Lithium ion battery cathode material and preparation method thereof

A technology for lithium ion batteries and positive electrode materials, which is applied to the field of positive electrode materials for lithium ion batteries and its preparation, can solve the problems of low nickel content in a ternary system, and cannot achieve surface cleaning to remove residual alkali, etc., so as to improve surface structure and improve interface stability. The effect of reducing the residual alkali content on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

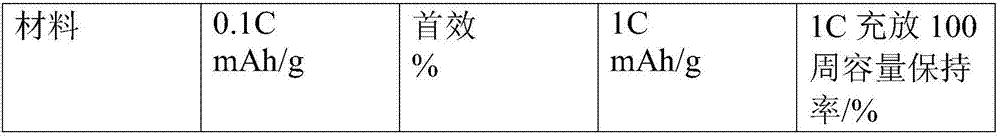

Examples

Embodiment 1

[0023] Precursor Ni 0.8 co 0.1 mn 0.1 (OH) 2 , according to lithium hydroxide monohydrate (Li / (Ni+Co+Mn) molar ratio 1.05), additive nano-Al 2 o 3 (Al / (Ni+Co+Mn) molar ratio 0.06) After the three materials were uniformly mixed in a high-speed mixer, they were sintered at 790° C. for 12 hours in a pure oxygen atmosphere to obtain an unmodified powder. The unmodified powder and water are mixed at a ratio of 1000g / 1L, stirred, centrifuged, dried and pulverized at 100°C to obtain a water-washed powder. The water-washed powder and boron oxide (addition amount: B / (Ni+Co+Mn) molar ratio 0.01) were mixed by dry method, and then sintered at 800°C for 5 hours under pure oxygen atmosphere to obtain a high-nickel cathode material.

Embodiment 2

[0025] Precursor Ni 0.82 co 0.12 mn 0.6 (OH) 2 , according to lithium hydroxide monohydrate (Li / (Ni+Co+Mn) molar ratio 1.04), additive nano ZrO 2 (Zr / (Ni+Co+Mn) molar ratio 0.01) After the three materials are uniformly mixed in a high-speed mixer, they are sintered at 770° C. for 20 h in a pure oxygen atmosphere to obtain an unmodified powder. The unmodified powder is mixed with water at a ratio of 700g / 1L, stirred, centrifuged, dried and pulverized at 100°C to obtain a water-washed powder. After dry mixing the water-washed powder and boric acid (addition amount: B / (Ni+Co+Mn) molar ratio 0.02), sintering at 700°C for 2 hours under a pure oxygen atmosphere to obtain a high-nickel cathode material.

Embodiment 3

[0027] Precursor Ni 0.85 co 0.1 mn 0.5 (OH) 2 According to Lithium Hydroxide Monohydrate (Li / (Ni+Co+Mn) molar ratio 1.05), additive nano-MgO (Mg / (Ni+Co+Mn) molar ratio 0.03) three materials are mixed evenly in a high-speed mixer Finally, under pure oxygen atmosphere, sinter at 730°C for 15h to obtain unmodified powder. The unmodified powder is mixed with water at a ratio of 500g / 1L, stirred, centrifuged, dried and pulverized at 100°C to obtain a water-washed powder. The water-washed powder and boron oxide (addition amount: B / (Ni+Co+Mn) molar ratio 0.03) were mixed by dry method, and then sintered at 650°C for 3 hours under pure oxygen atmosphere to obtain a high-nickel cathode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com