High-strength aluminum alloy bar and preparing method thereof

An aluminum alloy and aluminum-silicon alloy technology, applied in the field of high-strength aluminum alloy bars and their preparation, can solve the problems of low material plasticity, infrequent application, waste of energy, etc., and achieve fine grains, no energy waste, natural placement obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

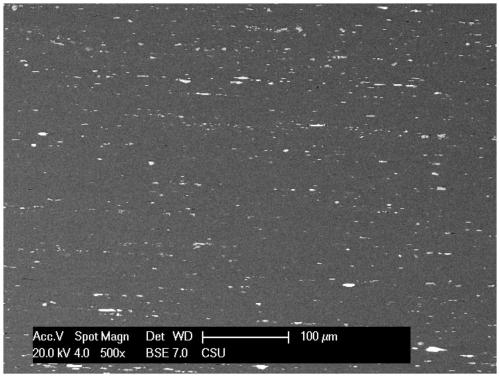

Image

Examples

Embodiment 1

[0029] A high-strength aluminum alloy bar, the aluminum alloy includes the following elements in terms of mass percentage: Mg 0.70-0.90%, Si 0.55-0.65%, Mn 0.70-0.80%, Cu 3.7-4.3%, Fe≤0.50%, Cr ≤0.10%, Zn≤0.10%, Zr0.02~0.06%, Ti 0.02~0.06%, the balance is Al and unavoidable impurity elements, the single content of impurity elements is ≤0.05%, and the total amount of impurity elements is ≤0.15%.

[0030] The solid solubility of Mg in aluminum alloy extruded rods is relatively high, which can improve the strength of aluminum alloy extruded rods through solid solution strengthening. Mg and Si also form Mg 2 The Si strengthening phase enhances the strength of aluminum alloy extruded rods. The higher the Mg content, the higher the strength of the aluminum alloy extruded rod. Combined with the Si element content, the Mg content is 0.7-0.9%.

[0031] In addition to forming Mg with Mg, Si 2 In addition to the Si strengthening phase enhancing the strength of aluminum alloy extruded...

Embodiment 2

[0051] On the basis of Example 1, this Example 2 provides a high-strength aluminum alloy rod and its preparation method. The aluminum alloy includes the following elements by mass percentage: Mg 0.75%, Si 0.60%, Mn 0.77%, Cu 4.0%, Fe0.17%, Ti 0.04%, Zr 0.04%, the balance is Al and unavoidable impurity elements, the individual content of impurity elements is ≤0.05%, and the total amount of impurity elements is ≤0.15%.

[0052] In the steps of the preparation method of the aluminum alloy extruded rod:

[0053] The first step: prepare materials according to the requirements of chemical composition standards, and prepare raw materials such as aluminum ingots, magnesium ingots, aluminum-silicon alloys, aluminum-manganese alloys, aluminum-copper alloys, aluminum-zirconium alloys and aluminum-titanium-boron alloy rods;

[0054] Step 2: Add aluminum ingots to the melting furnace to heat up and melt, measure the temperature at 735°C, then add magnesium ingots, aluminum-silicon alloys, ...

Embodiment 3

[0062] On the basis of Example 1, a high-strength aluminum alloy rod that can be obtained through natural aging and its preparation method, the aluminum alloy includes the following elements in terms of mass percentage: Mg 0.75%, Si 0.56%, Mn 0.79% , Cu4.1%, Fe 0.20%, Ti 0.04%, Zr 0.04%, the balance is Al and unavoidable impurity elements, the individual content of impurity elements is ≤0.05%, and the total amount of impurity elements is ≤0.15%.

[0063] In the steps of the preparation method of the aluminum alloy extruded rod:

[0064] The first step: prepare materials according to the requirements of chemical composition standards, and prepare raw materials such as aluminum ingots, magnesium ingots, aluminum-silicon alloys, aluminum-manganese alloys, aluminum-copper alloys, aluminum-zirconium alloys and aluminum-titanium-boron alloy rods;

[0065] Step 2: Add aluminum ingots to the melting furnace to heat up and melt, measure the temperature at 750°C, then add magnesium ingo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

| Room temperature tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com