1 part of quercetin (QUE) into a high-speed mixer and mix for 5 minutes to obtain a modified Powder: The modified powder and PBAT are mixed according to the mass ratio of 4:6, and then twin-screw melt extrusion granulation is carried out. The temperature of each section of the twin-screw extruder is 120°C. Afterwards, a film blowing machine is used to extrude and blow at 120°C to obtain a biodegradable anti-oxidation fruit and vegetable fresh-keeping film, which is marked as OMMT-15%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com