Patents

Literature

33results about How to "Reduce surface residual alkali content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

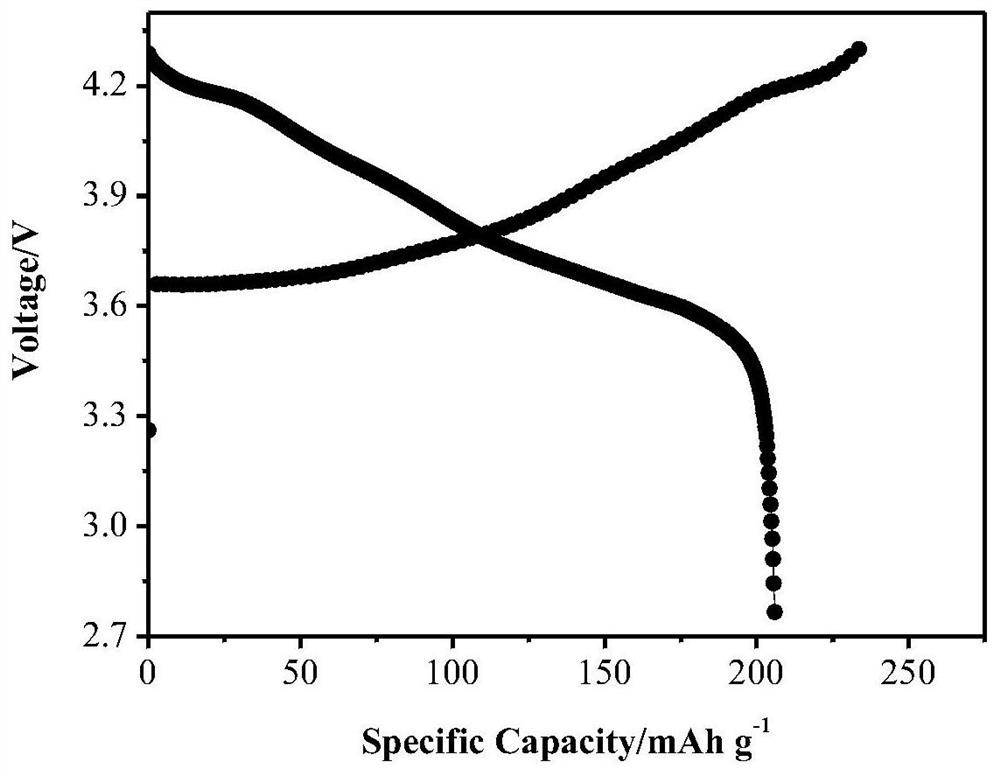

Preparation method of cobaltous oxide coated ternary anode material

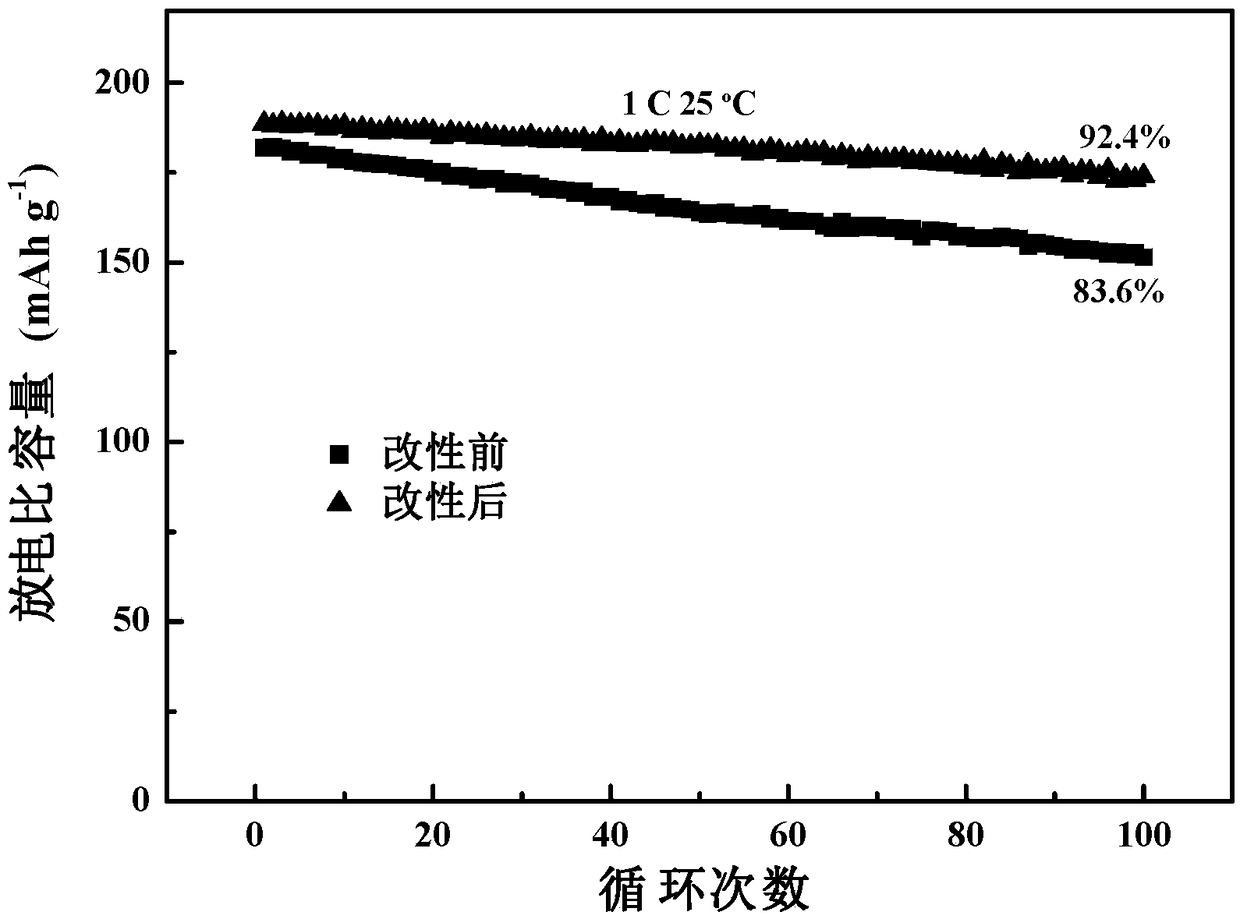

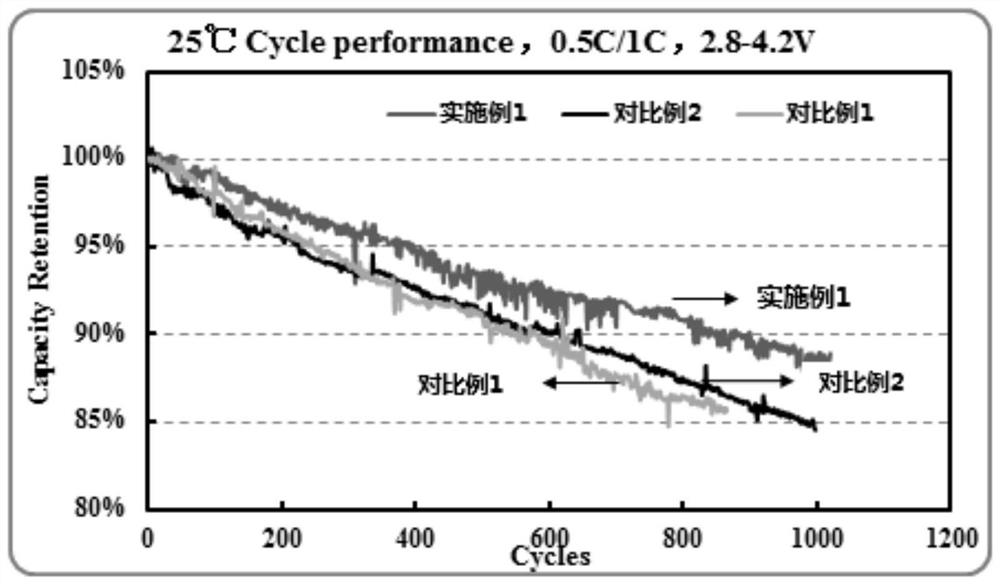

InactiveCN106532006AReduce surface residual alkali contentImprove cycle performanceCell electrodesSecondary cellsCoprecipitationLithium-ion battery

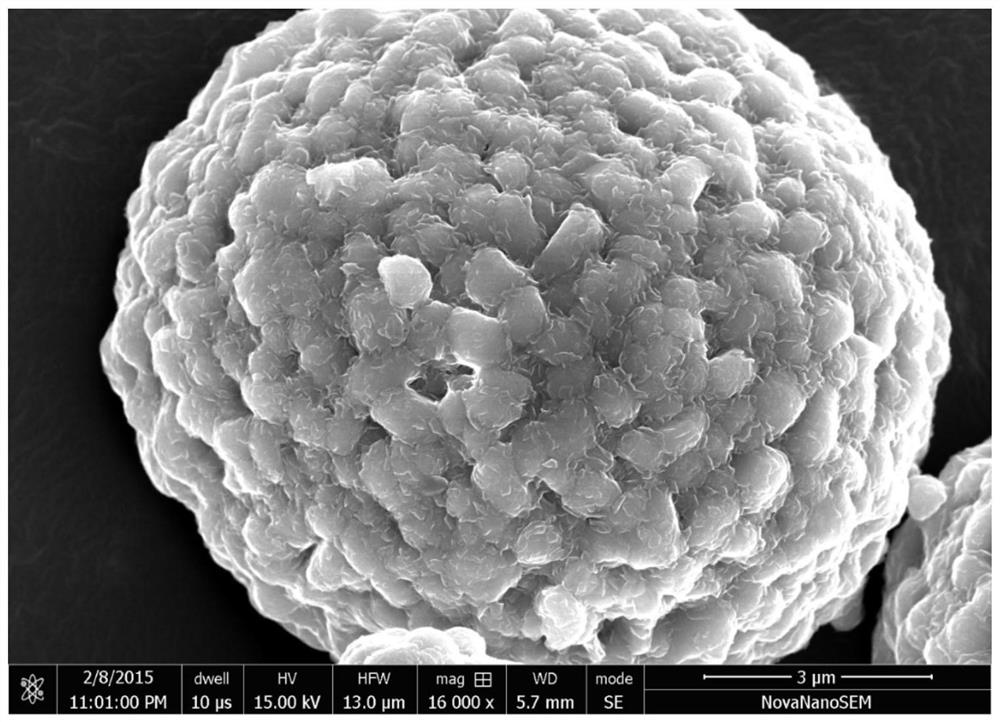

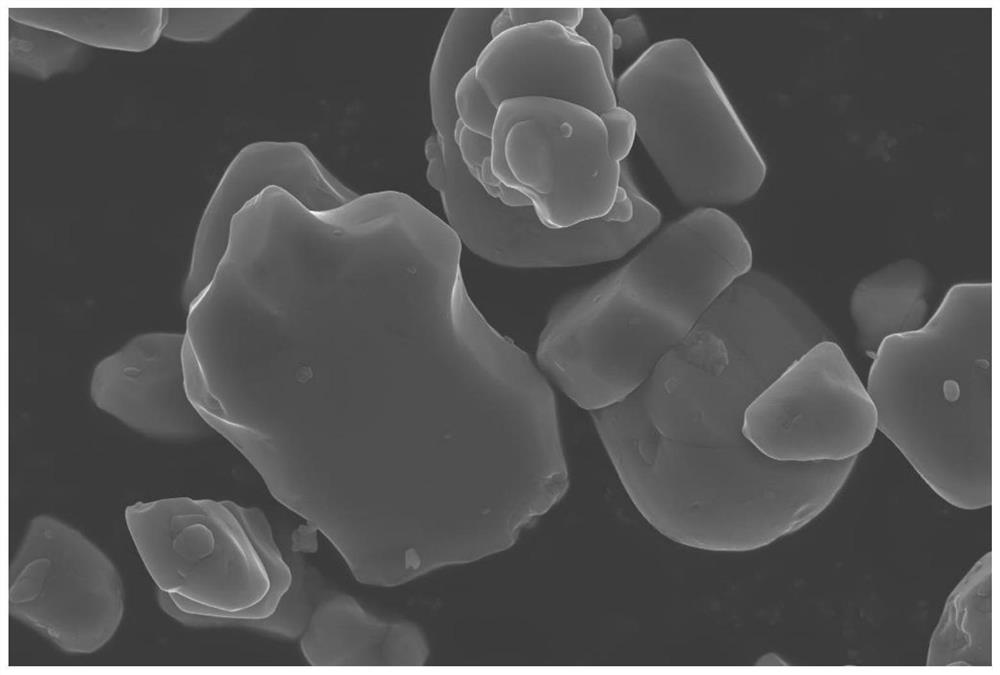

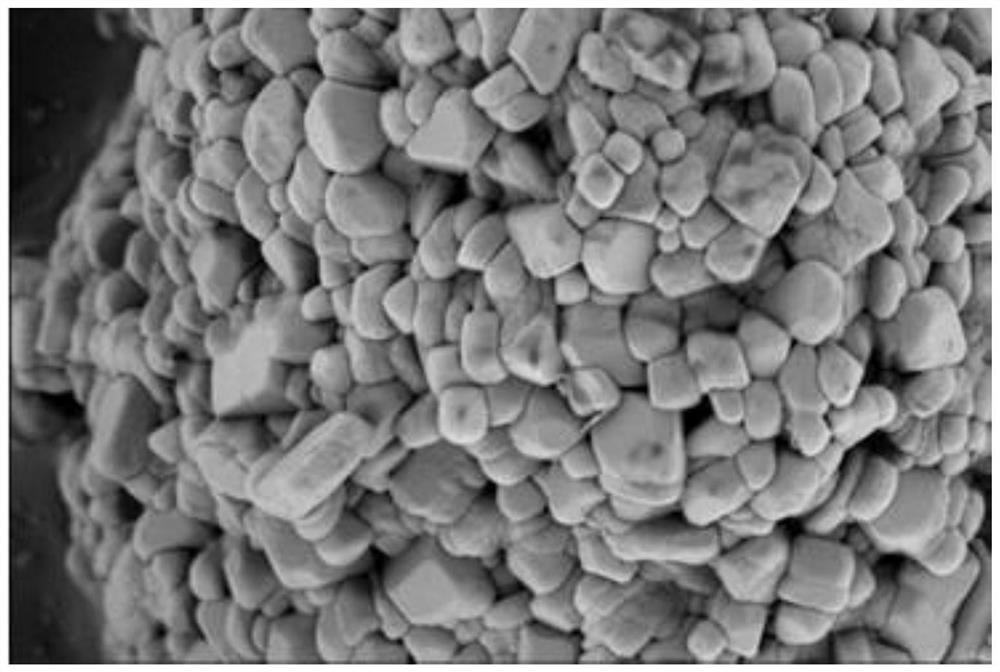

The invention belongs to the field of lithium ion batteries, and particularly relates to a preparation method of a cobaltous oxide coated ternary anode material. The cobaltous oxide coated ternary anode material is prepared through the steps of coprecipitation synthesis of a ternary anode material precursor, high-temperature sintering preparation of the ternary anode material, nanometer cobaltous oxide solid-phase coating and the like, so that the content of residual alkali on the surface of the anode material is reduced, the cycle performance and high-temperature safety performance are improved, and the preparation method is simple and practical and is high in practicability and universality.

