High-nickel ternary material, surface modification method and lithium ion battery

A high-nickel ternary material, lithium-ion battery technology, applied in battery electrodes, secondary batteries, secondary battery repair/maintenance, etc. The effect of suppressing excessive precipitation of Li+ and protecting the structure stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

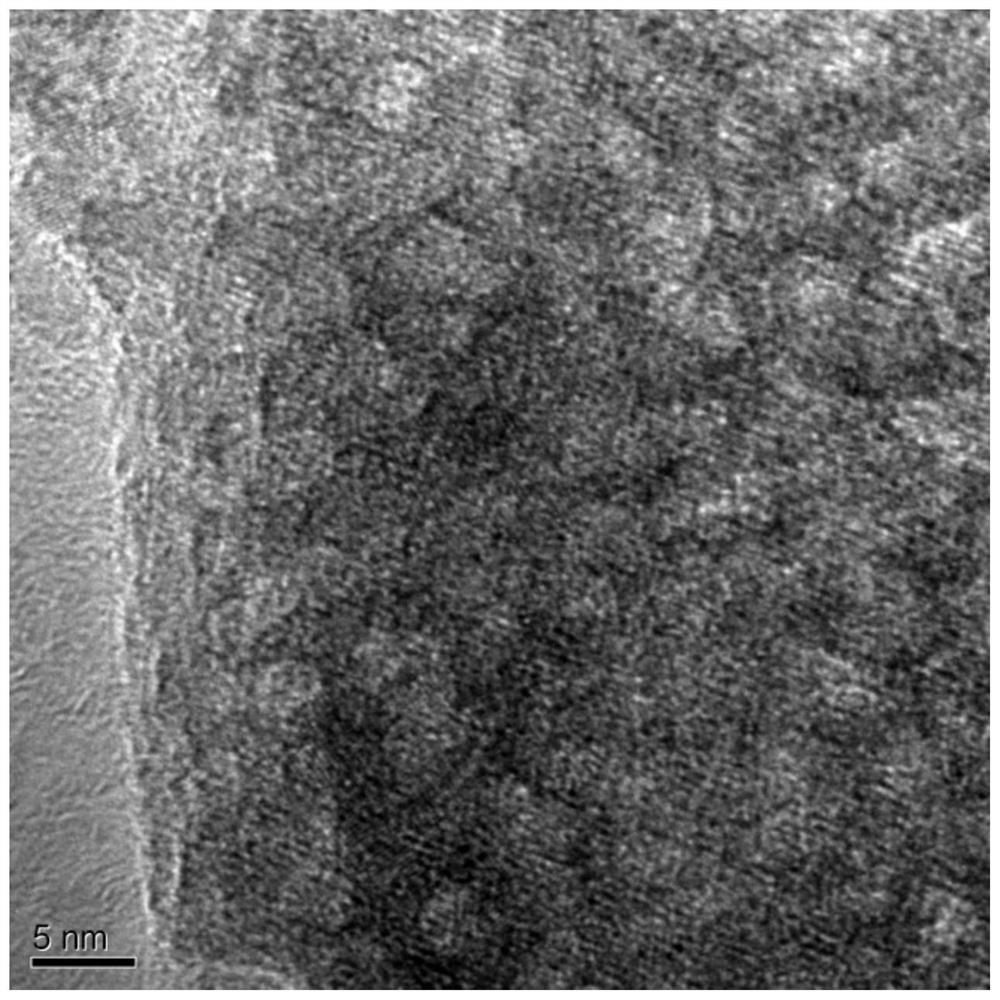

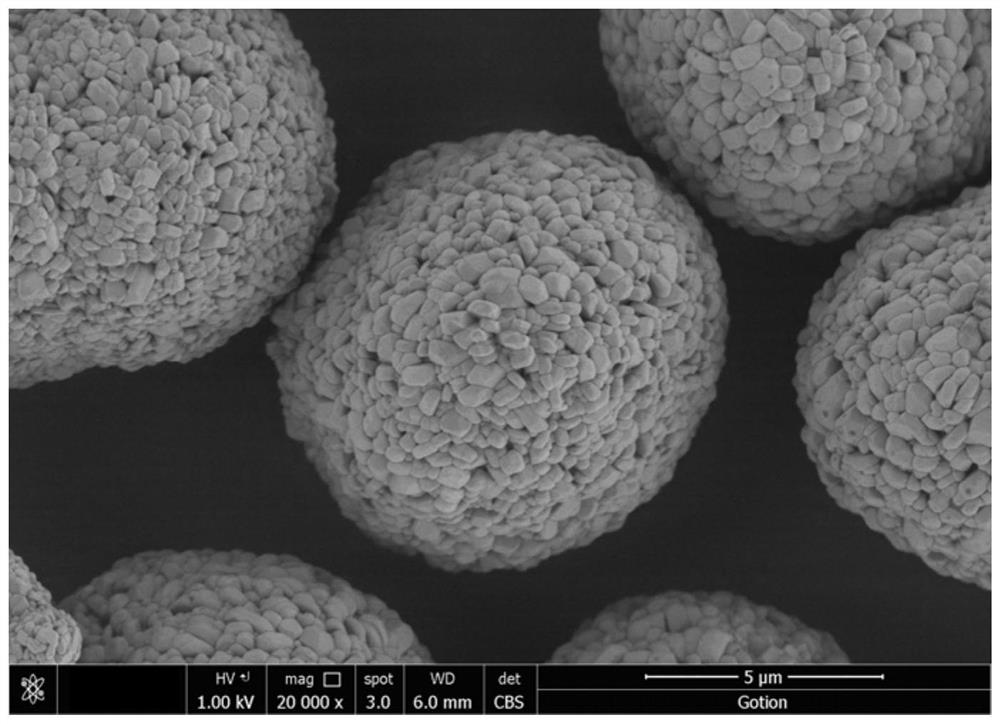

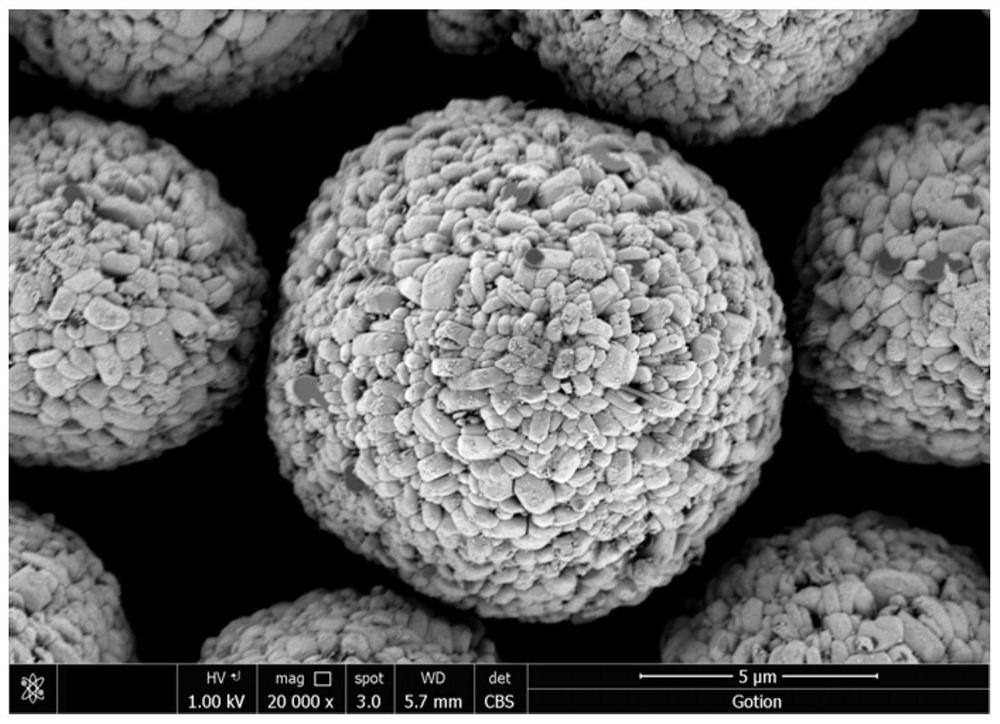

Image

Examples

Embodiment 1

[0051] Pour 50kg of deionized water into a water washing kettle lined with polytetrafluoroethylene, then add the first additive composed of lithium sulfate solution to the deionized water, stir evenly, and then burn the powder according to the high-nickel ternary material and The solid-to-liquid ratio of deionized water is 1:1 and LiNi is added 0.85 co 0.10 mn 0.05 o 2 Burn the powder and stir at a high speed to form a uniform first slurry, wherein, in the first additive, Li + The effective ion content is 0.05wt%, and the addition amount of the first additive is 5wt% of the mass of the added high-nickel ternary material-sintered powder.

