Positive electrode material and preparation method and application thereof

A technology of positive electrode materials and positive electrode active materials, which is applied in the field of positive electrode materials and its preparation, can solve the problems of lithium ion transmission path blockage, excessive capacity decay, low thermal stability and safety, etc., and achieve improved capacity and cycle safety performance , Improve the rate performance and cycle performance, the effect of excellent rate performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] According to another aspect of the present invention, the present invention also relates to the preparation method of the positive electrode material, comprising the following steps:

[0060] The mixture of the lithium source, the ternary precursor, the indium source and the antimony source is subjected to the first heat treatment to obtain the positive electrode active material; the positive electrode active material is washed with a washing liquid containing soluble cobalt salt, and the washed mixed system is subjected to Aging and drying to obtain a positive electrode substrate to which cobalt hydroxide is attached;

[0061] performing a second heat treatment on the mixture of the cobalt hydroxide-attached positive electrode substrate and the strontium source to obtain a strontium-coated positive electrode composite material; and performing a third heat treatment on the mixture of the strontium-coated positive electrode composite material and the boron source.

[006...

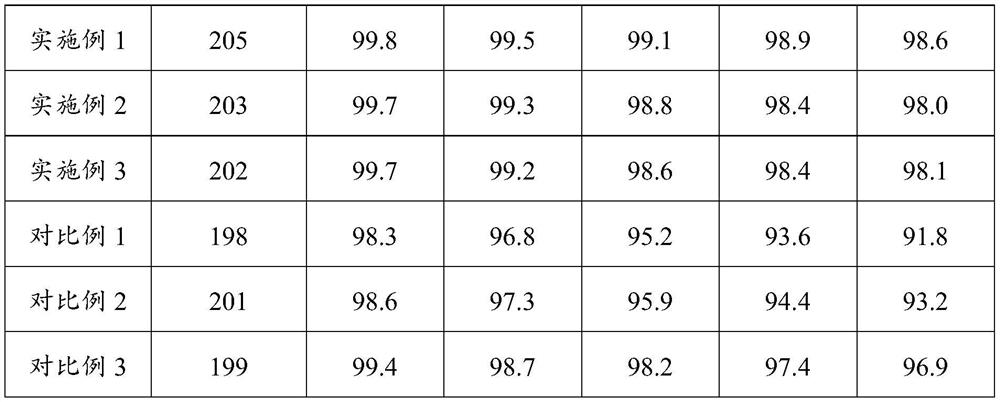

Embodiment 1

[0091] A method for preparing a positive electrode material, comprising the steps of:

[0092] (a) Add the lithium source, the ternary precursor, the indium source and the antimony source into a high-speed mixer in a certain molar ratio and mix them uniformly to obtain a mixed powder. The mixed powder is subjected to the second step in an oxygen atmosphere. 1. High temperature sintering, the flow rate of oxygen atmosphere is 1.2m 3 / h, the temperature of the first high-temperature sintering is 730°C, and the time is 10h; after the sintering is completed, the positive active material LiNi can be obtained after cooling 0.9 co 0.05 mn 0.02 In 0.01 Sb 0.02 o 2 ;

[0093] Among them, the lithium source is lithium hydroxide; the ternary precursor is NCM811; the indium source is indium hydroxide; the antimony source is antimony hydroxide; the molar ratio of lithium source, ternary precursor, indium source and antimony source is 1.1:1: 0.01:0.02;

[0094] (b) LiNi in step (a) ...

Embodiment 2

[0101] A method for preparing a positive electrode material, comprising the steps of:

[0102] (a) Add the lithium source, the high-nickel ternary precursor, the indium source and the antimony source together in a certain molar ratio into a high-speed mixer and mix them uniformly to obtain a mixed powder, which is then placed in an oxygen atmosphere Carry out the first high temperature sintering, the flow rate of oxygen atmosphere is 2m 3 / h, the temperature of the first high-temperature sintering is 900°C, and the time is 6h; after the sintering is completed, the positive electrode active material LiNi is obtained after cooling 0.9 co 0.05 mn 0.02 In 0.01 Sb 0.02 o 2 ;

[0103] Among them, the lithium source is lithium hydroxide; the ternary precursor is NCM811; the indium source is indium hydroxide; the antimony source is antimony hydroxide; the molar ratio of lithium source, ternary precursor, indium source and antimony source is 1.1:1: 0.01:0.02;

[0104] (b) LiNi ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com