Owner:WUXI JEWEL POWER & MATERIALS

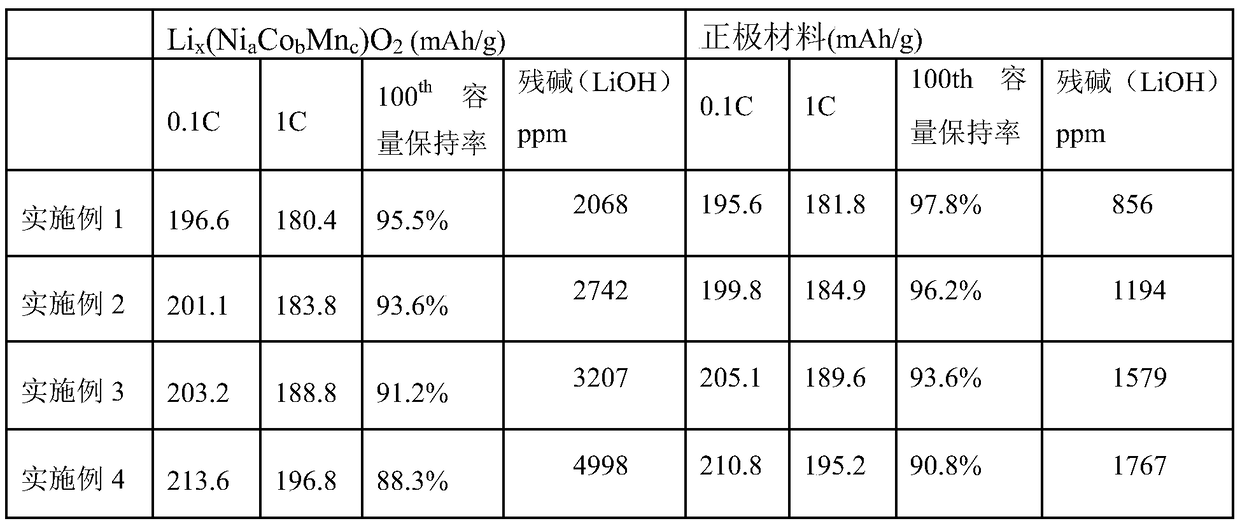

Lithium ion battery cathode material and preparation method thereof

ActiveCN107394160AImprove surface structureReduce surface residual alkali contentMaterial nanotechnologyCell electrodesTwo stepLithium-ion battery

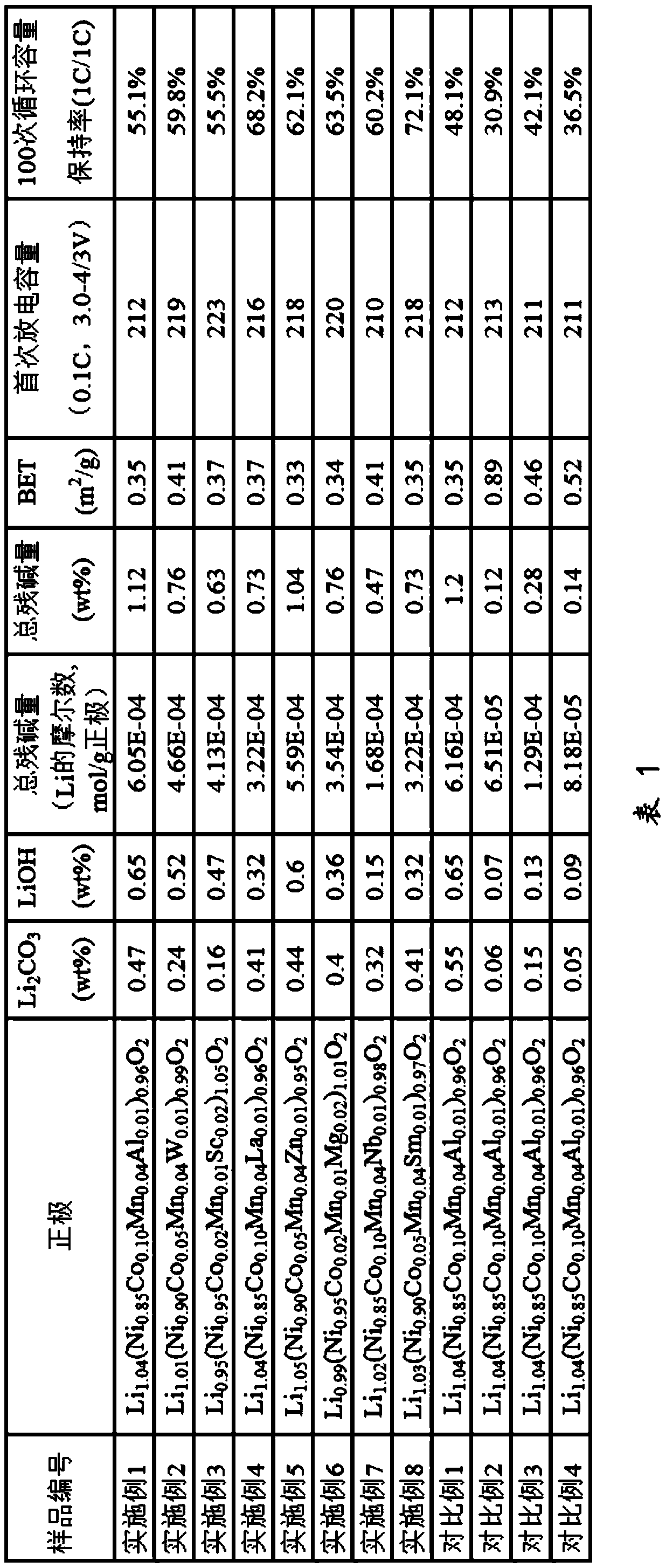

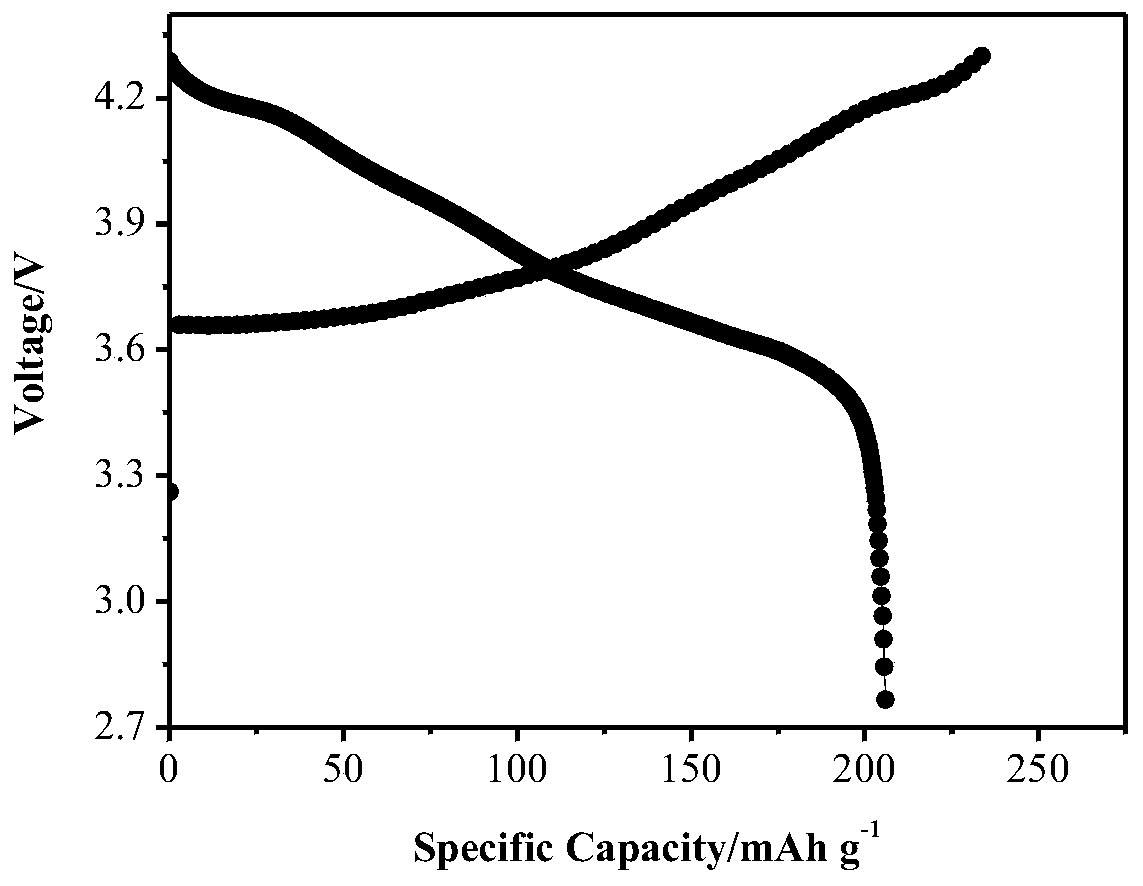

Belonging to the technical field of lithium ion batteries, the invention discloses a lithium ion battery cathode material and a preparation method thereof. The chemical molecular formula of the cathode material is Lix(NiaCobMnc)1-yMyO2, wherein x is greater than or equal to 0.96 and smaller than or equal to 1.04, y is greater than or equal to 0.01 and smaller than or equal to 0.06, a is greater than or equal to 0.8 and smaller than or equal to 0.9, and a+b+c=1, M has a general formula of BzM'1-z, M' is composed of one or several of the following elements: Al, Mg, Ti and Zr, and z is greater than or equal to 0.1 and smaller than or equal to 0.5. The cathode material is coated by a layer of compound containing L, B, Ni, Co and Mn, the content of B in the outermost surface of the coating layer is at least two times that of the B in the innermost layer of the coating layer. According to the invention, the high capacity cathode material is acquired from a high nickel content ternary system, additionally multielement doping is employed to stabilize the crystal structure of the material, and then by means of washing, boron element surface modification and two-step sintering process, the material surface structure can be improved, and the surface residual alkali content can be reduced to improve the interface stability. The whole technological process of the invention is simple, and is easy for large scale production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

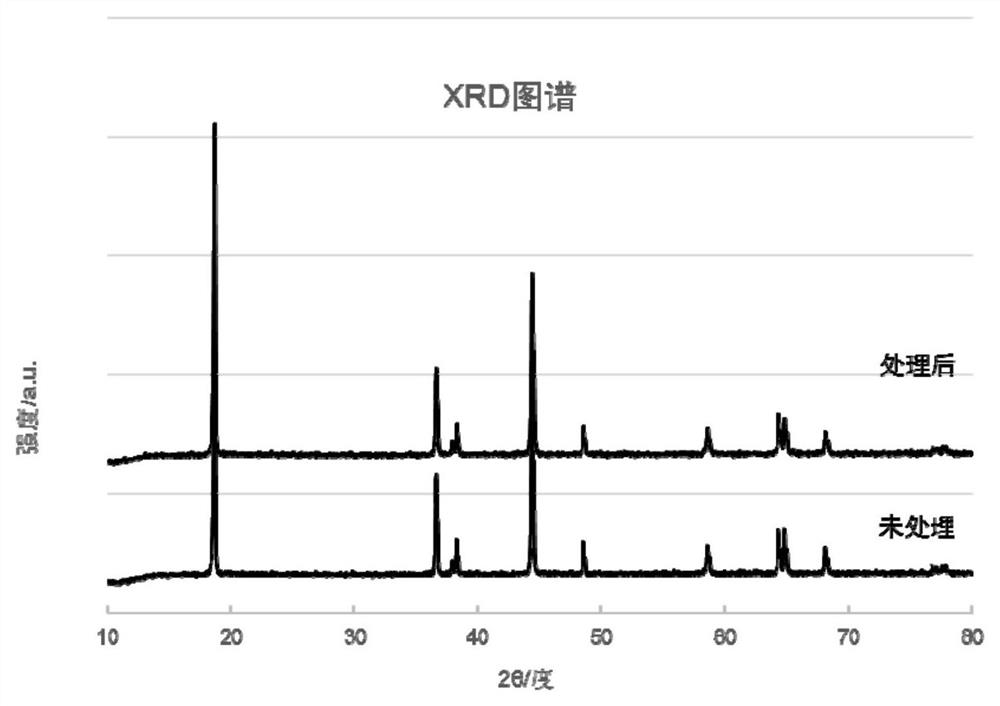

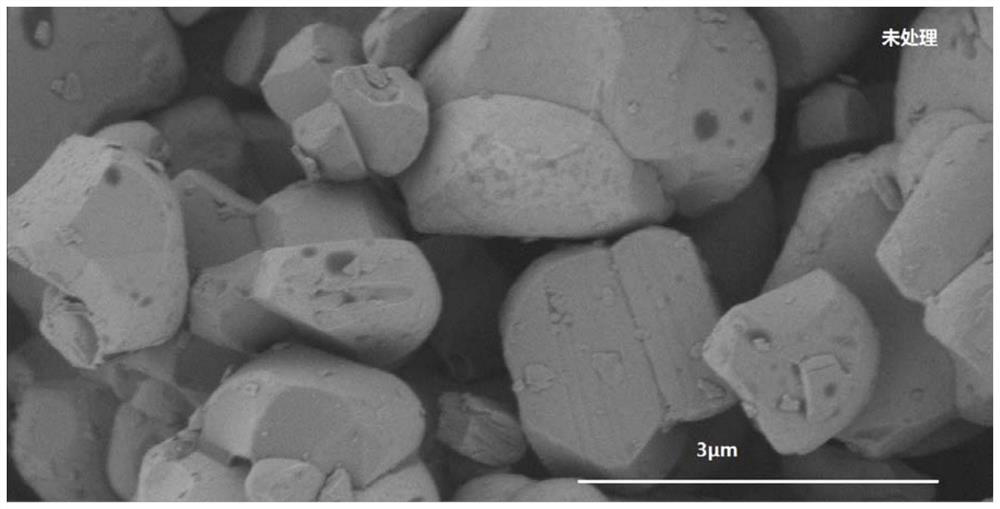

Method for improving residual alkalinity on surface of ternary positive electrode material of lithium ion battery

InactiveCN108878863AReduce surface residual alkali contentImprove interface performanceCell electrodesSecondary cellsAluminium-ion batteryEvaporation

The main idea for solving the problem of excessively high residual alkalinity on a surface of a ternary material is in a way that the residual alkalinity on the surface of the material can be reducedby washing. Although the residual alkalinity on the surface of the high-nickel ternary material can be reduced after washing, and the lithium content after washing is reduced to cause that the specific capacity also can be reduced and the battery performance is affected. The invention discloses a method for improving residual alkalinity on a surface of a ternary positive electrode material of a lithium ion battery. The method comprises the following steps of mixing powdered Ni-Co-Mn layered positive electrode material with molecular formula being LiNi<x>Co<y>Mn<z>O<2> and water, and performingcentrifugal separation to obtain a washed powder material; adding a lithium source to absolute ethyl alcohol for uniformly mixing, adding the washed powder material for uniformly mixing, and performing complete evaporation, drying and sintering to obtain the ternary positive electrode material of the lithium ion battery. After washing, lithium supplement and secondary sintering are performed on the ternary material by an ethyl alcohol system, the lithium which is lost during washing is supplemented, and the performance of the material is improved; and moreover, the process flow is simple, andindustrial production is convenient to implement.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for reducing content of residual alkali on surface of high-nickel cathode material of lithium-ion battery

PendingCN111370684ALess side effectsImprove processing performance and cycle lifeCell electrodesSecondary cellsElectrical batteryOrganosolv

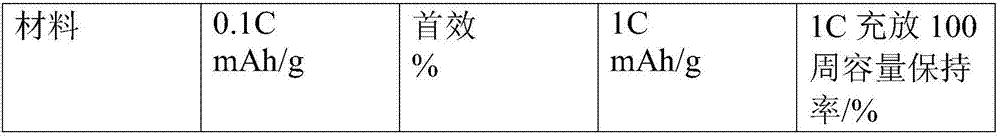

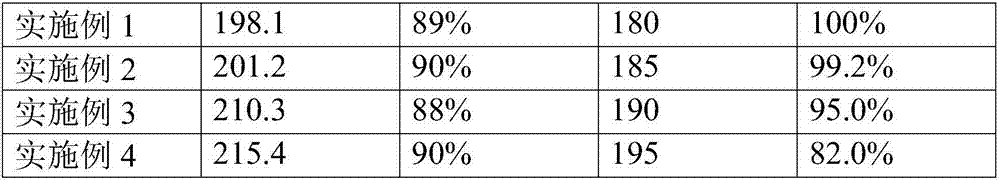

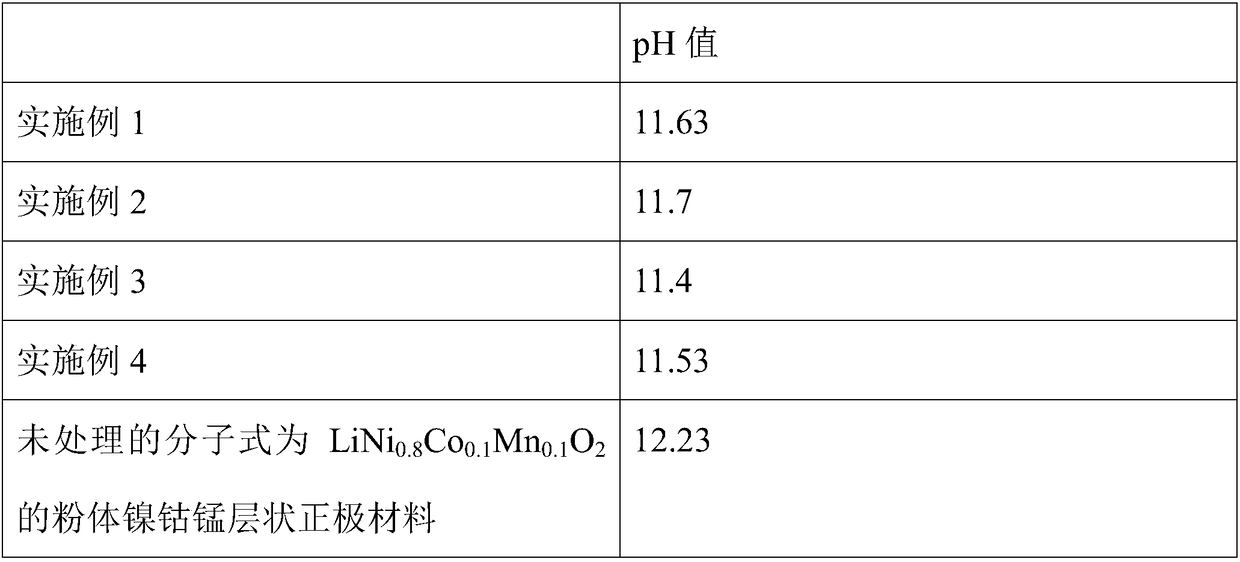

The embodiment of the invention relates to a method for reducing the content of residual alkali on the surface of a high-nickel positive electrode material of a lithium ion battery. The method comprises the following steps: adding a certain amount of acid or a derivative of the acid into a certain amount of non-aqueous inactive hydrogen organic solvent at a stirring speed of 1m / s to 10m / s at normal temperature, and stirring until the acid or the derivative of the acid is completely dissolved, so as to obtain a washing solution for reducing residual alkali on the surface of the high-nickel positive electrode material of the lithium ion battery; wherein the mass ratio of the to-be-treated high-nickel positive electrode material to the non-aqueous non-active hydrogen organic solvent is 1:0.5-1:4; wherein the molar concentration of the acid or the derivative of the acid in the washing liquid is 0.5-1.5 times of the molar weight of the residual alkali on the surface of the to-be-treated high-nickel positive electrode material; adding a to-be-treated high-nickel positive electrode material into the washing liquid while stirring at a linear speed of 1m / s to 10m / s, and stirring for 1 to 120 minutes; and centrifuging to remove the solvent, vacuumizing, heating and drying at 20-80 DEG C to obtain the treated high-nickel positive electrode material.

