TiSiN-WS2/Zr-WS2 coated cutting tool and preparation process thereof

A zr-ws2, cutting tool technology, applied in the direction of metal material coating process, coating, layered products, etc., can solve the problems of high friction coefficient, low coating hardness, easy to wear and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

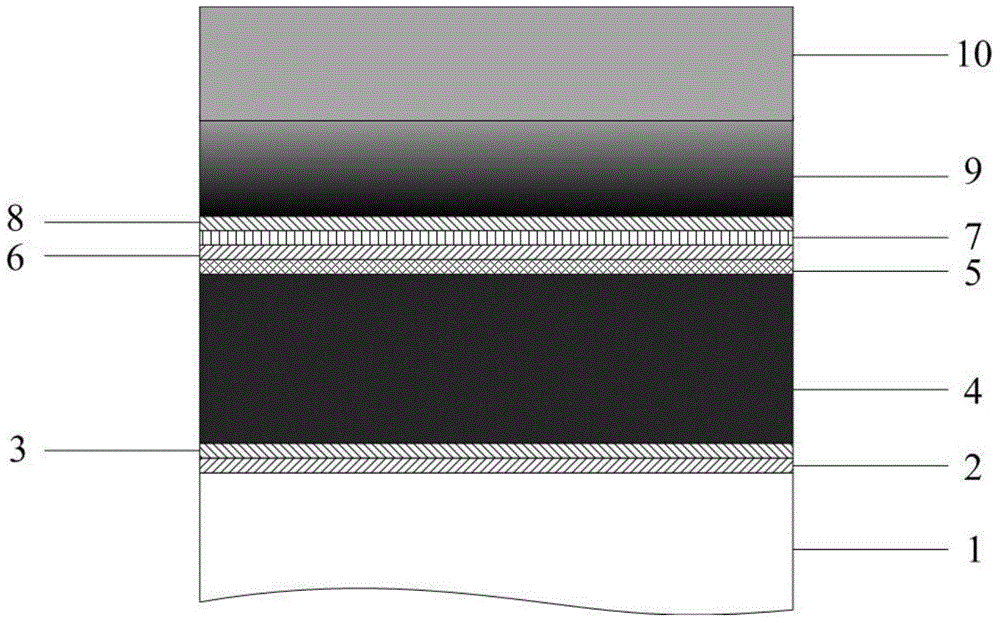

[0020] TiSiN-WS 2 / Zr-WS 2 Coated tool and its preparation process. The base of the tool is YS8 cemented carbide turning tool. From the base to the surface of the tool, the order is: Ti+TiN transition layer, TiSiN layer, TiN+Ti+Ti / Zr+Zr transition layer, WS 2 / Zr layer, WS 2 layer. It is prepared by the method of multi-arc ion plating + intermediate frequency magnetron sputtering, and the specific steps are as follows:

[0021] (1) Pretreatment: Polish the substrate YS8 cemented carbide to the mirror surface, remove the surface contamination layer, and put

[0022] In alcohol and acetone, ultrasonically clean for 15 minutes each time to remove surface oil, and put it into the

[0023] Coating machine vacuum chamber, vacuum chamber background vacuum 7.0×10 -3 Pa, heat to 200°C, keep warm for 30min;

[0024] (2) Ion cleaning: Ar gas is introduced, the air pressure is 1.5Pa, the pulse bias power supply is turned on, the voltage is 800V, the duty cycle is 0.2, the glow clean...

Embodiment 2

[0032] TiSiN-WS 2 / Zr-WS 2Coated tool and its preparation process, the base of the tool is YG6X carbide twist drill, from the base to the surface of the tool are: Ti+TiN transition layer, TiSiN layer, TiN+Ti+Ti / Zr+Zr transition layer, WS 2 / Zr layer, WS 2 layer. It is prepared by the method of multi-arc ion plating + intermediate frequency magnetron sputtering, and the specific steps are as follows:

[0033] (1) Pre-treatment: Polish the substrate YG6X hard alloy, remove the surface contamination layer, put it in alcohol and acetone in turn, ultrasonically clean it for 15 minutes each time, remove the surface oil, and put it into the vacuum chamber of the coating machine after it is fully dried. Bottom vacuum 7.0×10 -3 Pa, heat to 200°C, hold for 50min;

[0034] (2) Ion cleaning: Introduce Ar gas, the air pressure is 1.5Pa, turn on the pulse bias power supply, the voltage is 900V, the duty cycle is 0.2, the glow cleaning is 15min, the bias voltage is reduced to 200V, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com