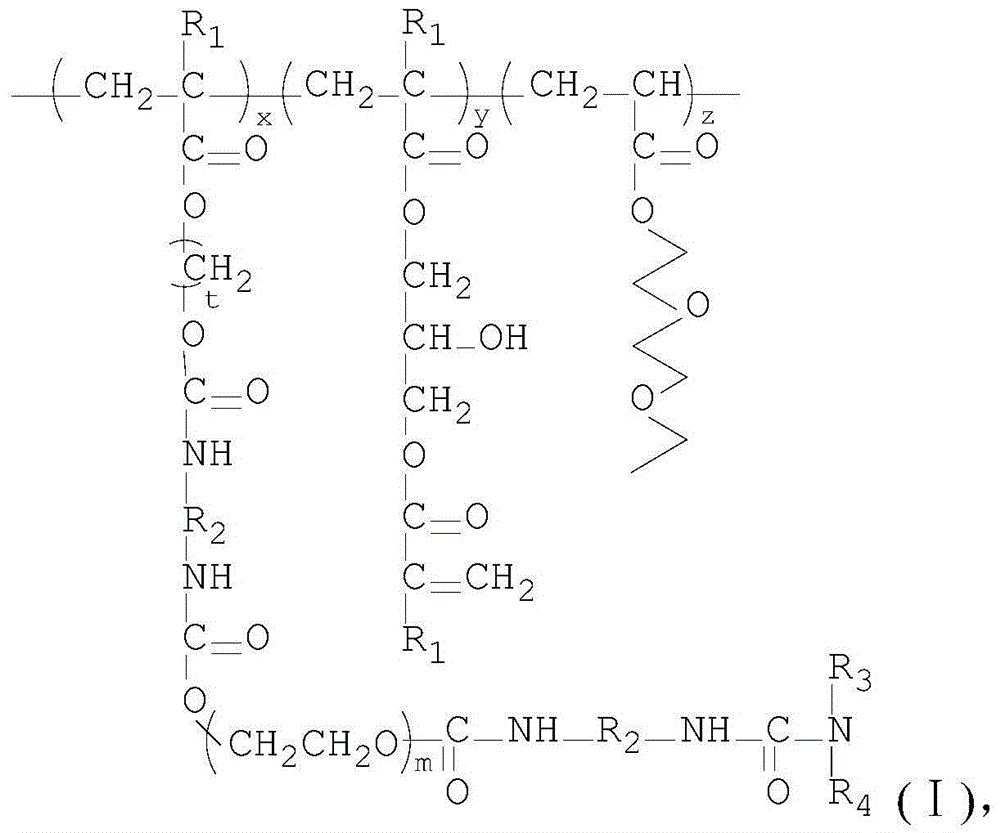

Light-curable polyurethane-poly(methyl) acrylate pressure-sensitive polymer and preparation method thereof

A technology of acrylate and hydroxyacrylate, which is applied in the field of polyurethane polyacrylate pressure-sensitive polymer and its preparation method, can solve problems such as internal stress cannot be released, bonded materials fall off, and affect the use of pressure-sensitive adhesives, etc., to achieve excellent Flexibility and low shrinkage, good elasticity, excellent dilution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of photocurable polyurethane polymethacrylate pressure-sensitive polymer S1

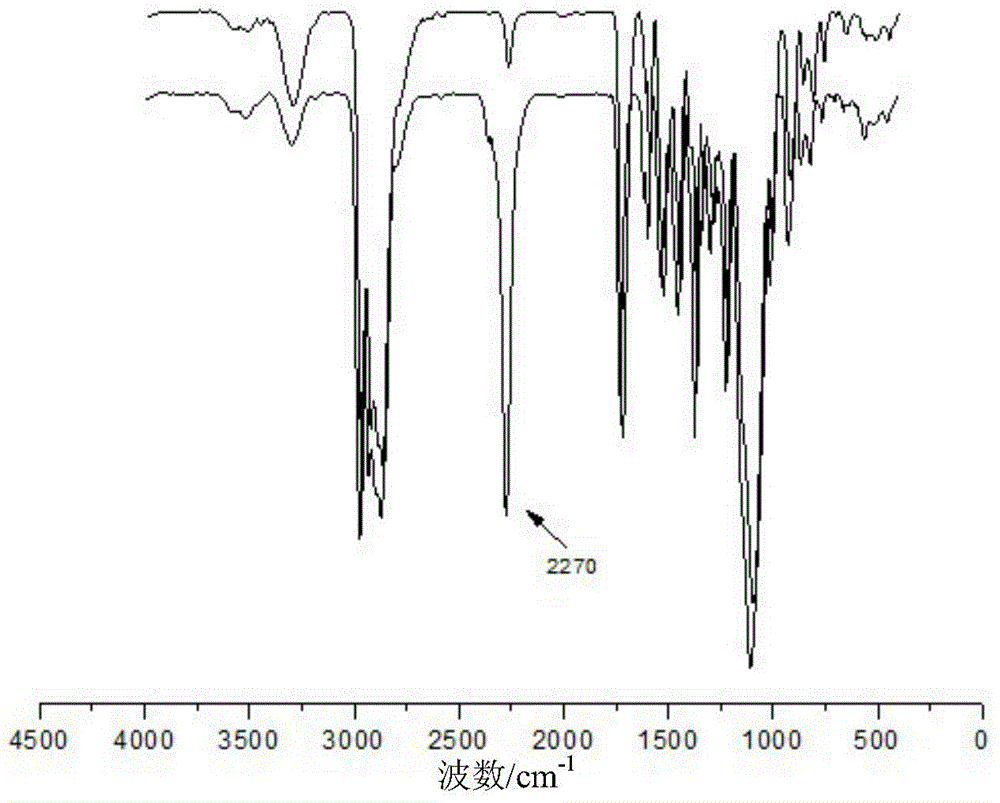

[0037] (1) Add 100 parts by weight of polyether diol that has been dehydrated into a reactor equipped with a stirrer and a thermometer, mechanically stir at a speed of 300r / min and heat to 60°C, then add 14 parts by weight of toluene diisocyanate , mixed evenly under stirring conditions, and reacted for 4 hours to obtain a polyurethane prepolymer with -NCO- at both ends; then added 1.5 parts by weight of diethylamine to single-end -NCO-, continued to react for 4 hours, and then took a sample Test, its infrared spectrogram results show that part of the diethylamine-terminated polyurethane macromonomer has been obtained.

