A kind of double modified high nickel ternary material and preparation method thereof

A high-nickel ternary material, high-nickel technology, applied in electrical components, active material electrodes, positive electrodes, etc., can solve the reduction of discharge specific capacity, but not fundamentally solve the residual alkali content and cycle performance of high-nickel ternary materials. Deterioration and other problems to achieve the effect of slowing down side reactions, reducing surface residual alkali content, and reducing surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

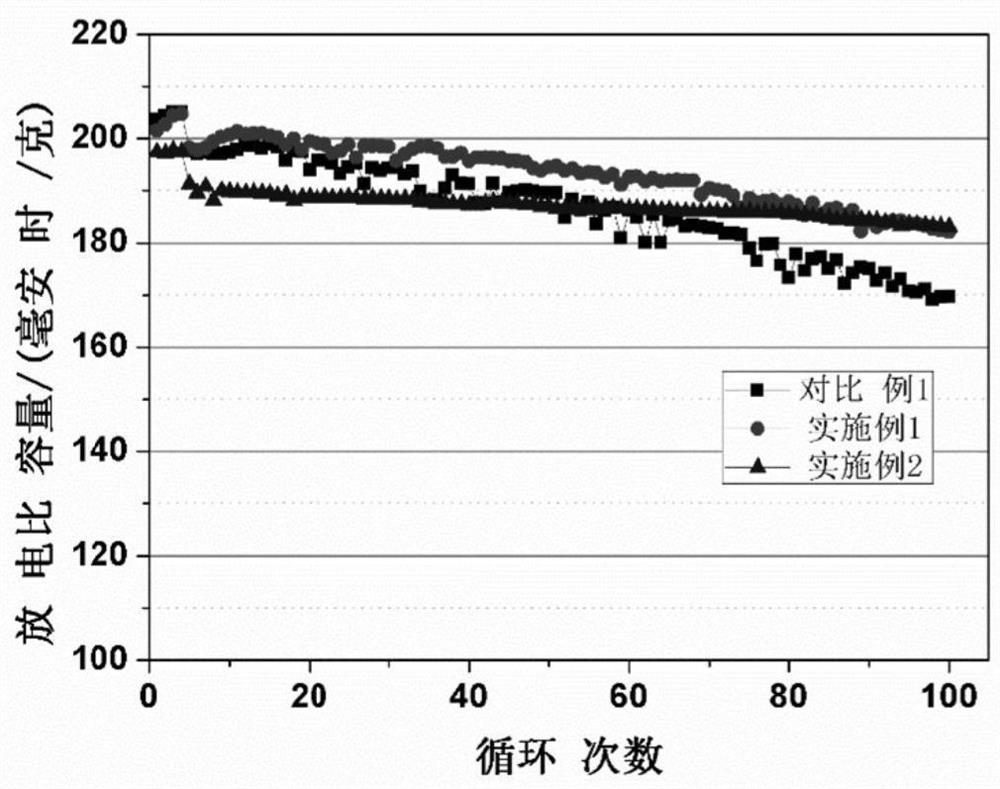

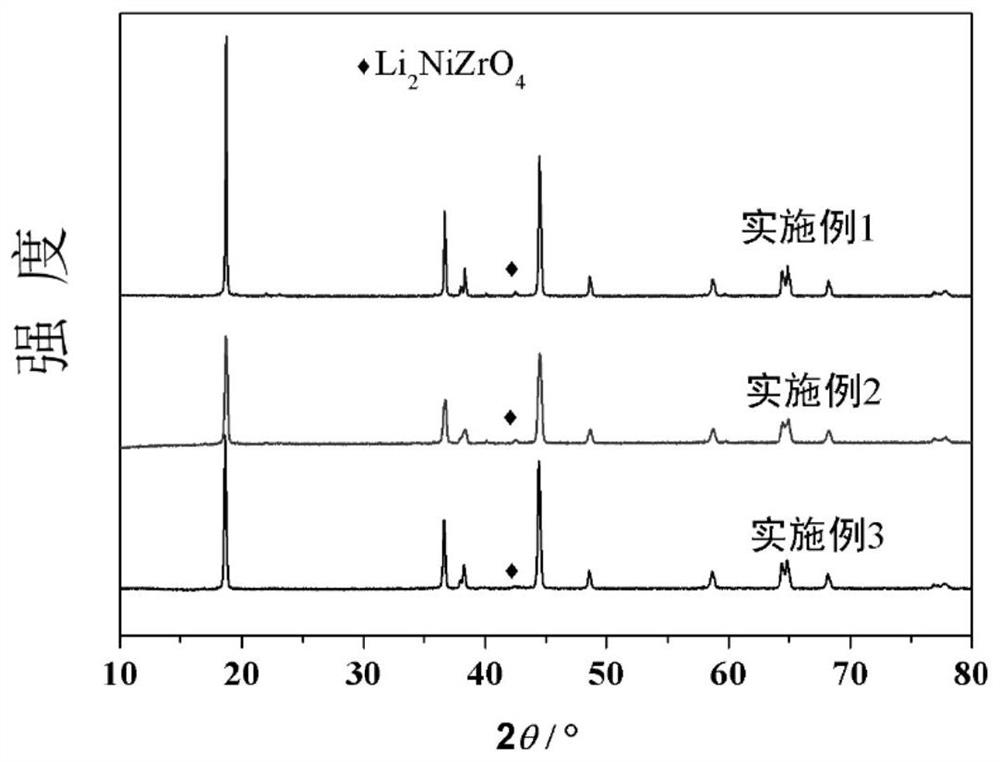

[0049] (1) Weigh 100.00g of Ni according to the molar ratio of n(Li):n(Ni+Co+Mn+Zr)=1.02 0.8 Co 0.1 Mn 0.1 (OH) 2 Precursor and 46.87 g of LiOH·H 2 The mixture was ball-milled and mixed for 3 hours to obtain a mixture. The mixture was put into an alumina crucible, placed in an atmosphere furnace, and calcined at 750° C. for 20 hours under an oxygen atmosphere. After the material was cooled, the material was crushed and passed through a 325-mesh sieve to obtain High nickel ternary base material LiNi 0.8 Co 0.1 Mn 0.1 O 2 (NCM811);