Owner:TIANMU LAKE INST OF ADVANCED ENERGY STORAGE TECH CO LTD

Method for preparing high-rate nickel cobalt lithium aluminate anode material

ActiveCN107093741AImprove performanceImprove cycle performanceCell electrodesSecondary cellsCyclic processHigh rate

The invention discloses a method for preparing a high-rate nickel cobalt lithium aluminate anode material. The method comprises the following steps: (1) preparing a nickel cobalt lithium aluminate precursor; (2) performing lithium-site doping and modifying on potassium ions; and (3) constructing a cladding layer of a lithium-containing compound. According to the method, the dispersing speed of lithium ions is effectively increased by lithium-site replacement of potassium ions, and the rate capability of a material can be improved; the lithium-containing compound layer constructed on the material surface can be used for reducing the content of alkali remained on the material surface and reduce later cell bubbling; side reaction can be effectively inhibited, and the material structure stability in the cycling process can be promoted; and the lithium-containing compound layer has high conducting performance for lithium ions, embedding and separating of lithium ions can be accelerated, the problem of poor lithium ion conductivity when conventional metal oxide is used as the cladding layer can be solved, and the cycling performance and rate performance of the material can be improved.

Owner:郑州中科新兴产业技术研究院

High-nickel ternary positive electrode material washing method

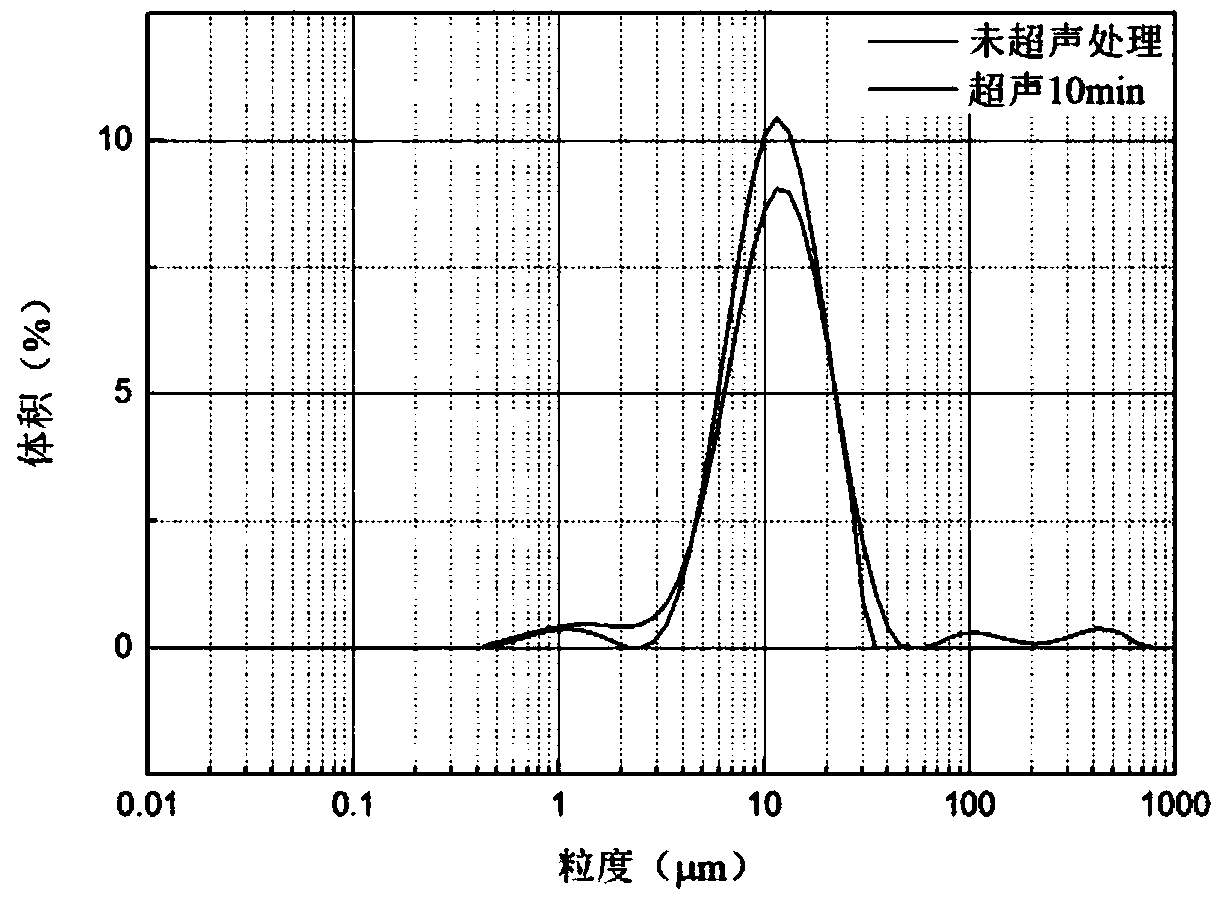

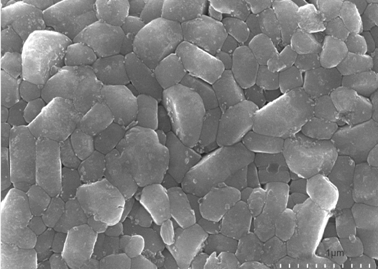

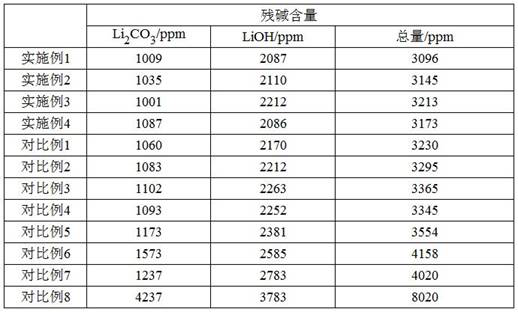

InactiveCN109546088AReduce surface residual alkali contentReduce alkalinityCell electrodesLithium carbonateLithium hydroxide

The invention provides a high-nickel ternary positive electrode material washing method. The method comprises the steps: weighing a certain amount of a lithium battery positive electrode material (NCM622), adding deionized water at a certain solid-liquid ratio, performing stirring for a time period, then performing the ultrasound treatment for a period of time, and then filtering the obtained solution to perform anti-burning for 5h in an oxygen environment under the temperature of 700 DEG C; adding 100g of deionized water to 5g of the powder obtained after drying, performing filtering after stirring, and finally testing the content of lithium carbonate and lithium hydroxide in the filtrate through a potentiometric titration method. The invention provides the water washing method for treating a high nickel ternary positive electrode material by using ultrasonic waves to reduce the residual alkali content on the surface of the material. The method has the advantages of simple process, convenient operation and high product safety.

Owner:CHANGZHOU UNIV

Lithium ion battery positive electrode material with low surface lithium ion content and preparation method thereof

InactiveCN108878819AEvenly dispersedGood coating effectMaterial nanotechnologyCell electrodesIon contentElectrical battery

The invention discloses a lithium ion battery positive electrode material with low surface lithium ion content. The lithium ion battery positive electrode material is characterized by being prepared from nano oxide and Lix (NiaCobMnc)O2 powder at the mass ratio of 2-12:1000 through mixing and sintering; and the content of free lithium on the surface of the positive electrode material is 1,800ppm or below. According to the method, the surface residual alkali content is reduced by water washing and oxide surface coating modification, the content of free lithium on the surface of the material iscontrolled, meanwhile, the crystal structure of the material can be stabilized, and the cycling stability and the safety performance of the material are improved. According to the method disclosed bythe invention, the whole process flow is simple, and a liquid phase coating method is synchronously carried out in the process of water washing and residual alkali reducing, so that the process flow is simplified; and meanwhile, the liquid-phase coating uniformity is higher, so that the large-scale production can be executed easily.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

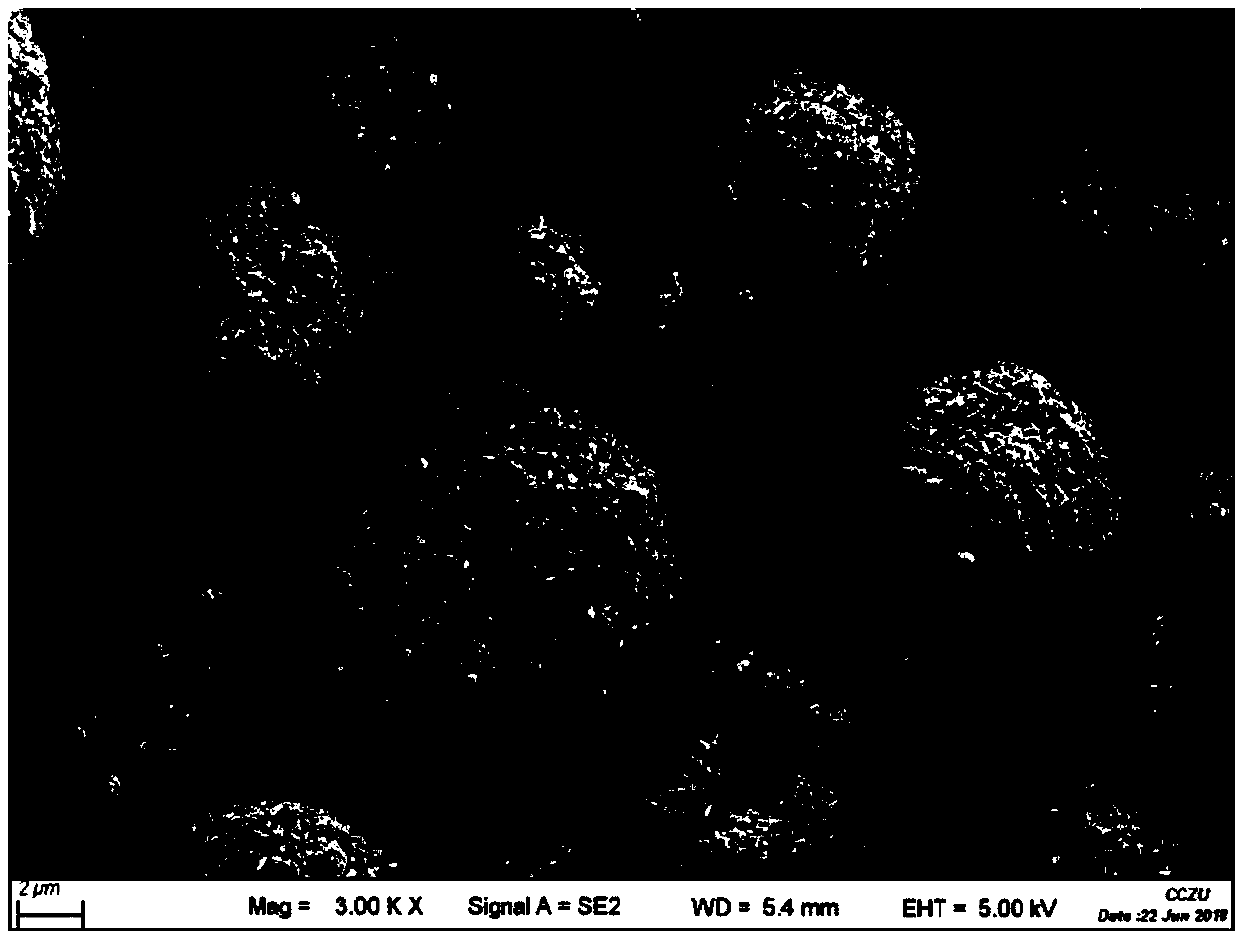

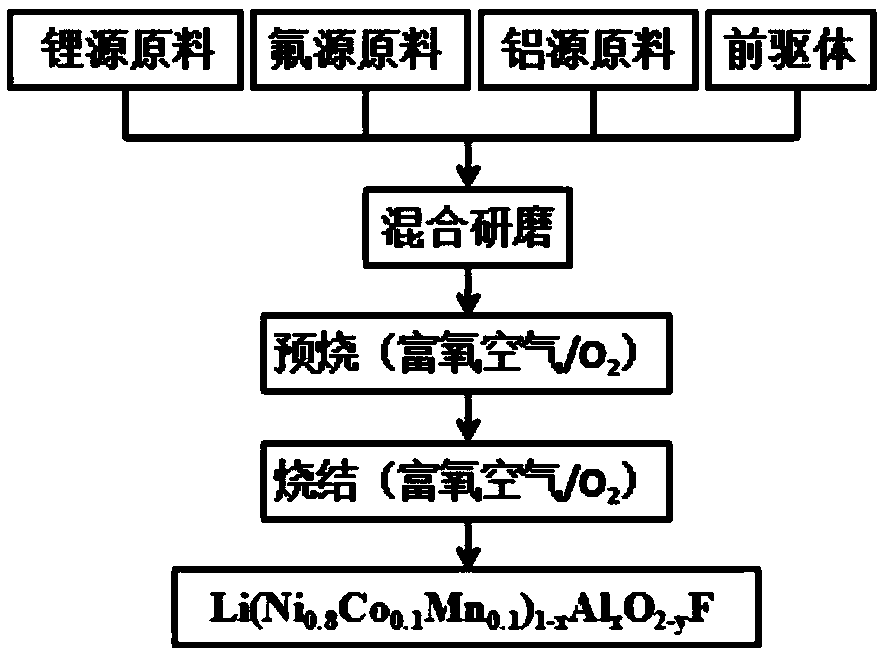

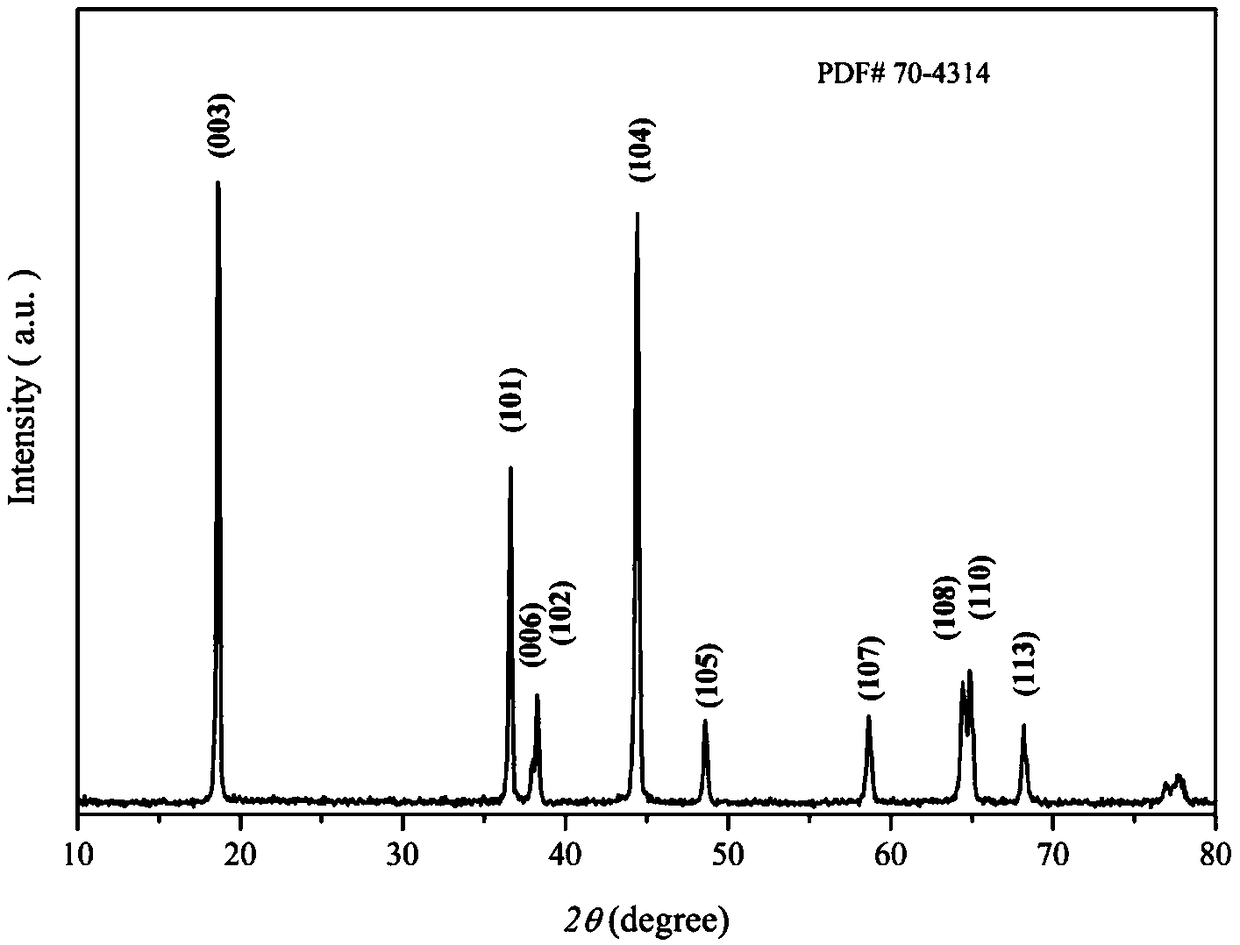

Aluminum and fluorine dual-modified lithium ion battery cathode material and preparation method thereof

InactiveCN108807887AEasy transferStable internal structureCell electrodesSecondary cellsLithium aluminateSide reaction

The invention belongs to the field of lithium ion batteries, and provides a lithium ion battery cathode material Li(Ni0.8Co0.1Mn0.1)1-xAlxO2-yFy@LiAlO2 and a preparation method thereof, wherein x is more than 0, and y is less than or equal to 0.05, and the defects of LiNi0.8Mn0.1Co0.1O2 has poor electrochemical cycle performance and poor safety performance are overcome. Aluminum and fluorine are co-doped in a matrix material, and the trivalent aluminum element not only can stabilize the structure of the material, but also can prevent Ni<2+> from substituting Li<+>, so that the mixing of lithium / nickel cations is reduced, and fluorine can inhibit side reaction between the material and electrolyte; at the same time, the surface of a parent material Li(Ni0.8Co0.1Mn0.1)1-xAlxO2-yFy is coated with an extremely thin lithium fast ion conductor lithium metaaluminate which can enhance the lithium ion transport and reduce the surface alkalinity; the lithium ion battery cathode material can havehigher discharge specific capacity while improving cycling stability, and has a more stable structure compared with LiNi0.8Co0.1Mn0.1O2, the safety and processing performance of the material are improved, and especially at large magnification and high voltage, the safety performance is greatly improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