[0038] (2) Add 200 parts by weight of cyclohexanone, 8 parts by weight of hydroxyethyl methacrylate (HEMA), 10 parts by weight of glycidyl methacrylate (GMA), and 82 parts by weight of oxyethoxyethyl acrylate and 1.6 parts by weight of azobisisobutylcya...

Embodiment 2

[0044] Example 2: Preparation of photocurable polyurethane polyacrylate pressure-sensitive polymer S2

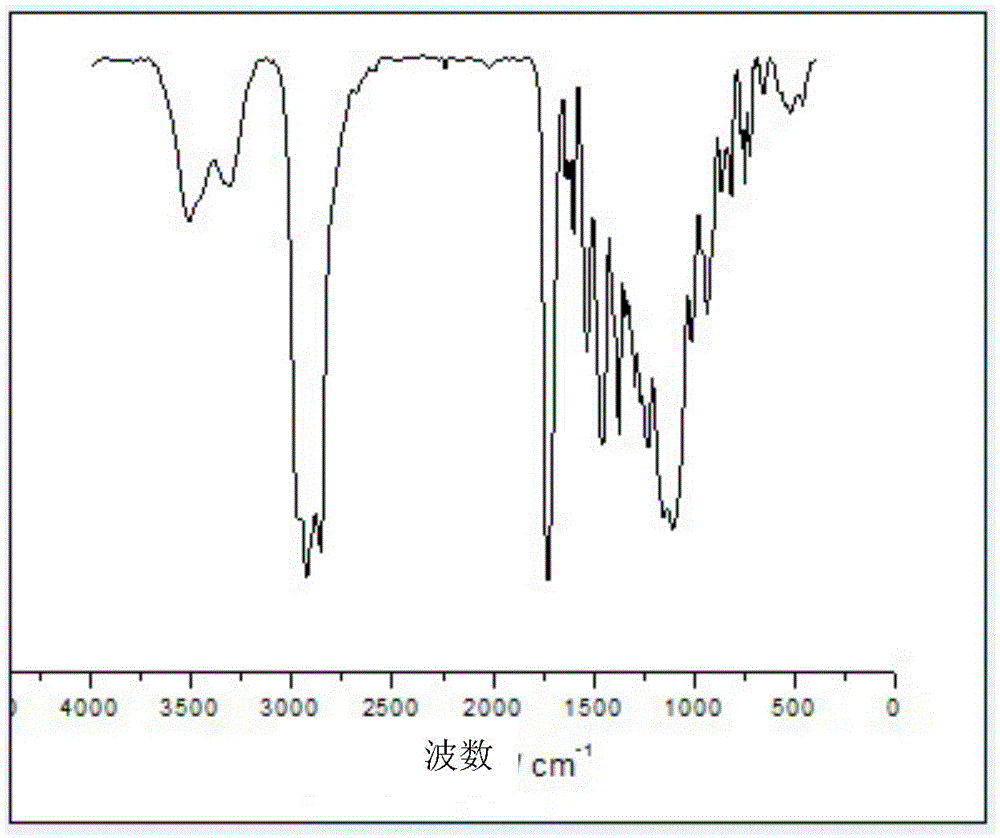

[0045] (1) Add 100 parts by weight of polyether diol that has been dehydrated into a reactor equipped with a stirrer and a thermometer, stir and heat to 80°C, then add 40 parts by weight of diphenylmethane diisocyanate, at 350r / The rotating speed of min is mechanically stirred and mixed evenly. After 5 hours of reaction, a polyurethane prepolymer with -NCO- at both ends is obtained; then 3 parts by weight of dipropylamine is added to single-end the -NCO-, and the reaction is continued for 4 hours. After the sample is tested, Its infrared spectrogram results show that at 3335cm -1 The -NH- stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at , indicating that the isocyanate group of diphenylmethane diisocyanate reacted with the hydroxyl group of polyether diol, 3650cm -1 The O-H stretching vibration peak disappears, indicating ...

Embodiment 3

[0050] Example 3: Preparation of photocurable polyurethane polyacrylate pressure-sensitive polymer S3

[0051] (1) Add 100 parts by weight of polyether diol that has been dehydrated into a reactor equipped with a stirrer and a thermometer, stir and heat to 70°C, then add 10 parts by weight of xylylene diisocyanate, and heat at 300r / min speed mechanically stirred and mixed evenly, after 2 hours of reaction to obtain a polyurethane prepolymer with -NCO- at both ends; then add 1 weight part of dibutylamine to single-end -NCO-, continue to react for 4 hours and then take samples Test, its infrared spectrum results show that at 3335cm -1 The -NH- stretching vibration peak appeared at 1730cm -1 The carbonyl stretching vibration peak appeared at , indicating that the isocyanate group of xylylene diisocyanate reacted with the hydroxyl group of polyether diol, 3650cm -1 The O-H stretching vibration peak disappears, indicating that some dibutylamine-terminated polyurethane macromonom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com