[0052] By TiO 2+ :Al 3+ :AlO 2 - The molar ratio of =1:1:5 is added dropwise to the first slurry simultaneously and the content is that the effective ion content is 0.01wt% TiOSO 4 Sulfuric acid solution, 0.01wt% Al 2 (SO 4 ) 3 Sulfuric acid solution and 0.05wt% NaAlO 2 Sodium hydroxide solution, TiOSO 4 The amount of sulfuric ac...

Embodiment 2

[0062] In embodiment 1, the high-nickel ternary material-sintered powder material is replaced by LiNi 0.90 co 0.05mn 0.05 o 2 Burn powder material, successively wash with water, centrifugal and coulter vacuum drying steps are with embodiment 1. Then, the dried powder was placed in a muffle furnace in an oxygen atmosphere, and the temperature was raised to 650° C. for 5 hours. Finally, naturally cool to room temperature to obtain low residual alkali and uniform surface coating of Al 2 o 3 and TiO 2 LiNi 0.90 co 0.05 mn 0.05 o 2 .

Embodiment 3

[0064] In embodiment 1, the high-nickel ternary material-sintered powder material is replaced by LiNi 0.65 co 0.20 mn 0.15 o 2 Burn powder material, washing successively, centrifugal drying and plow blade vacuum drying steps are the same as embodiment 1. Then, the dried high-nickel ternary material was placed in a muffle furnace in an air atmosphere, and the temperature was raised to 700° C. for 5 hours. Finally, naturally cool to room temperature to obtain low residual alkali and uniform surface coating of Al 2 o 3 and TiO 2 LiNi 0.65 co 0.20 mn 0.15 o 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com