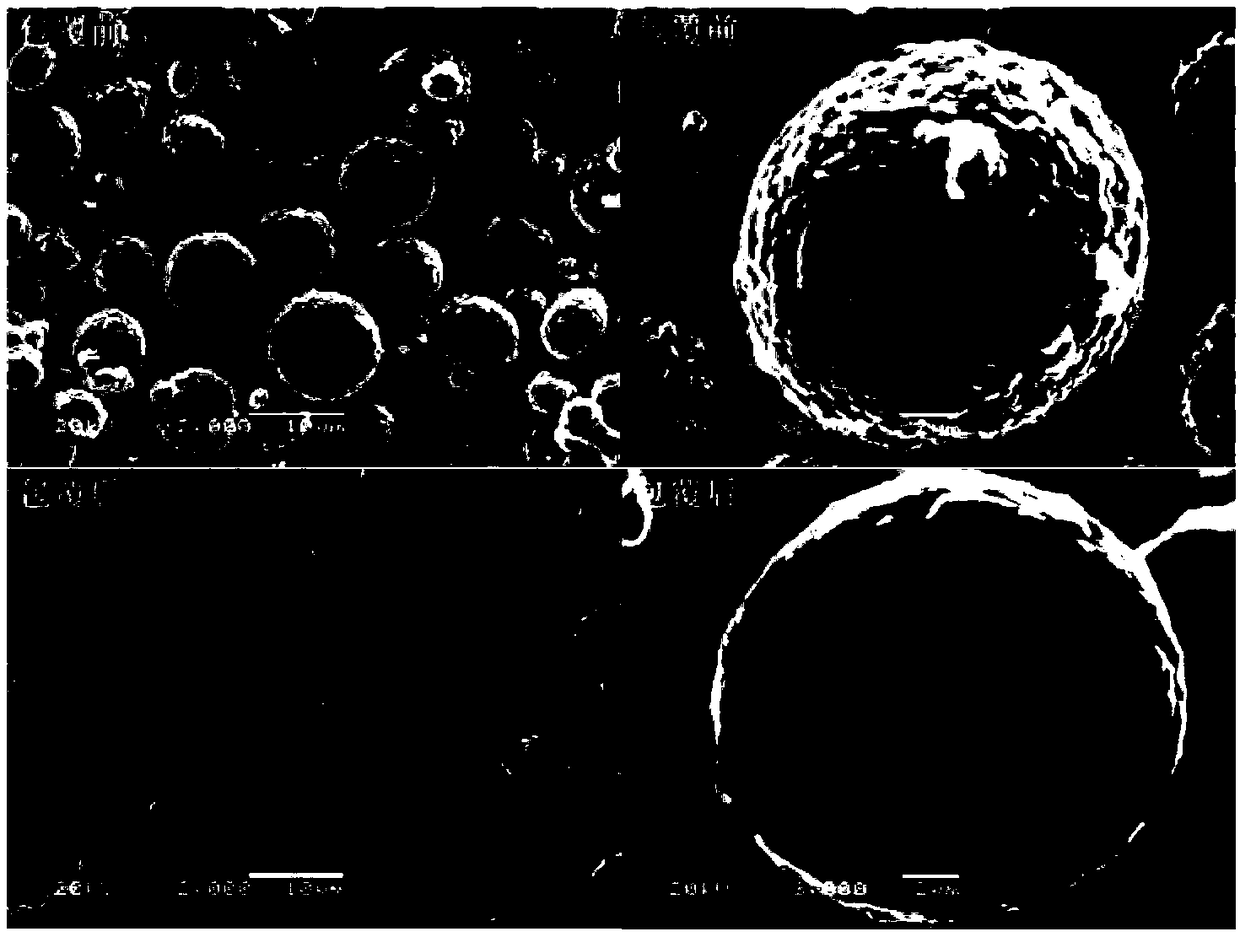

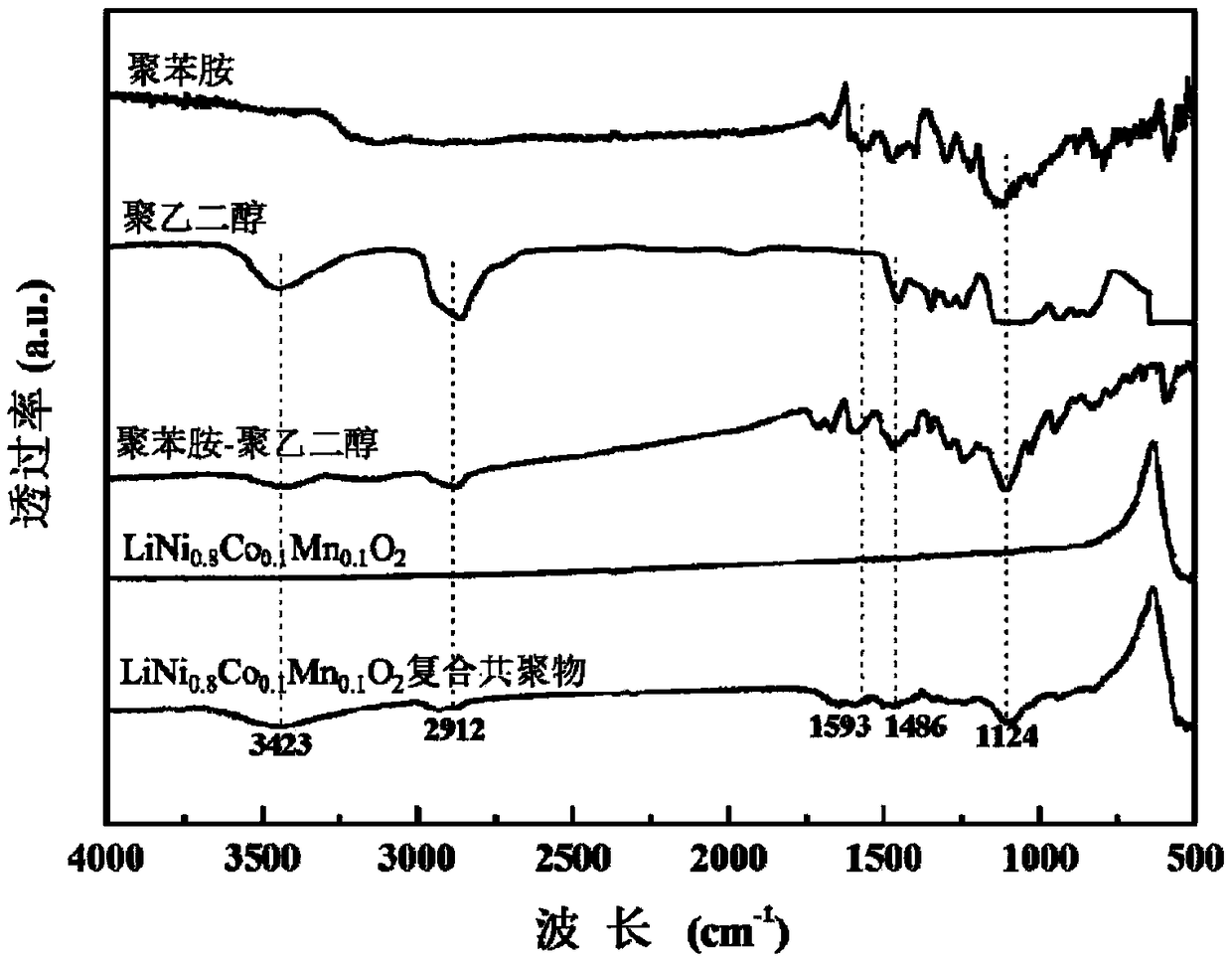

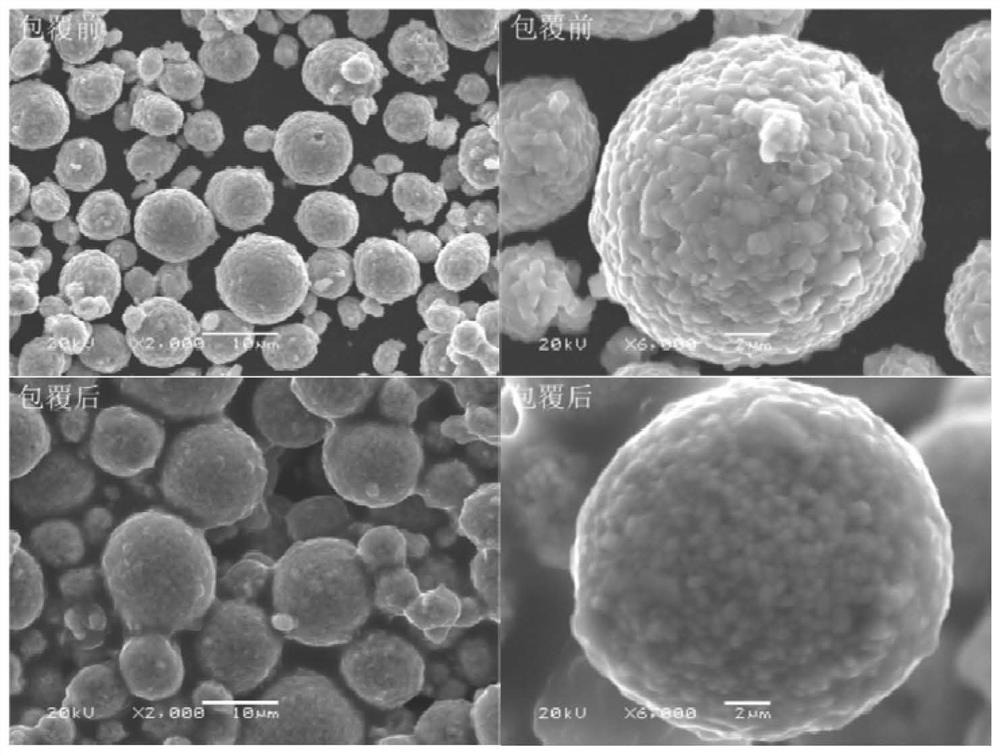

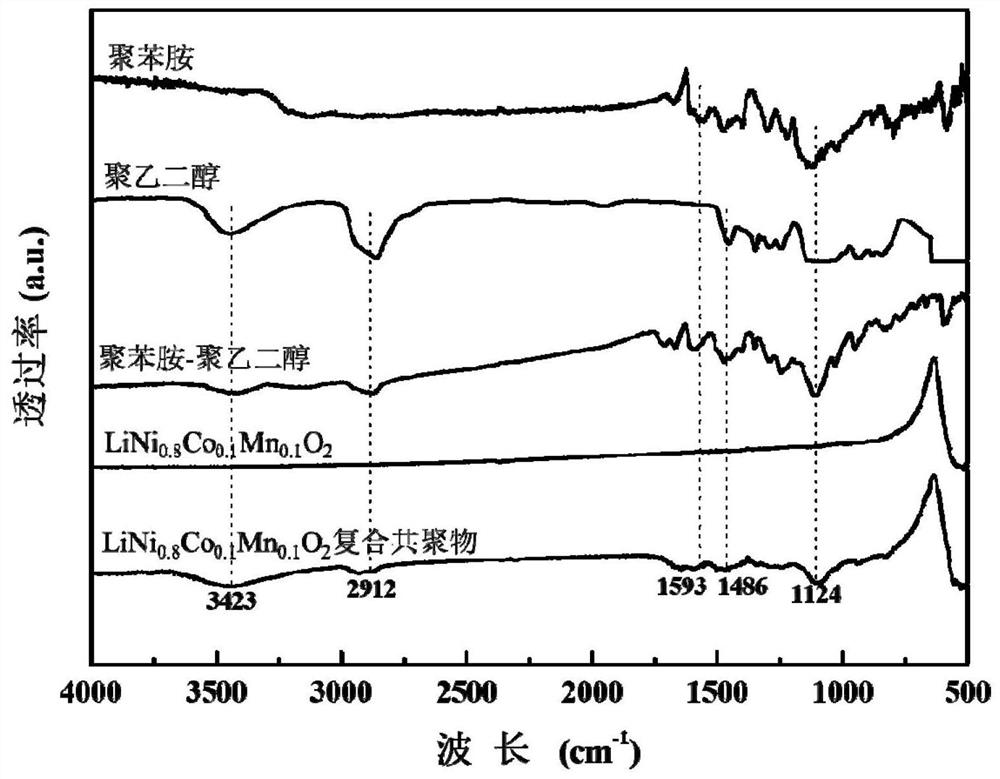

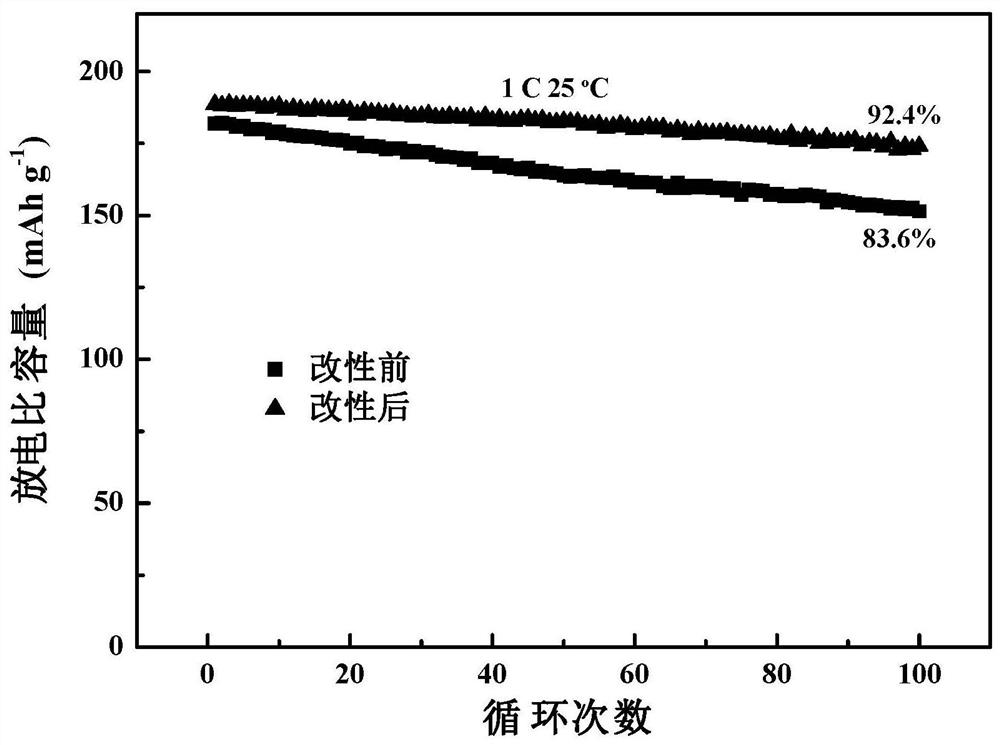

Polyaniline/polyethylene glycol-co-coated composite ternary positive electrode material and preparation and application thereof

ActiveCN108711613AImprove electrochemical performanceImprove the first irreversible capacityMaterial nanotechnologyCell electrodesPolyethylene glycolPolyaniline

The invention belongs to the technical field of positive electrode materials for lithium-ion batteries and particularly relates to a polyaniline / polyethylene glycol-co-coated composite ternary positive electrode material. The composite ternary positive electrode material comprises a ternary positive electrode material, polyaniline and polyethylene glycol, wherein the polyaniline and the polyethylene glycol coat the surface of the ternary positive electrode material. The invention further provides a preparation method and application of the composite ternary positive electrode material. According to the composite ternary positive electrode material, the electrical property of the obtained composite ternary positive electrode material is cooperatively improved through the surface action between the ternary positive electrode material and the polyaniline and the polyethylene glycol, and the coating effect and the chemical stability are improved. Furthermore, a wet coating method is innovatively adopted, so that the process is simple; the coating effect can be further improved through component cooperation; the performance of the material is improved; and the polyaniline / polyethylene glycol-co-coated composite ternary positive electrode material has the advantages of being simple in operation and high in consistency.

