Aluminum alloy containing scandium, titanium and zirconium elements for 3D printing

A 3D printing, aluminum alloy technology, applied in the direction of additive processing, etc., can solve the problem of few aluminum alloy grades, achieve good plasticity and process feasibility, improve process feasibility, and enrich the effect of available material library

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

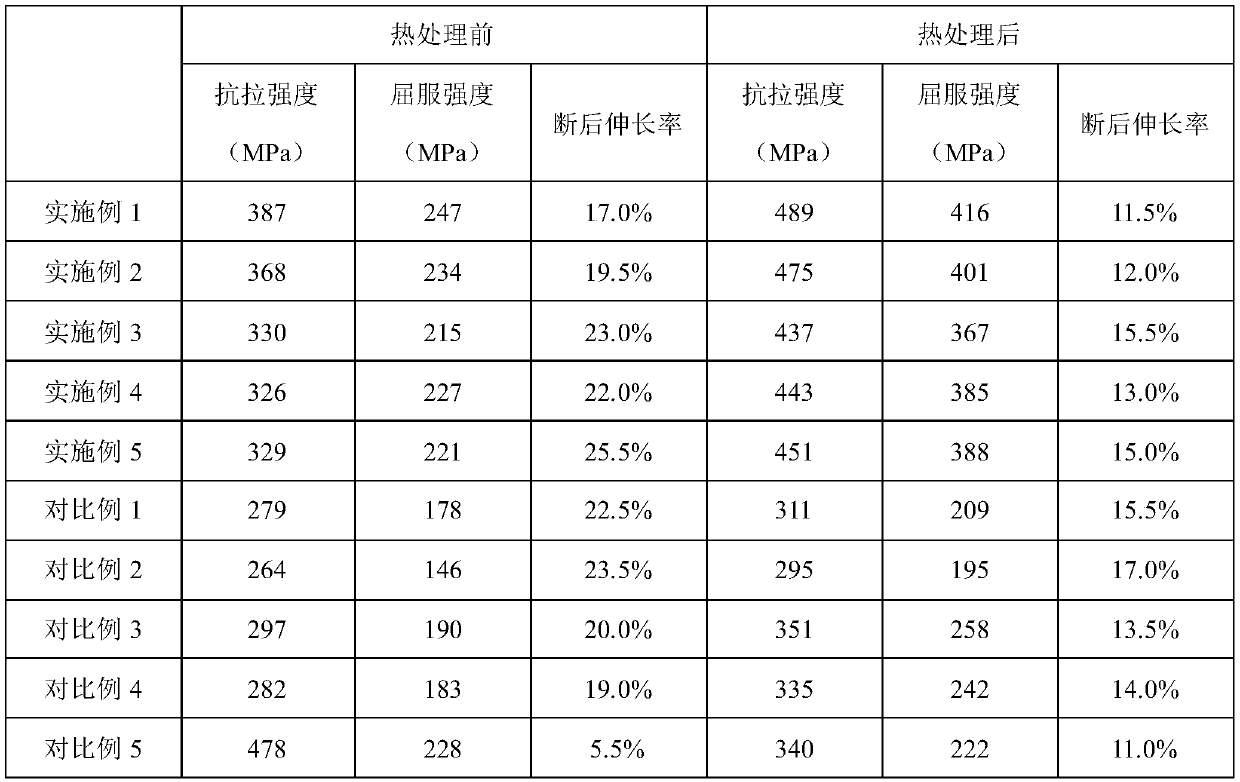

Embodiment 1

[0031] This example provides a special aluminum alloy for 3D printing containing scandium, titanium and zirconium elements. The composition of the raw materials is calculated according to the following weight percentages: Mg: 1.9%, Mn: 3.1%, Sc: 0.3%, Ti: 0.35%, Zr: 0.35%, O: 0.035%, the total weight percentage of impurity elements Fe, Si, Cu, Zn, Cr, Ni, Pb, Sn is 0.2%, the total weight percentage of other non-removable impurities is 0.1%, and the balance is Al .

Embodiment 2

[0033] This embodiment provides a special aluminum alloy for 3D printing containing scandium, titanium and zirconium elements, and the composition of the raw materials is calculated according to the following weight percentages:

[0034] Mg: 2.4%, Mn: 2.7%, Sc: 0.8%, Ti: 0.18%, Zr: 0.12%, O: 0.051%, the weight percentage of impurity elements Fe, Si, Cu, Zn, Cr, Ni, Pb, Sn The total amount is 0.4%, the total weight percentage of other non-removable impurities is 0.15%, and the balance is Al.

Embodiment 3

[0036] This example provides a special aluminum alloy for 3D printing containing scandium, titanium and zirconium elements. The raw material composition is calculated according to the following weight percentages: Mg: 4.1%, Mn: 1.1%, Sc: 0.25%, Ti: 0.45%, Zr: 0.35%, O: 0.039%, the total weight percentage of impurity elements Fe, Si, Cu, Zn, Cr, Ni, Pb, Sn is 0.15%, the total weight percentage of other non-removable impurities is 0.08%, and the balance is Al .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com