A kind of lithium battery material additive, lithium battery material and preparation method thereof

A technology of additives and lithium batteries, applied in battery electrodes, lithium batteries, non-aqueous electrolyte batteries, etc., can solve the problems of low additive content, poor material consistency, uneven additive mixing, etc., achieve the best material consistency and reduce residual alkali content , Improve the effect of electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

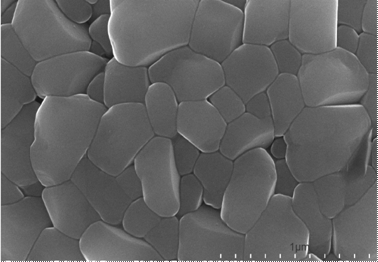

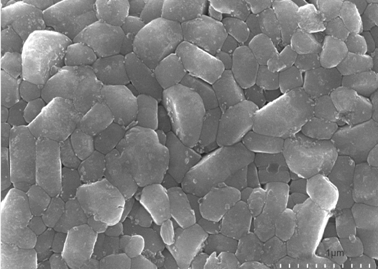

Image

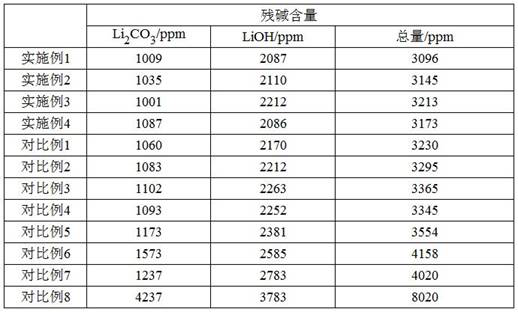

Examples

preparation example Construction

[0035] The present application proposes a method for preparing a lithium battery material additive, which includes the following steps: mixing a citric acid solution with an acetate solution containing a coating element, and then adjusting the pH to 6-10 with a pH adjuster.

[0036] Wherein, the coating elements include at least two of Sr, Zr, B, Al and Ti. That is, the coating element may contain any two of Sr, Zr, B, Al and Ti at the same time, and may also contain any three, four or five of Sr, Zr, B, Al and Ti at the same time.

[0037] The volume ratio of citric acid solution to acetate solution can be 1.5-2:1, such as 1.5:1, 1.6:1, 1.7:1, 1.8:1, 1.9:1 or 2:1, etc., or 1.5- Any other value in the 2:1 range.

[0038] If the citric acid solution is too small, the coating elements (except B) in the acetate solution cannot be effectively and uniformly complexed.

[0039] The concentration of citric acid solution can be 0.08-0.12mol / L, such as 0.08mol / L, 0.09mol / L, 0.1mol / L,...

Embodiment 1

[0078] The present embodiment provides a lithium battery material, and its preparation method is as follows:

[0079] The acetate solution containing the coating element was added dropwise to the citric acid solution at a rate of 1 mL / min, and then adjusted to 8 with a pH adjuster; then, the high nickel ternary material was added to the lithium battery material additive and continued stirring and mixing , followed by drying and sintering.

[0080] Among them, the cladding elements are composed of Sr, Zr, B, Al and Ti.

[0081] The volume ratio of the citric acid solution and the acetate solution is 2:1, the concentration of the citric acid solution is 0.1 mol / L, and the total concentration of the coating elements in the acetate solution is 0.01 mol / L. Specifically, the concentration of Sr in the acetate solution is 0.001mol / L, the concentration of Zr in the acetate solution is 0.001mol / L, the concentration of B in the acetate solution is 0.005mol / L, and the concentration of A...

Embodiment 2

[0086] The present embodiment provides a lithium battery material, and its preparation method is as follows:

[0087] The acetate solution containing the coating element was added dropwise to the citric acid solution at a rate of 0.5 mL / min, and then adjusted to 6 with a pH adjuster; then, the high-nickel ternary material was added to the lithium battery material additive and continued to stir Mixing, then drying, and sintering.

[0088] Among them, the cladding elements consist of Zr, Al and Ti.

[0089] The volume ratio of the citric acid solution and the acetate solution is 1.5:1, the concentration of the citric acid solution is 0.08mol / L, and the total concentration of the coating elements in the acetate solution is 0.008mol / L. The specific concentration of Zr in the acetate solution is 0.002mol / L, the concentration of Al in the acetate solution is 0.002mol / L, and the concentration of Ti in the acetate solution is 0.004mol / L.

[0090] The citric acid solution is obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com