Owner:CENT SOUTH UNIV

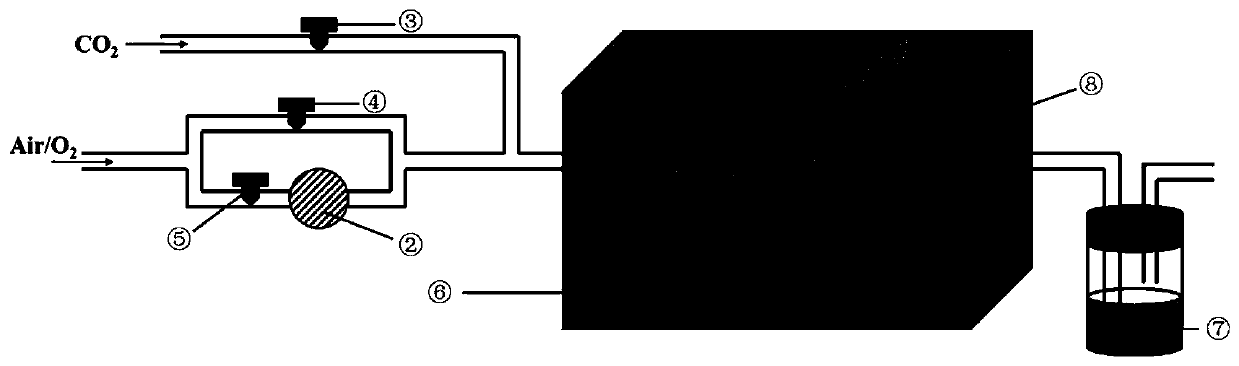

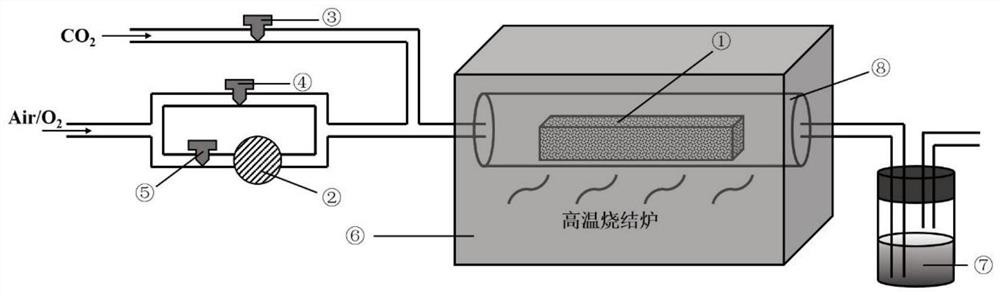

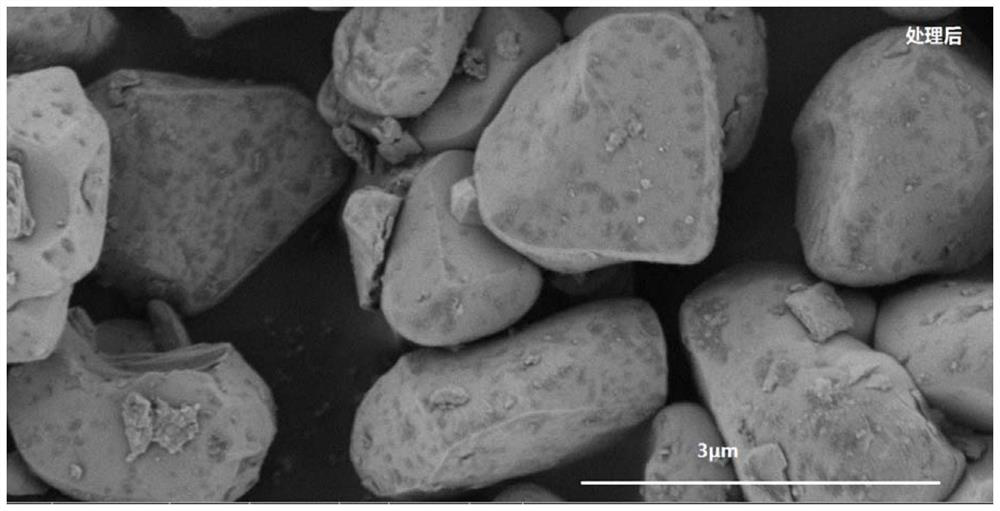

Treatment process for improving stability and conductivity of high-nickel positive electrode material

ActiveCN110350165AShorten the sintering timeIncrease production capacityCell electrodesSecondary cellsCarbon dioxidePlasma treatment

Owner:ZHEJIANG UNIV OF TECH +1

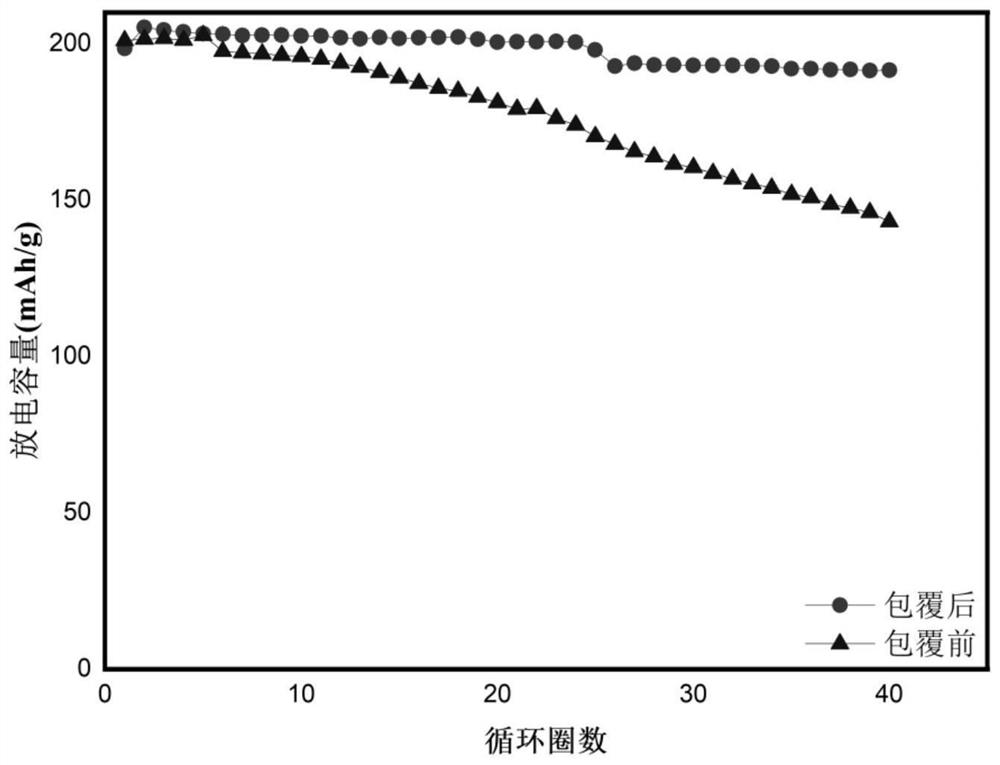

Composite high-nickel ternary positive electrode material and preparation method thereof

InactiveCN112164774AImprove cycle performanceImprove poor cycle stabilityCell electrodesSecondary cells servicing/maintenanceOxide coatingElectrode material

The invention discloses a composite high-nickel ternary positive electrode material and a preparation method thereof. The composite high-nickel ternary positive electrode material is composed of a high-nickel ternary positive electrode material, a metal oxide coating the surface of the high-nickel ternary positive electrode material and sulfonate coating the surface of the metal oxide. The problemthat the high-nickel ternary material is poor in cycling stability all the time is effectively solved, meanwhile, the coating treatment process is relatively simple, and the method is suitable for large-scale industrial production.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

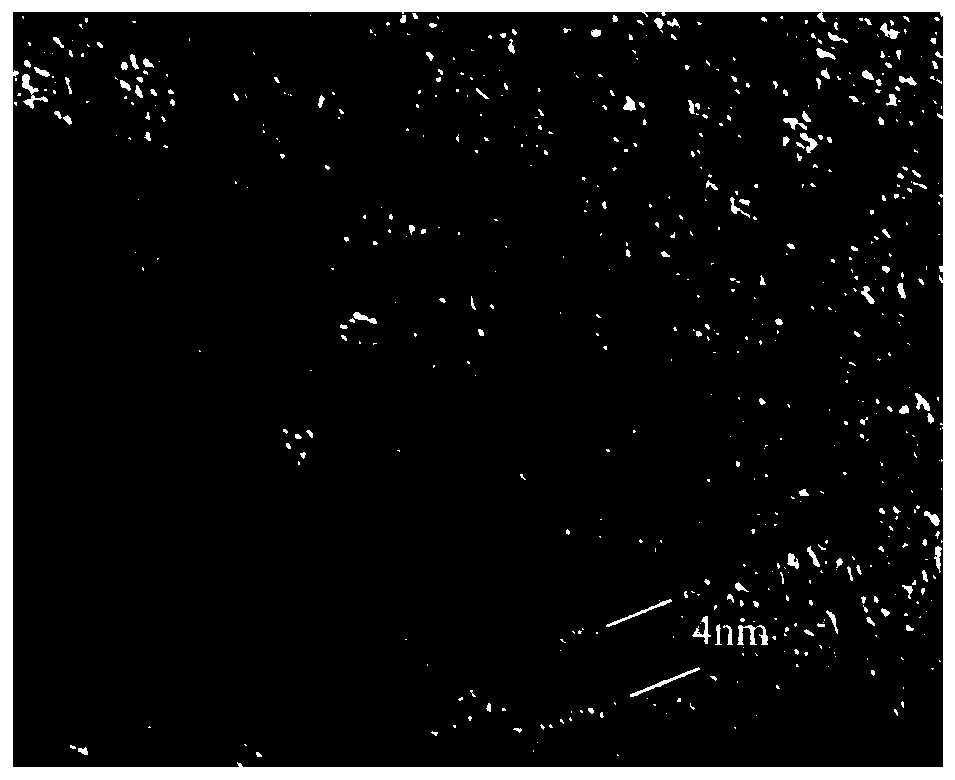

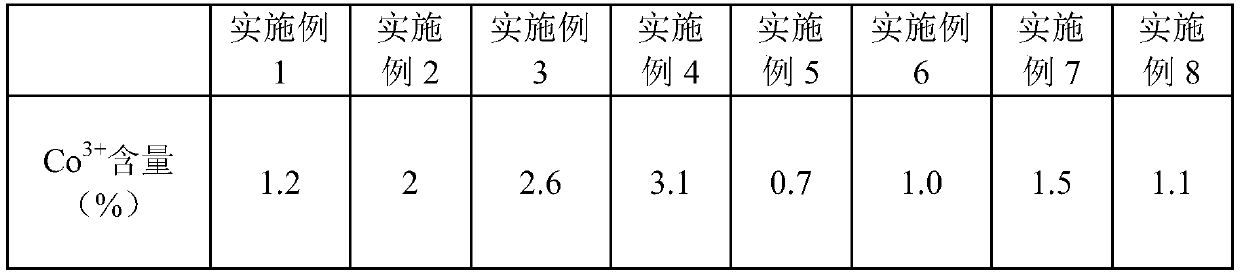

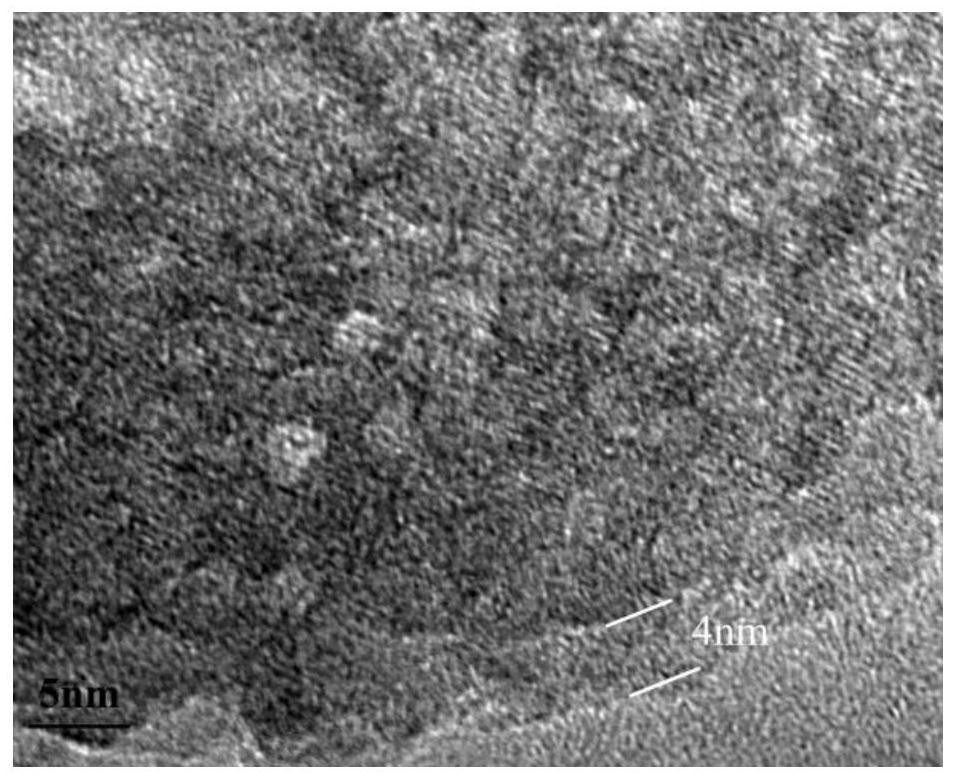

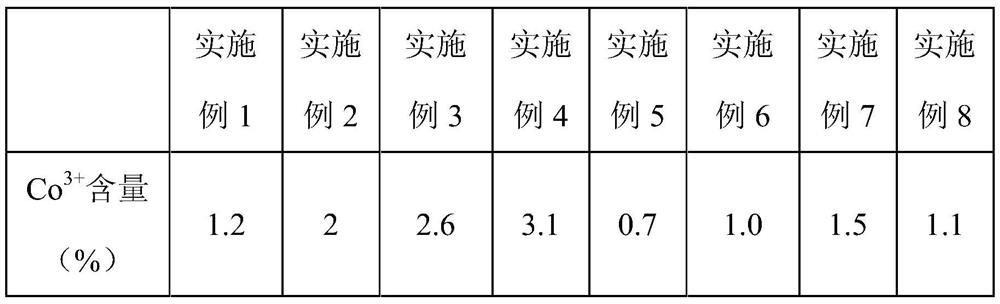

Preparation method of lithium cobalt oxide-coated high-nickel ternary material

ActiveCN110112404AUniform compositionThickness is easy to controlSecondary cellsPositive electrodesVacuum dryingCalcination

The invention provides a preparation method of a lithium cobalt oxide-coated high-nickel ternary material. The method comprises the following steps of: S1: taking and uniformly mixing a precursor of ahigh-nickel ternary material with an alkaline solution, and putting the mixture in a vacuum drying oven for drying to obtain mixed powder; S2: putting the dried mixed powder into an ozone oxidation reaction device, introducing ozone gases into the ozone oxidation reaction device, and performing stirring and oxidation; S3: washing the precursor in the step S2 by using hot deionized water, and drying the precursor after washing; and S4: uniformly mixing the dried precursor in the step S3 and a lithium source, and putting the mixture into a high-temperature furnace, performing temperature rise in an oxygen atmosphere in a sintering temperature from the room temperature to a sintering temperature, performing heat preservation, and performing natural cooling after heat preservation to obtain alithium cobalt oxide-coated high-nickel ternary material. The method employs the ozone oxidation method to perform oxidation for the Co2+ at the surface of the precursor to allow the surface of the precursor to generate structural recombination to generate a layer of CoOOH, and the precursor with the CoOOH at the surface is mixed with the lithium source for high-temperature calcinations to obtaina CoOOH-coated high-nickel ternary material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A polyaniline/polyethylene glycol co-wrapped composite ternary cathode material and its preparation and application

ActiveCN108711613BUniform coating modificationImprove the first irreversible capacityMaterial nanotechnologyCell electrodesElectrical batteryPolyethylene glycol

The invention belongs to the technical field of positive electrode materials for lithium-ion batteries and particularly relates to a polyaniline / polyethylene glycol-co-coated composite ternary positive electrode material. The composite ternary positive electrode material comprises a ternary positive electrode material, polyaniline and polyethylene glycol, wherein the polyaniline and the polyethylene glycol coat the surface of the ternary positive electrode material. The invention further provides a preparation method and application of the composite ternary positive electrode material. According to the composite ternary positive electrode material, the electrical property of the obtained composite ternary positive electrode material is cooperatively improved through the surface action between the ternary positive electrode material and the polyaniline and the polyethylene glycol, and the coating effect and the chemical stability are improved. Furthermore, a wet coating method is innovatively adopted, so that the process is simple; the coating effect can be further improved through component cooperation; the performance of the material is improved; and the polyaniline / polyethylene glycol-co-coated composite ternary positive electrode material has the advantages of being simple in operation and high in consistency.

