Method for improving residual alkalinity on surface of ternary positive electrode material of lithium ion battery

A technology for lithium-ion batteries and cathode materials, which is applied in battery electrodes, electrical components, secondary batteries, etc., can solve problems such as capacity reduction, and achieve the effects of reducing residual alkali content, simple process flow, and improving interface performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

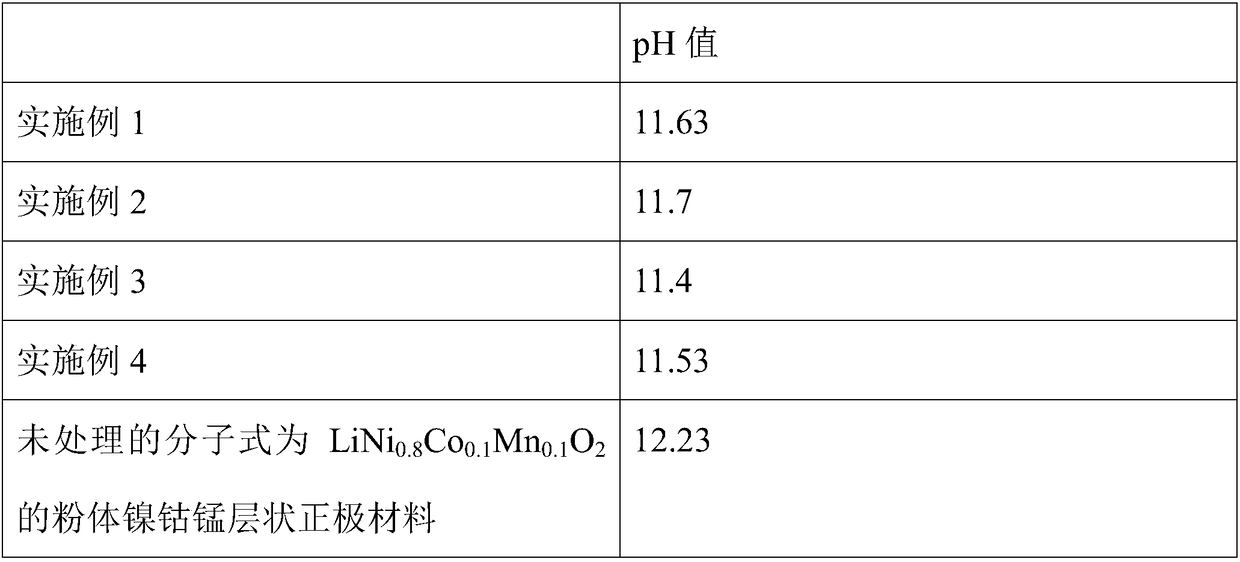

Examples

Embodiment 1

[0020] A method for improving the residual alkalinity on the surface of a lithium-ion battery ternary positive electrode material, comprising the following steps:

[0021] S1, the molecular formula of 80g is LiNi 0.8 co 0.1 mn 0.1 o 2 The powdered nickel-cobalt-manganese layered positive electrode material is mixed with 400 g of water at a temperature of 80 ° C, and centrifuged to obtain the washed powder material;

[0022] S2. Add 0.0004g of lithium nitrate to 16g of absolute ethanol and mix evenly, then add water to wash the powder material, mix evenly, heat and evaporate completely, dry at 80°C, and sinter at 800°C for 1h to obtain a lithium-ion battery ternary positive electrode material, sinter The atmosphere is pure oxygen.

Embodiment 2

[0024] A method for improving the residual alkalinity on the surface of a lithium-ion battery ternary positive electrode material, comprising the following steps:

[0025] S1, the molecular formula of 40g is LiNi 0.7 co 0.15 mn 0.15 o 2 The powdered nickel-cobalt-manganese layered positive electrode material is mixed with 40 g of water at a temperature of 60 ° C, and centrifuged to obtain the washed powder material;

[0026] S2. Add 0.0004g of lithium nitrate to 40g of absolute ethanol and mix evenly, then add water to wash the powder material, mix evenly, rotate evaporate completely, dry at 120°C, and sinter at 100°C for 3h to obtain a lithium-ion battery ternary positive electrode material, and sinter The atmosphere is pure oxygen.

Embodiment 3

[0028] A method for improving the residual alkalinity on the surface of a lithium-ion battery ternary positive electrode material, comprising the following steps:

[0029] S1, the molecular formula of 50g is LiNi 0.9 co 0.05 mn 0.05 o 2 The powdered nickel-cobalt-manganese layered positive electrode material is mixed with 100 g of water at a temperature of 10 ° C, and centrifuged to obtain the washed powder material;

[0030] S2. Add 0.001g of lithium nitrate to 50g of absolute ethanol and mix evenly, then add water to wash the powder material, mix evenly, rotary evaporate completely, dry at 60°C, sinter at 700°C, and sinter for 2 hours to obtain a lithium-ion battery ternary Cathode material, the sintering atmosphere is pure oxygen.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com