[0050] (2) Weigh 99.00g of the NCM811 base material of step (1) and 1.00g of nano-ZrO 2 , mixed with a high-efficiency mixer for 10 min to obtain ZrO 2 Coated high nickel ternary material;

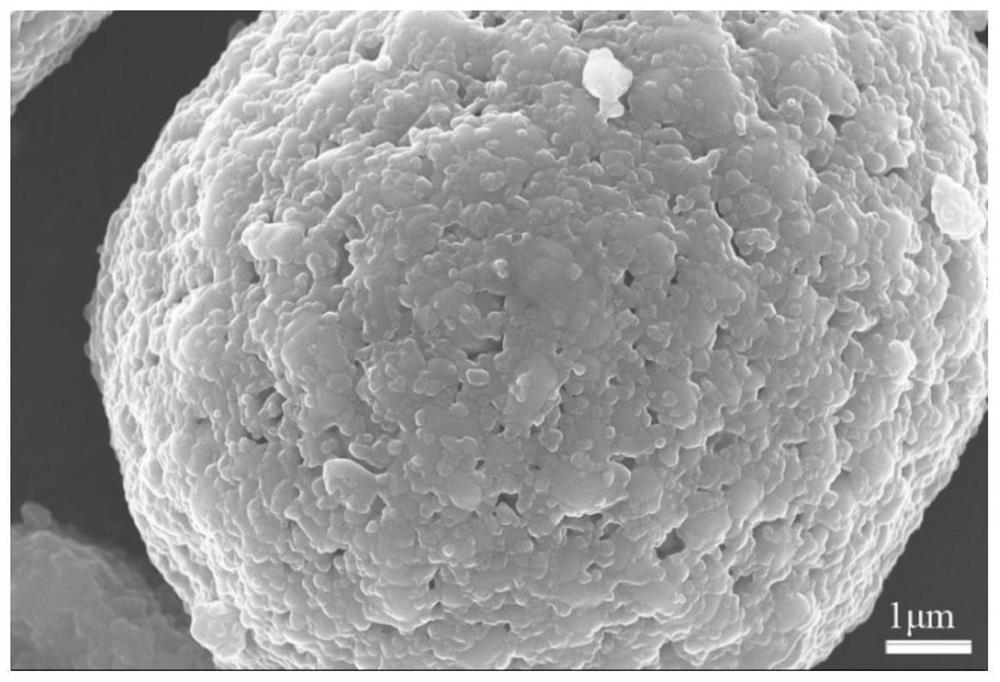

[0051] (3) the ZrO obtained in step (2) 2 The coated high-nickel ternary material was calcined at 750 °C for 3 hours in an oxygen atmosphere. After the material was cooled, the material was crushed and passed through a 325-mesh sieve to obtain Li 2 N...

Embodiment 2

[0053] (1) Weigh 100.00g of Ni according to the molar ratio of n(Li):n(Ni+Co+Mn+Zr)=1.05 0.8 Co 0.1 Mn 0.1 (OH) 2 Precursor and 48.72 g of LiOH H 2 The mixture was ball-milled and mixed for 3.5h to obtain a mixture. The mixture was put into an alumina crucible, put into an atmosphere furnace, and calcined at 780°C for 6h under an oxygen atmosphere. After the material was cooled, the material was crushed and passed through a 325 mesh sieve. Obtained high nickel ternary base material LiNi 0.8 Co 0.1 Mn 0.1 O 2 (NCM811);

[0054] (2) Weigh 97.00g of the NCM811 base material of step (1) and 3.00g of nano-ZrO 2 , mixed with a high-efficiency mixer for 40min to obtain ZrO 2 Coated high nickel ternary material;

[0055] (3) the ZrO obtained in step (2) 2 The coated high-nickel ternary material was calcined at 750°C for 10 hours in an oxygen atmosphere. After the material was cooled, the material was crushed and passed through a 325-mesh sieve to obtain Li 2 NiZrO 4 Doubl...

Embodiment 3

[0057] (1) Weigh 100.00g of Ni according to the molar ratio of n(Li):n(Ni+Co+Mn+Zr)=1.06 0.9 Co 0.05 Mn 0.05 (OH) 2 Precursor and 49.45 g of LiOH H 2 The mixture was ball-milled and mixed for 3 hours to obtain a mixture. The mixture was put into an alumina crucible, placed in an atmosphere furnace, and calcined at 700° C. for 15 hours under an oxygen atmosphere. After the material was cooled, the material was crushed and passed through a 325 mesh sieve to obtain High nickel ternary base material LiNi 0.9 Co 0.05 Mn 0.05 O 2 (NCM955);

[0058] (2) Weigh 97.00g of NCM955 base material of step (1) and 5.00g of nano ZrO 2 , mixed with a high-efficiency mixer for 60 min to obtain ZrO 2 Coated high nickel ternary material;

[0059] (3) the ZrO obtained in step (2) 2 The coated high-nickel ternary material was calcined at 650 °C for 8 hours in an oxygen atmosphere. After the material was cooled, the material was crushed and passed through a 325-mesh sieve to obtain Li 2 N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com