Owner:CENT SOUTH UNIV

Positive electrode material and preparation method and application thereof

ActiveCN114267817AImproved magnification performanceImprove cycle performanceLi-accumulatorsNon-aqueous electrolyte accumulator electrodesElectrical batteryElectrode material

The invention relates to the technical field of batteries, in particular to a positive electrode material and a preparation method and application thereof. The positive electrode material comprises a positive electrode base material, and a first coating layer and a second coating layer which are sequentially coated on the surface of the positive electrode base material from inside to outside, the positive electrode base material comprises a positive electrode active material and cobalt oxide attached to a part of the surface of the positive electrode active material, the chemical general formula of the positive electrode active material comprises LiNi < 0.9 > Co < 0.05 > Mn < 0.05-x-y > In < x > SbyO < 2 >, xlt; 0, 0.05, olt; yt; Yt; 0.05 of the total weight; the first coating layer comprises a strontium element, and the second coating layer comprises a boron element. The positive electrode material disclosed by the invention has excellent rate capability, cycle performance and safety performance.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

High-nickel ternary material, surface modification method and lithium ion battery

ActiveCN112086679AStable structureAvoid the problem of poor electrochemical performanceElectrode thermal treatmentSecondary cells servicing/maintenanceLithium-ion batteryBattery cell

The invention discloses a high-nickel ternary material, a surface modification method and a lithium ion battery. The surface modification method comprises the following steps: firstly introducing soluble salt of cation Li+ as a first additive in the washing process, and then introducing a TiOSO4 acid solution, wherein the third additive is an Al2(SO4)3 acid solution, and the fourth additive is a NaAlO2 alkaline solution; and finally performing separating, drying and calcining to obtain the surface-modified high-nickel ternary material. The high-nickel ternary material obtained by the surface modification method can effectively reduce the residual alkali on the surface of the high-nickel ternary material and improve the structural stability.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

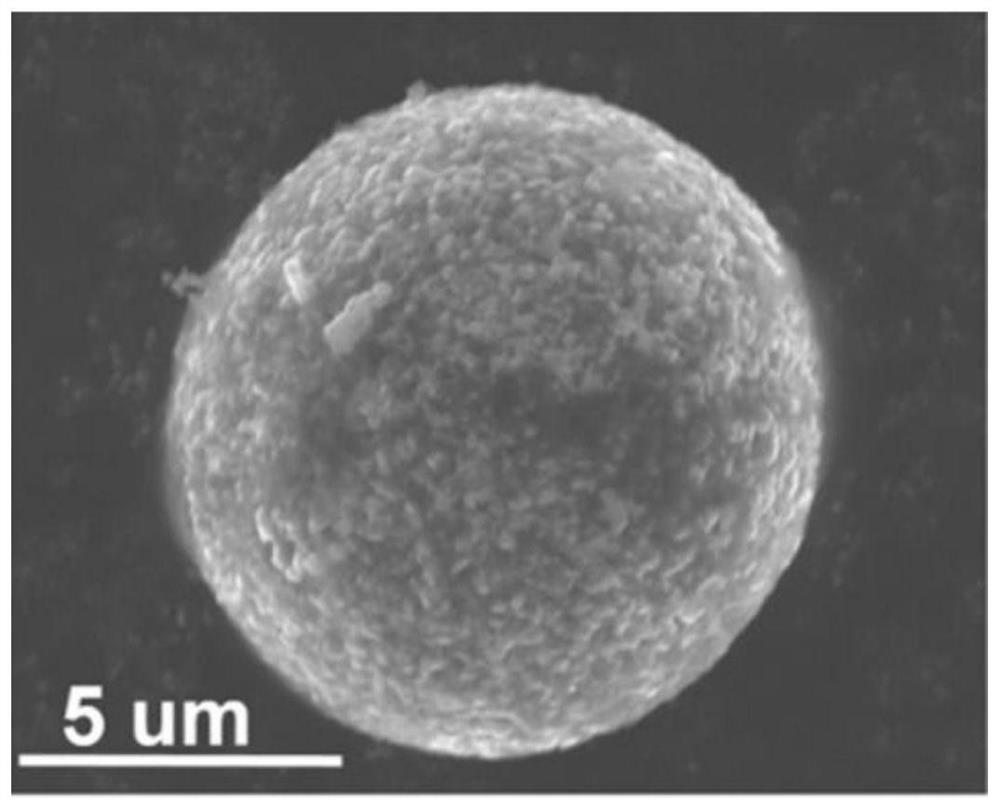

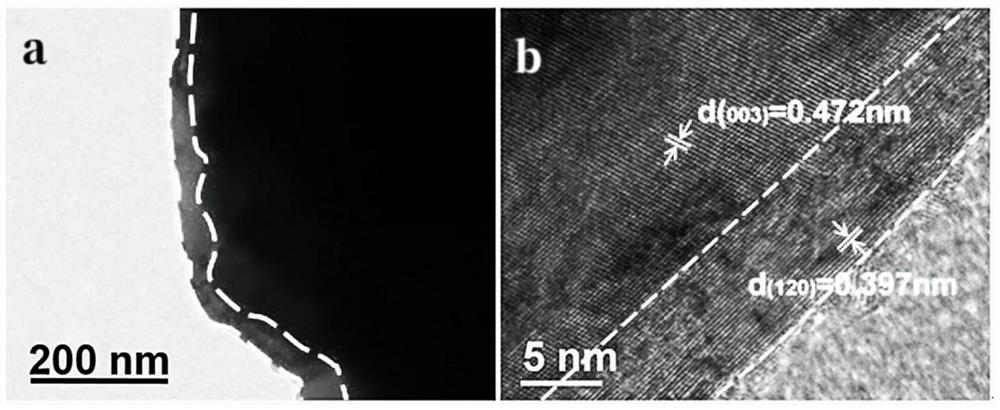

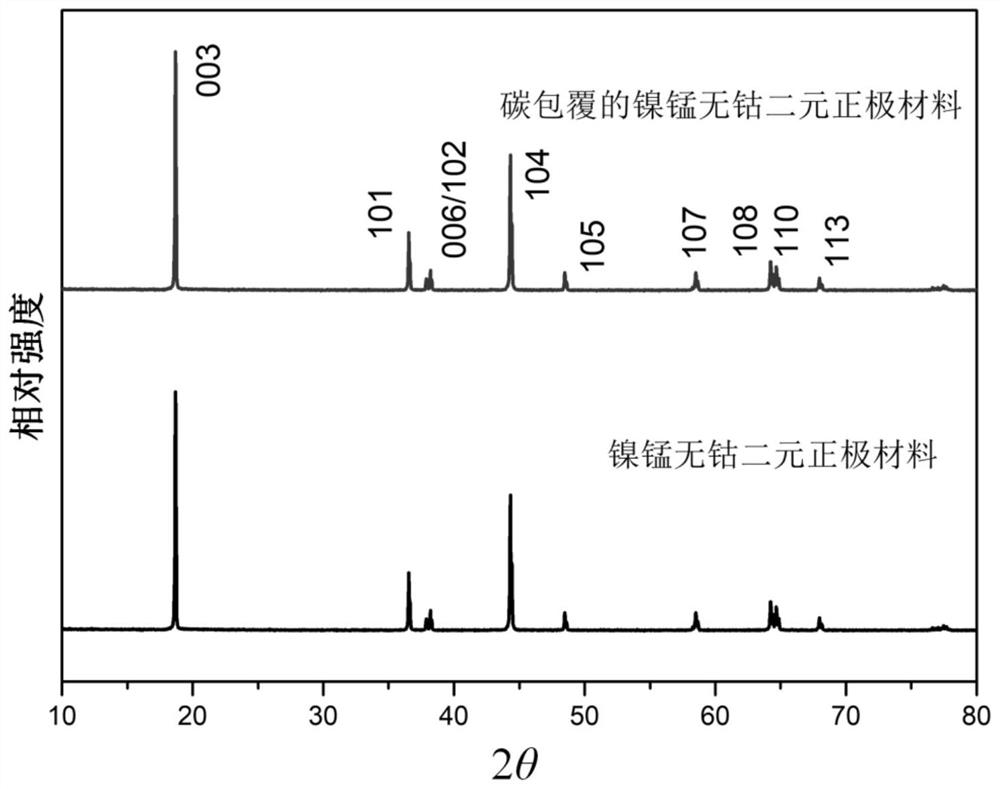

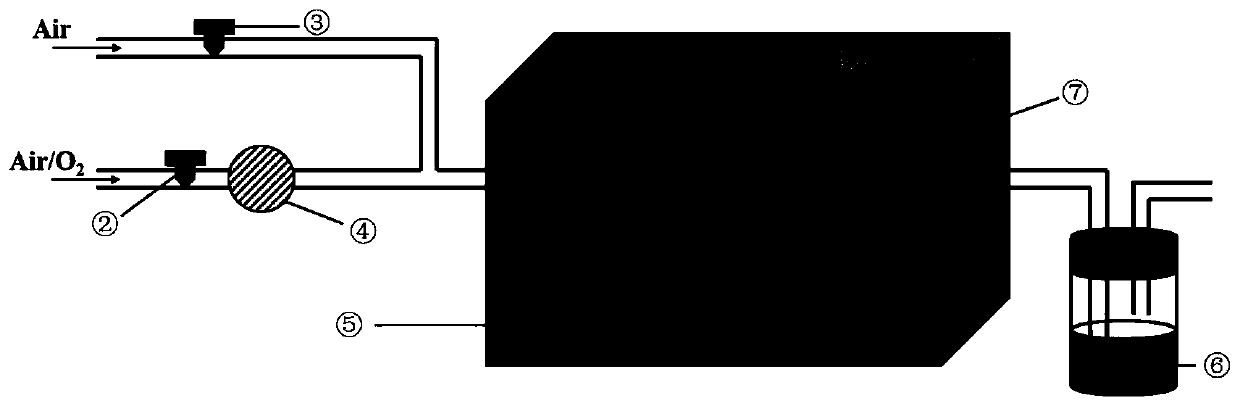

Carbon-coated nickel-manganese binary cobalt-free positive electrode material, preparation method thereof and lithium ion battery

ActiveCN113666432AImprove structural stabilityReduce uniformityGrapheneSecondary cellsCarbon coatingManganese

The invention provides a carbon-coated nickel-manganese binary cobalt-free positive electrode material, a preparation method thereof and a lithium ion battery. The preparation method comprises the steps of enabling an ion replacement matrix, graphene and a solvent to be subjected to a solvothermal reaction, wherein the ion replacement matrix adopts a general formula MOn or M (OH) n, a solution containing the hydroxide / graphene composite material is obtained, the Ksp of hydroxide is (1 * 10 <-40 >)-(1 * 10 <-11 >), M is selected from the IIA group, the IIIA group, the IVA group, the IIIB group, the IVB group, the VIB group, the VIIB group or the VIII group, and n is 2-4; and carrying out ion exchange on the nickel-manganese binary cobalt-free positive electrode material and the solution containing the hydroxide / graphene composite material to obtain the carbon-coated nickel-manganese binary cobalt-free positive electrode material. By adopting the preparation method, a compact and stable carbon coating layer can be formed on the surface of the nickel-manganese binary cobalt-free positive electrode material.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

Preparation technology capable of improving cycle performance and electrical conductivity of high-nickel positive electrode material

ActiveCN110350167AShort sintering timeIncrease production capacitySecondary cellsPositive electrodesAir atmosphereCarbon film

The invention provides a preparation technology capable of improving the cycle performance and the electrical conductivity of a high-nickel positive electrode material. The preparation technology comprises the steps of mixing a high-nickel positive electrode material precursor with a lithium salt evenly at a certain ratio; sintering in ozone-containing oxygen or air atmosphere; and carrying out carbon dioxide plasma processing after sintering is ended. According to the method, the sintering time of the material ca be shortened, the productivity is improved, the amount of a gas is reduced, thecost is reduced, the lithium-nickel mixed discharge degree of the high-nickel positive electrode material is reduced and the consistency and the stability of the material are improved; carbon dioxideplasma processing is carried out after sintering is ended, so that the residual alkali content on the surface can be reduced; and a carbon film can be formed on the surface, so that the electrical conductivity and the rate capability of the material are improved.

Owner:ZHEJIANG UNIV OF TECH +1

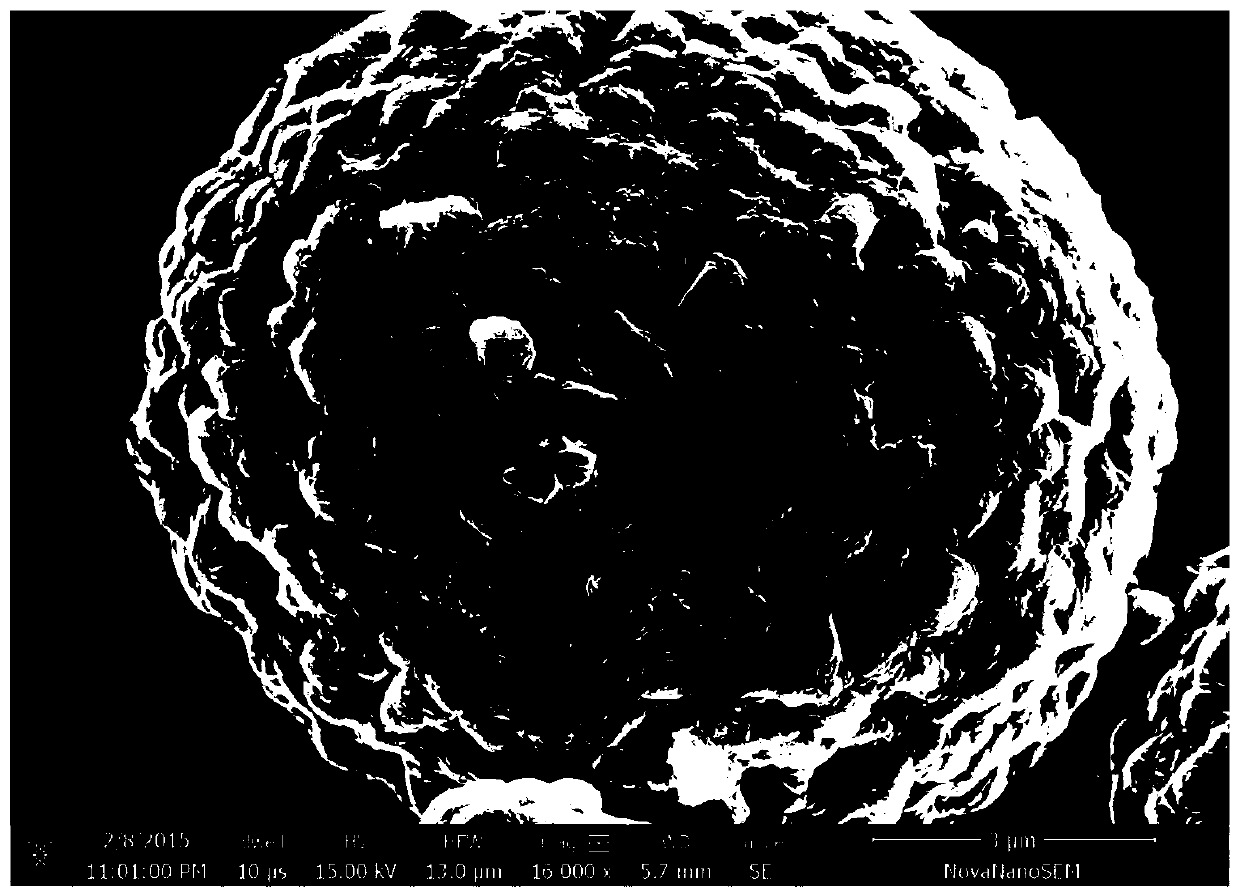

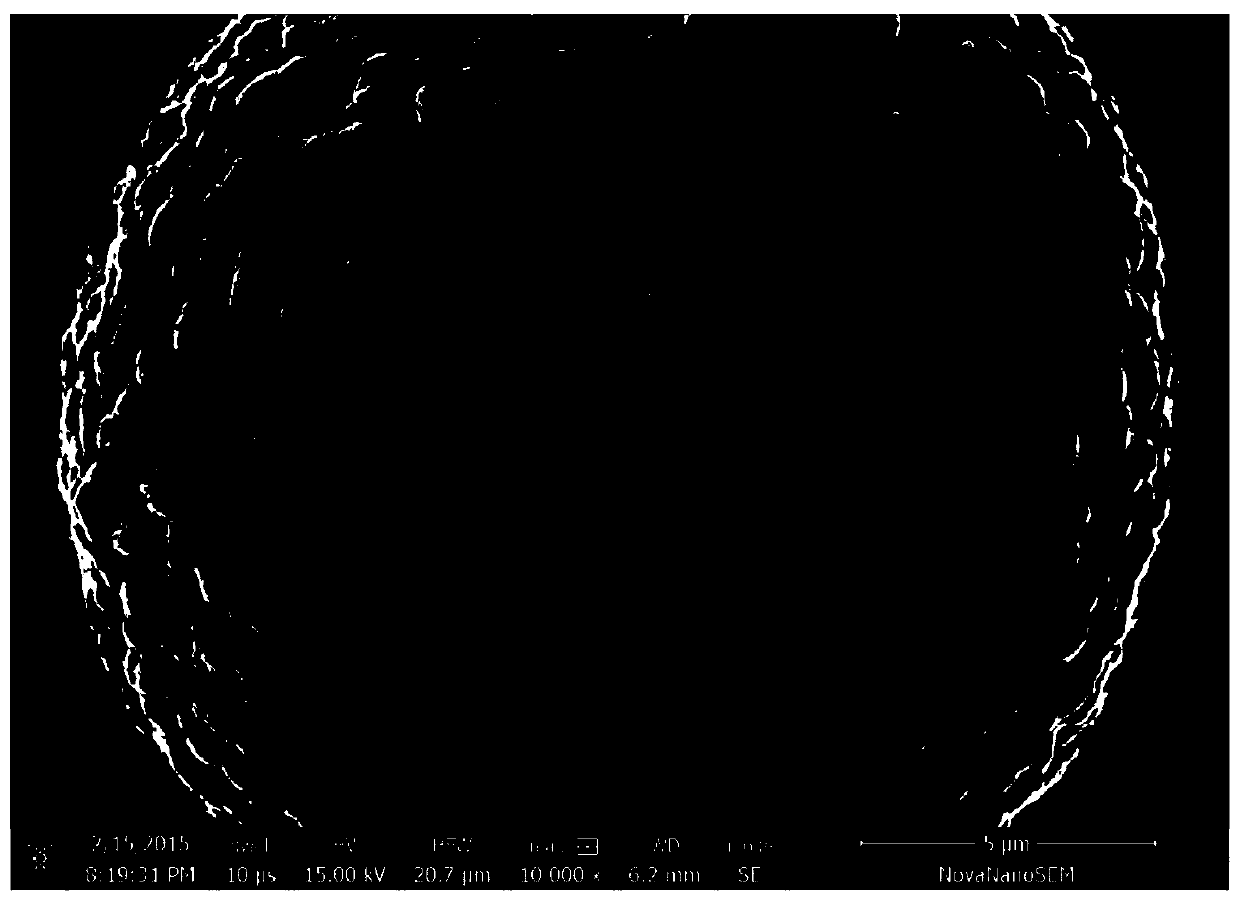

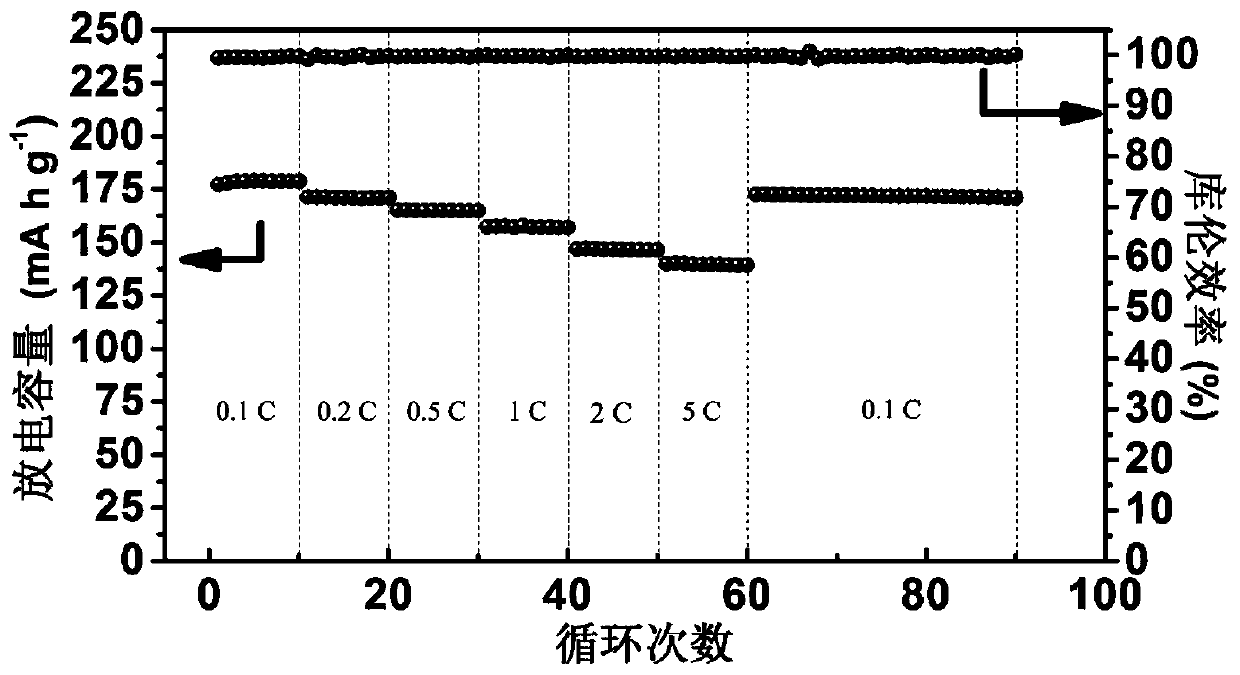

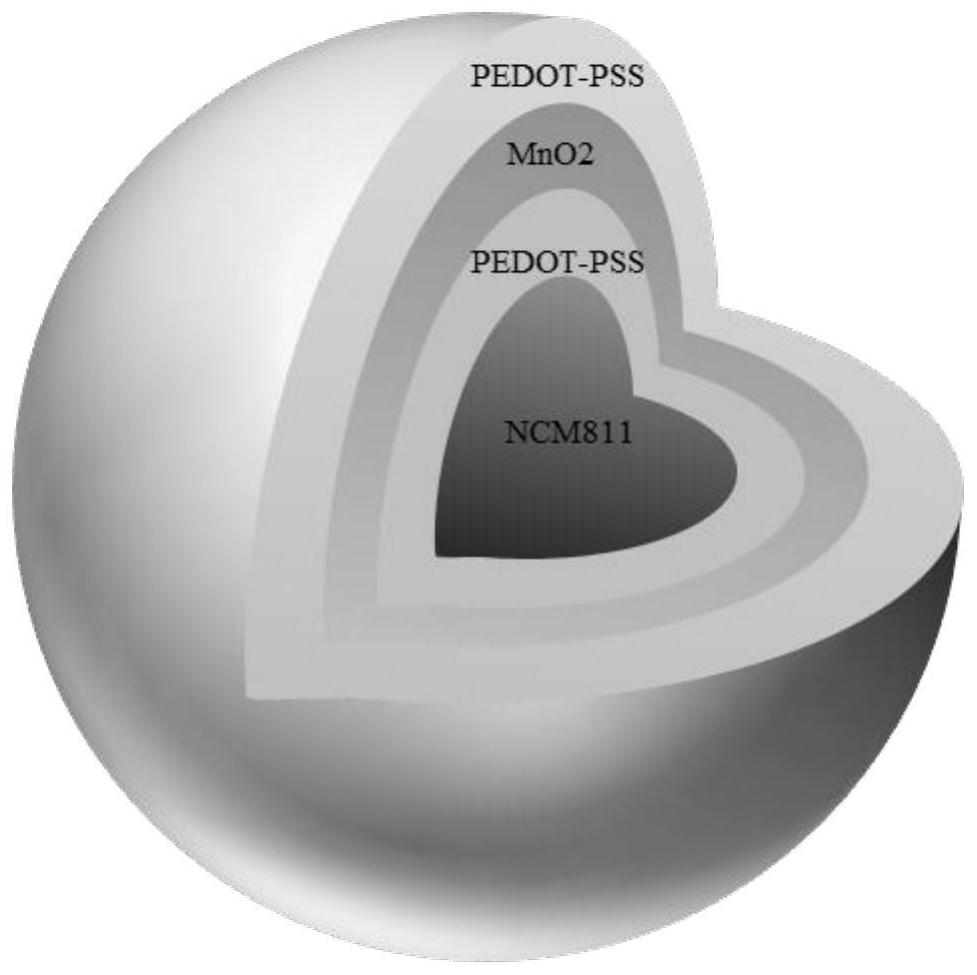

Conductive polymer and transition metal oxide coated high-nickel positive electrode material and method

ActiveCN112758994BResidue reductionReduce transmissionMaterial nanotechnologyElectrolysis componentsConductive polymerPolystyrene

The invention provides a high-nickel positive electrode material coated with a conductive polymer and a transition metal oxide and a preparation method thereof. The center layer is a spherical high-nickel ternary material, and the surface of the center layer is a cladding layer, and the cladding layers are sequentially arranged from the inside to the outside. Poly(3,4‑ethylenedioxythiophene / polystyrene sulfonate PEDOT‑PSS, MnO 2 , the three-layer structure of poly 3,4-ethylenedioxythiophene / polystyrene sulfonate PEDOT-PSS, the chemical formula of the high-nickel ternary material is Li z Ni x co y mn 1‑x‑y o 2 , where 0.75≤x≤0.85, 0.075≤y≤0.125, 1.0≤z≤1.1. The invention has higher discharge capacity, better cycle stability and rate performance, and the surface coating layer can effectively reduce the residual amount of lithium ions on the surface of the cathode material, thereby greatly inhibiting the propagation of LiF and HF during the cycle process, Thereby reducing the dissolution of transition metal ions and the formation of cycle electrode cracks.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

A kind of preparation method of high-nickel ternary material coated with lithium cobalt oxide

ActiveCN110112404BUniform compositionThickness is easy to controlSecondary cellsPositive electrodesLithiumPhysical chemistry

The invention provides a preparation method of a lithium cobalt oxide-coated high-nickel ternary material. The method comprises the following steps of: S1: taking and uniformly mixing a precursor of ahigh-nickel ternary material with an alkaline solution, and putting the mixture in a vacuum drying oven for drying to obtain mixed powder; S2: putting the dried mixed powder into an ozone oxidation reaction device, introducing ozone gases into the ozone oxidation reaction device, and performing stirring and oxidation; S3: washing the precursor in the step S2 by using hot deionized water, and drying the precursor after washing; and S4: uniformly mixing the dried precursor in the step S3 and a lithium source, and putting the mixture into a high-temperature furnace, performing temperature rise in an oxygen atmosphere in a sintering temperature from the room temperature to a sintering temperature, performing heat preservation, and performing natural cooling after heat preservation to obtain alithium cobalt oxide-coated high-nickel ternary material. The method employs the ozone oxidation method to perform oxidation for the Co2+ at the surface of the precursor to allow the surface of the precursor to generate structural recombination to generate a layer of CoOOH, and the precursor with the CoOOH at the surface is mixed with the lithium source for high-temperature calcinations to obtaina CoOOH-coated high-nickel ternary material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A treatment process to improve the stability and conductivity of high-nickel cathode materials

ActiveCN110350165BShort sintering timeImprove consistencyCell electrodesSecondary cellsCarbon layerMetallurgy

The invention provides a treatment process for improving the stability and conductivity of a high-nickel positive electrode material, and carbon dioxide annealing treatment and carbon dioxide plasma treatment are respectively performed on the high-nickel positive electrode material obtained by sintering in an ozone atmosphere. The method can not only shorten the sintering time of materials, increase production capacity, reduce the amount of gas, and reduce costs, but also can reduce the degree of lithium-nickel mixing of high-nickel cathode materials, improve the consistency and stability of materials, and prolong the service life of batteries; After the sintering, carbon dioxide gas is continuously introduced for annealing treatment, which can react with the residual lithium hydroxide on the surface of the high-nickel cathode material, reduce the residual alkali content on the surface of the material, reduce the sensitivity of the material to air, prolong the storage time of the material, and improve the The processing performance of the material; finally, carbon dioxide plasma treatment is performed to coat a carbon layer on the surface of the material to increase the electrical conductivity of the material, thereby improving the rate performance of the material.

Owner:ZHEJIANG UNIV OF TECH +1

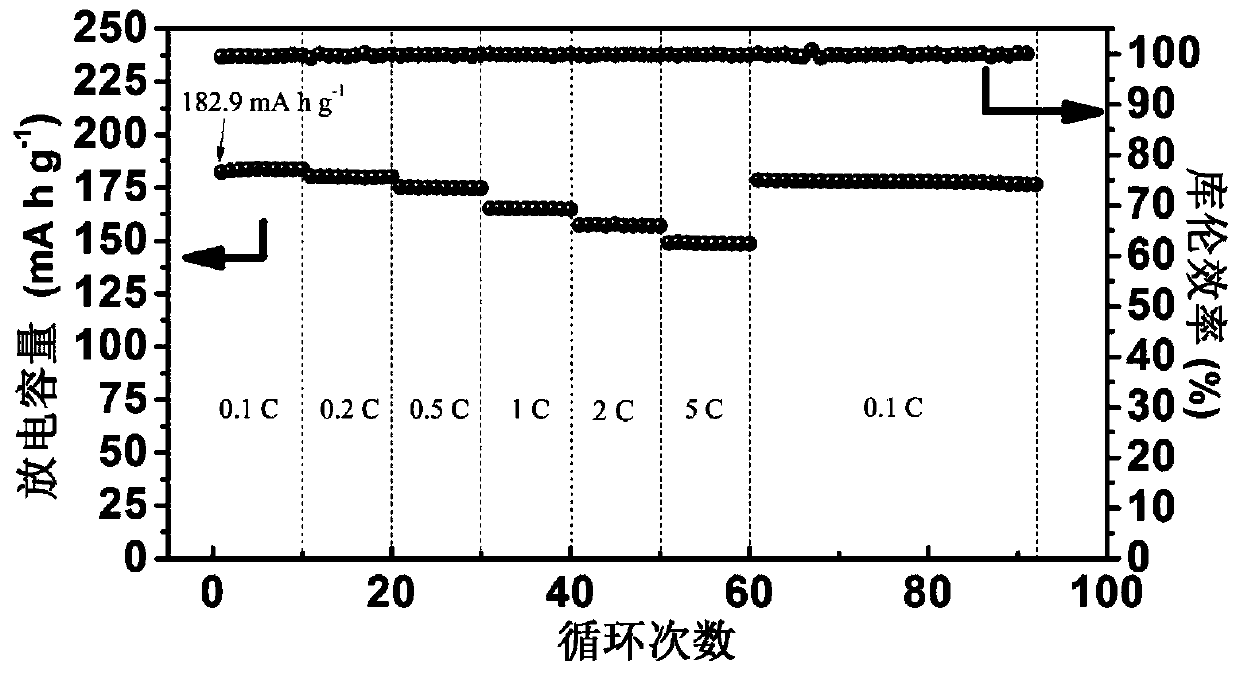

Ternary positive electrode material of lithium ion battery and preparation method and application thereof

InactiveCN110808370ASimple processReduce manufacturing costsSecondary cellsPositive electrodesPhysical chemistryLithium-ion battery

The invention provides a ternary positive electrode material of a lithium ion battery and a preparation method and application thereof. The chemical general formula of the ternary positive electrode material of the lithium ion battery is LiNi1-x-yCoxMnyMaFbO2, wherein x is larger than 0.1 and smaller than 0.3, y is larger than 0.1 and smaller than 0.3, a is larger than 0.01 and smaller than 0.1, and b is larger than 0.01 and smaller than 0.05; and M is selected from one of Ga, Zn, Na and Al. The ternary positive electrode material of the lithium ion battery has excellent cycling stability andhigh-quality specific capacity, and the lithium ion battery prepared by applying the ternary positive electrode material to the lithium ion battery has the advantages of high capacity, good cycling stability and long service life.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of positive electrode material of lithium ion battery and preparation method thereof

ActiveCN107394160BImprove surface structureReduce surface residual alkali contentMaterial nanotechnologyCell electrodesCrystal structureLithium-ion battery

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

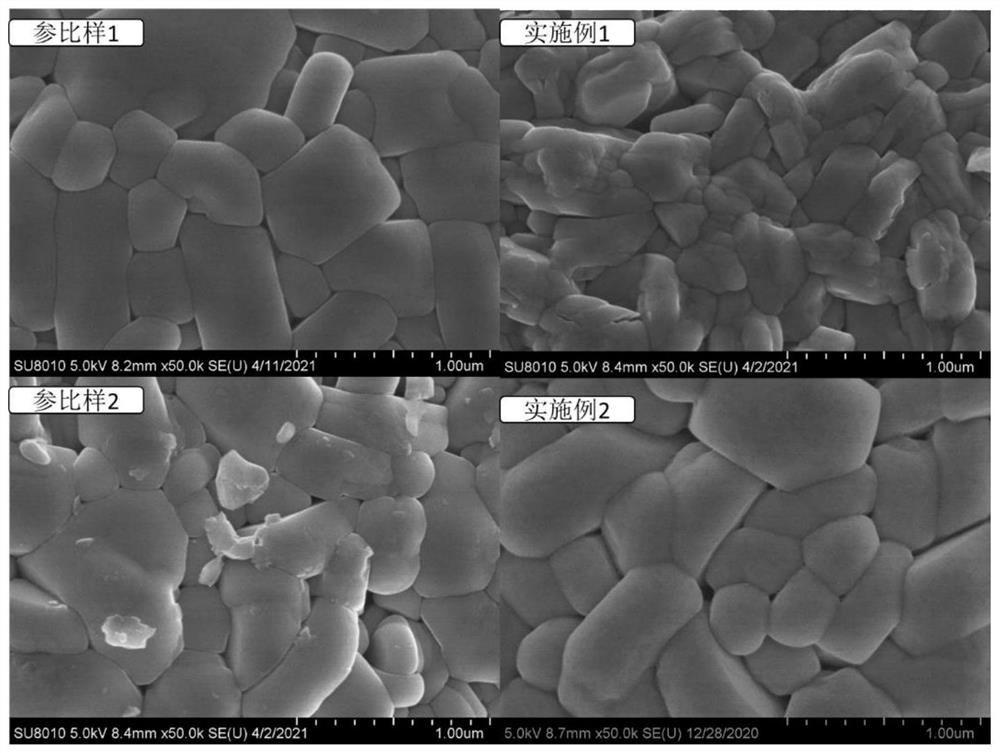

Interface composite modification method of positive electrode material, positive electrode material and application

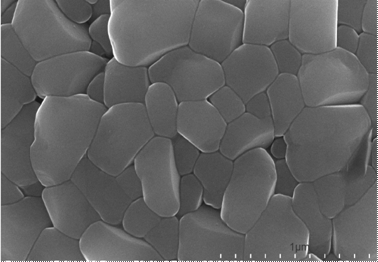

ActiveCN114014381AReduce surface residual alkali contentImprove cycle stabilityPositive electrodesLi-accumulatorsHeat stabilitySingle crystal

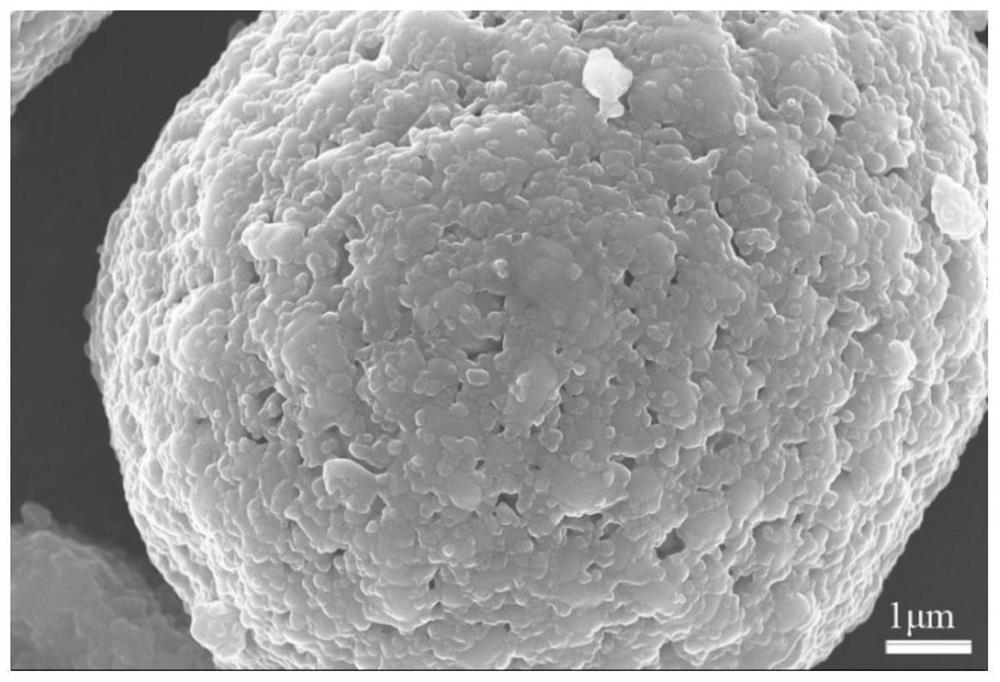

The invention provides an interface composite modification method of a positive electrode material, the positive electrode material and application, and the interface composite modification method comprises the following steps: mixing a precursor, a lithium source and a nano oxide for the first time, conducting calcining to obtain a sintered material, mixing the sintered material, an inducer and a boron source for the second time, and conducting calcining to obtain a single crystal positive electrode material. According to the interface composite modification method provided by the invention, the content of residual alkali on the surface of the positive electrode material is reduced in a co-coating manner, so that the cycling stability, the rate capability and the thermal stability of the positive electrode material are improved.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

A kind of double modified high nickel ternary material and preparation method thereof

ActiveCN112750991BReduce surface activityImprove cycle performanceSecondary cellsPositive electrodesElectrical batteryLithium-ion battery

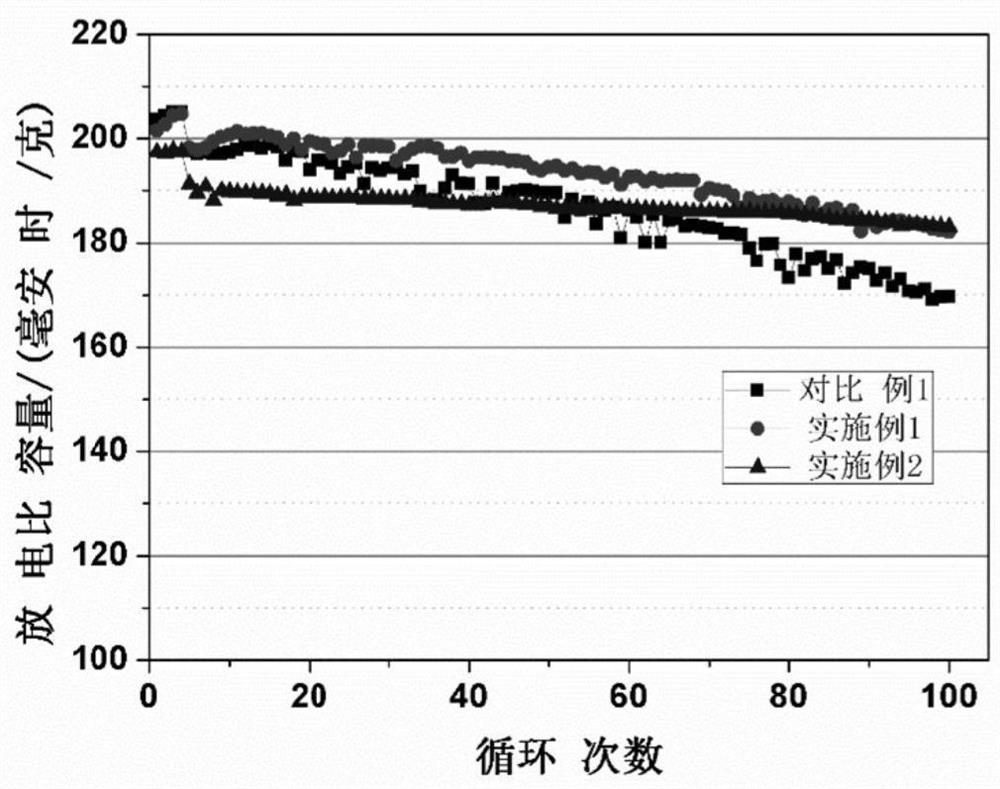

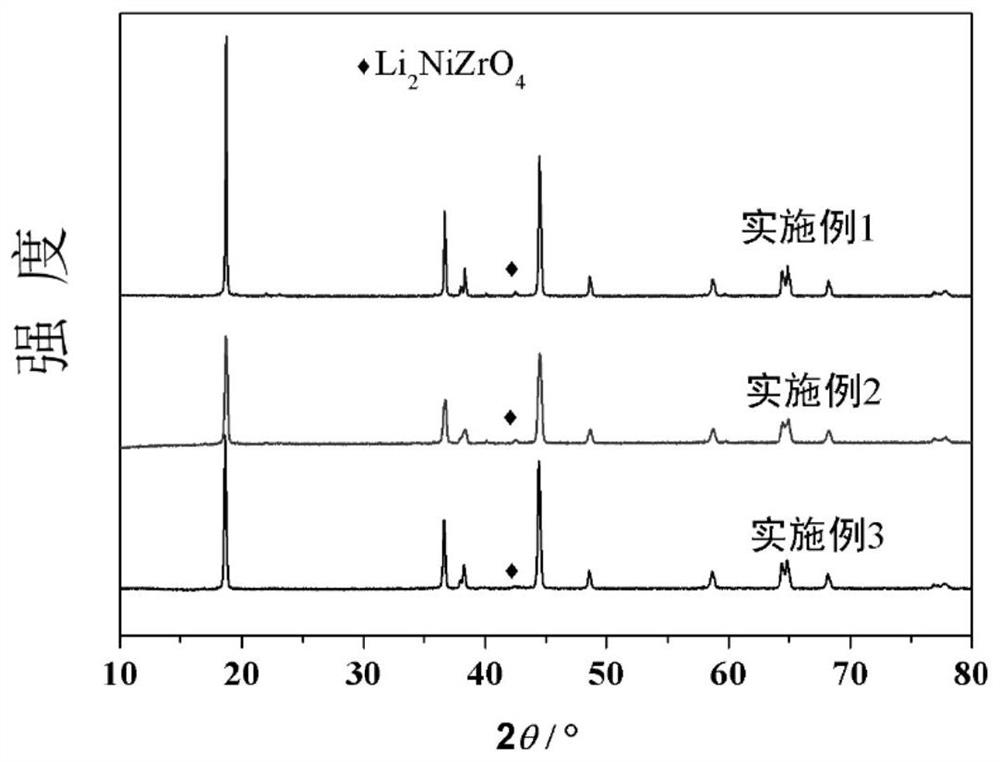

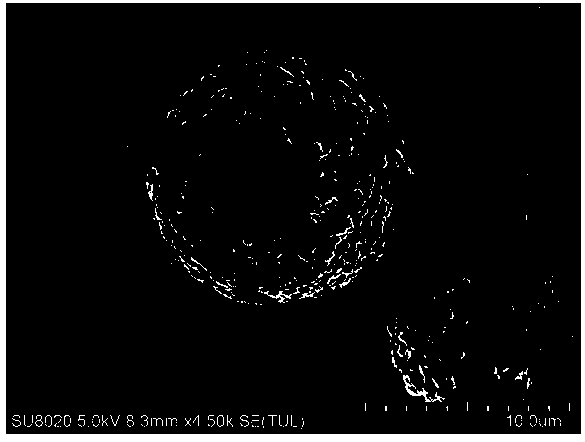

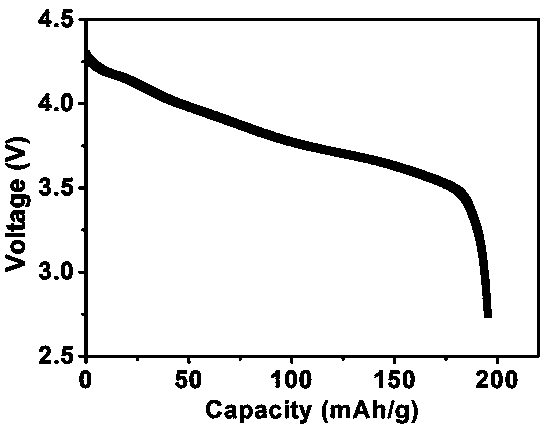

The invention belongs to the field of positive electrode materials for lithium ion batteries, and discloses a double-modified high-nickel ternary material and a preparation method thereof. The method includes: (1) first calcining a mixture containing a high-nickel ternary precursor and a lithium salt to obtain a high-nickel ternary base material; (2) mixing the high-nickel ternary base material with nano-ZrO 2 mixed to obtain ZrO 2 Coated high nickel ternary material; (3) the ZrO 2 The coated high-nickel ternary material is subjected to a second calcination to obtain Li 2 NiZrO 4 Double-modified high-nickel ternary materials with cladding and subsurface doping of Zr. The method provided by the invention effectively reduces the surface activity of the ternary material, thereby reducing the residual alkali content on the surface of the material and improving the cycle performance of the ternary material.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of high rate nickel cobalt lithium aluminate cathode material

ActiveCN107093741BImprove performanceImprove cycle performanceCell electrodesSecondary cellsCyclic processHigh rate

The invention discloses a method for preparing a high-rate nickel cobalt lithium aluminate anode material. The method comprises the following steps: (1) preparing a nickel cobalt lithium aluminate precursor; (2) performing lithium-site doping and modifying on potassium ions; and (3) constructing a cladding layer of a lithium-containing compound. According to the method, the dispersing speed of lithium ions is effectively increased by lithium-site replacement of potassium ions, and the rate capability of a material can be improved; the lithium-containing compound layer constructed on the material surface can be used for reducing the content of alkali remained on the material surface and reduce later cell bubbling; side reaction can be effectively inhibited, and the material structure stability in the cycling process can be promoted; and the lithium-containing compound layer has high conducting performance for lithium ions, embedding and separating of lithium ions can be accelerated, the problem of poor lithium ion conductivity when conventional metal oxide is used as the cladding layer can be solved, and the cycling performance and rate performance of the material can be improved.

Owner:郑州中科新兴产业技术研究院

A kind of lithium-ion battery layered cathode material and preparation method thereof

ActiveCN107994212BStable crystal structureReduce surface residual alkali contentSecondary cellsPositive electrodesElectrical batteryManganese

The invention discloses a layered positive electrode material for a lithium-ion battery. The layered positive electrode material comprises a body and a B2O3 coating layer, wherein a chemical formula of the body is Li<x>(NiCoMn<c>)<1-y>M<y>O<2>, wherein x is smaller than or equal to 1.04 and greater than or equal to 0.96, y is smaller than or equal to 0.06 and greater than or equal to 0.01, ais smaller than or equal to 0.9 and greater than or equal to 0.8, a+b+c is equal to 1, and M is selected from at least one of an Al element, a Mg element, a Ti element and a Zr element. The inventionfurther discloses a preparation method of the layered positive electrode material for the lithium-ion battery. The method comprises the following steps of mixing a nickel-cobalt manganese hydroxide,a lithium source and a nano oxide additive evenly and carrying out first sintering to obtain unmodified powder; stirring the unmodified powder and water, carrying out centrifugal separation to obtaina solid material, drying and crushing to obtain washing powder; adding LIBOB to an organic solvent for dissolving, adding the washing powder for mixing, stirring, evaporating and carrying out second sintering to obtain the layered positive electrode material for the lithium-ion battery.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of high-nickel positive electrode material and preparation method thereof

ActiveCN109742376BLower pHGuaranteed cycle performanceMaterial nanotechnologyCell electrodesInorganic saltsPhysical chemistry

The invention discloses a high-nickel positive electrode material and a preparation method thereof. The base material of the high-nickel positive electrode material is Li x (Ni a co b mn c )O 2 Type NCM ternary material, wherein 1.0≤x≤1.06, a+b+c=1, a≥0.8, characterized in that the base material is coated with a surface-modified nano-metal oxide passivation layer , the substance used in the surface modification is a low melting point inorganic salt. The base material is covered with a layer of nano-metal oxide passivation layer modified by low-melting point inorganic salt surface. In the ternary system with increased nickel content, the surface modification is completed by two annealing treatments to stabilize the high-nickel cathode material. crystal structure and reduce the residual alkali content on the surface of the material, the prepared high-nickel cathode material has high capacity and good cycle.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

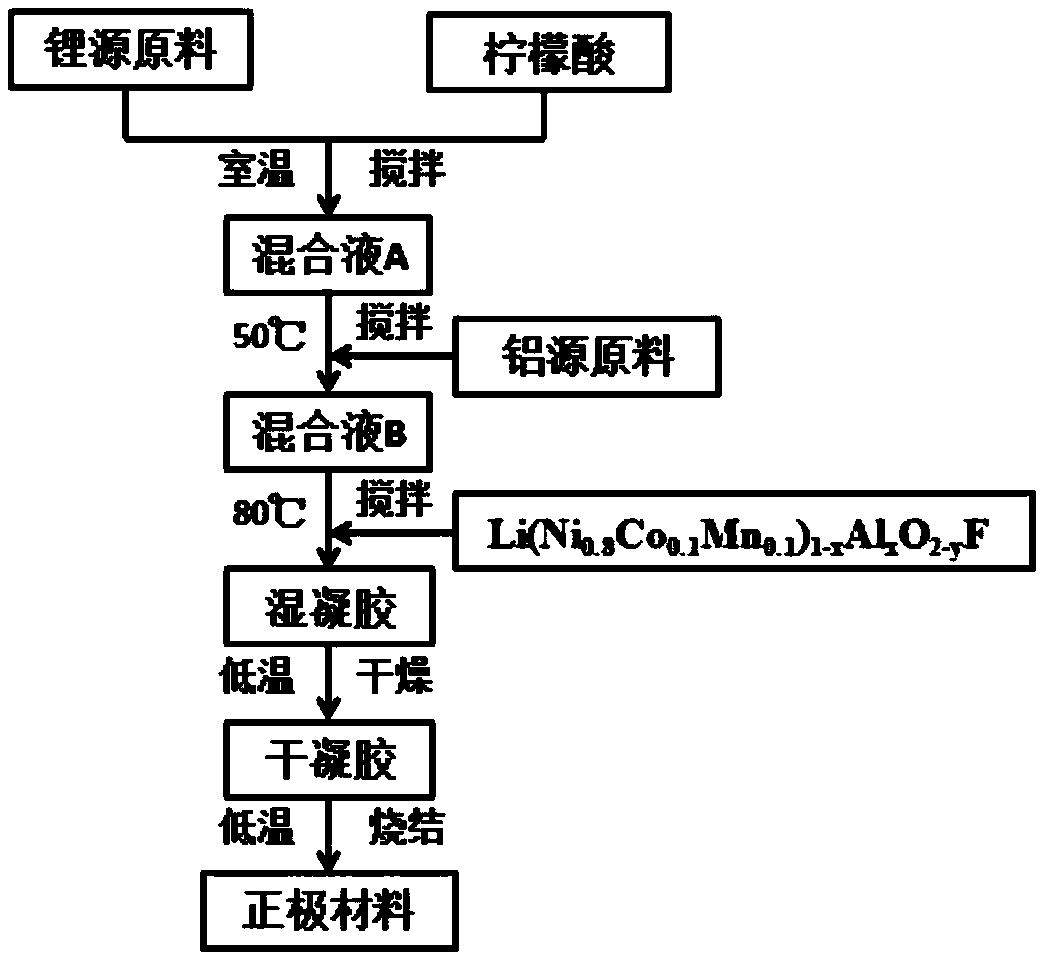

A kind of lithium battery material additive, lithium battery material and preparation method thereof

ActiveCN114464812BEvenly distributedGood material consistencyCell electrodesNon-aqueous electrolyte cellsPhysical chemistryCitric acid

The invention discloses a lithium battery material additive, a lithium battery material and a preparation method thereof, belonging to the technical field of lithium batteries. The preparation method of the lithium battery material additive includes the following steps: mixing a citric acid solution with an acetate solution containing a coating element, and then adjusting the pH to 6-10 with a pH adjuster; the coating element includes Sr, Zr, B, Al and At least two of Ti; the volume ratio of the citric acid solution and the acetate solution is 1.5-2:1, the concentration of the citric acid solution is 0.08-0.12mol / L, and the concentration of the coating element in the acetate solution is 0.008 ‑0.012mol / L. By using the sol-gel method to prepare lithium battery material additives containing various coating elements, various coating elements can be uniformly mixed and have better material consistency. The surface is uniformly coated, and the surface residual alkali content of the high-nickel ternary material can also be effectively reduced.

Owner:宜宾锂宝新材料有限公司

Lithium ion battery positive electrode material as well as preparation method and application thereof

ActiveCN113782743AReduce contentImprove stabilitySecondary cellsPositive electrodesLithium electrodeElectrode material

The invention discloses a lithium ion battery positive electrode material as well as a preparation method and application thereof. The preparation method comprises the steps of dissolving a water-soluble titanium source and a water-soluble aluminum source in water according to a chemical general formula Al2Ti<1+a>O5, and uniformly mixing to obtain a mixed solution; uniformly mixing hydrogel and a ternary positive electrode material to obtain a first mixture; dropwise adding the mixed solution into the first mixture to obtain a second mixture; and performing plasma activation on the second mixture, sintering, crushing and sieving to obtain the lithium ion battery positive electrode material. The preparation method is simple to operate and low in cost, and the obtained lithium ion battery positive electrode material is low in residual alkali content, stable in interface structure and excellent in electrochemical performance.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

Method for modifying phosphorus-containing compound on surface of high-nickel ternary material and lithium ion battery

InactiveCN113540435AAvoid centralized stability issuesImprove surface propertiesCell electrodesSecondary cellsElectrical batteryMixed materials

The invention provides a method for modifying a phosphorus-containing compound on the surface of a high-nickel ternary material, which comprises the following steps of mechanically mixing the high-nickel ternary material and a modifier to obtain a mixed material, and carrying out heat treatment on the mixed material in an oxygen atmosphere. According to the method, surface modification of the high-nickel ternary material is completed on the premise that wet mixing is not adopted; and the surface modification of the high-nickel material and the improvement of the electrochemical performance are realized by selecting a proper modification material and a proper heat treatment temperature. The selected preparation method is simple and controllable, and existing equipment can be used for preparation.

Owner:NINGBO RONBAY LITHIUM BATTERY MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com