Rare earth permanent magnetic material and preparation method thereof

A technology of rare earth permanent magnets and magnetic powders, which is applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of magnet performance deterioration, achieve excellent comprehensive magnetic properties, enhance demagnetization coupling, and increase the effect of volume fraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

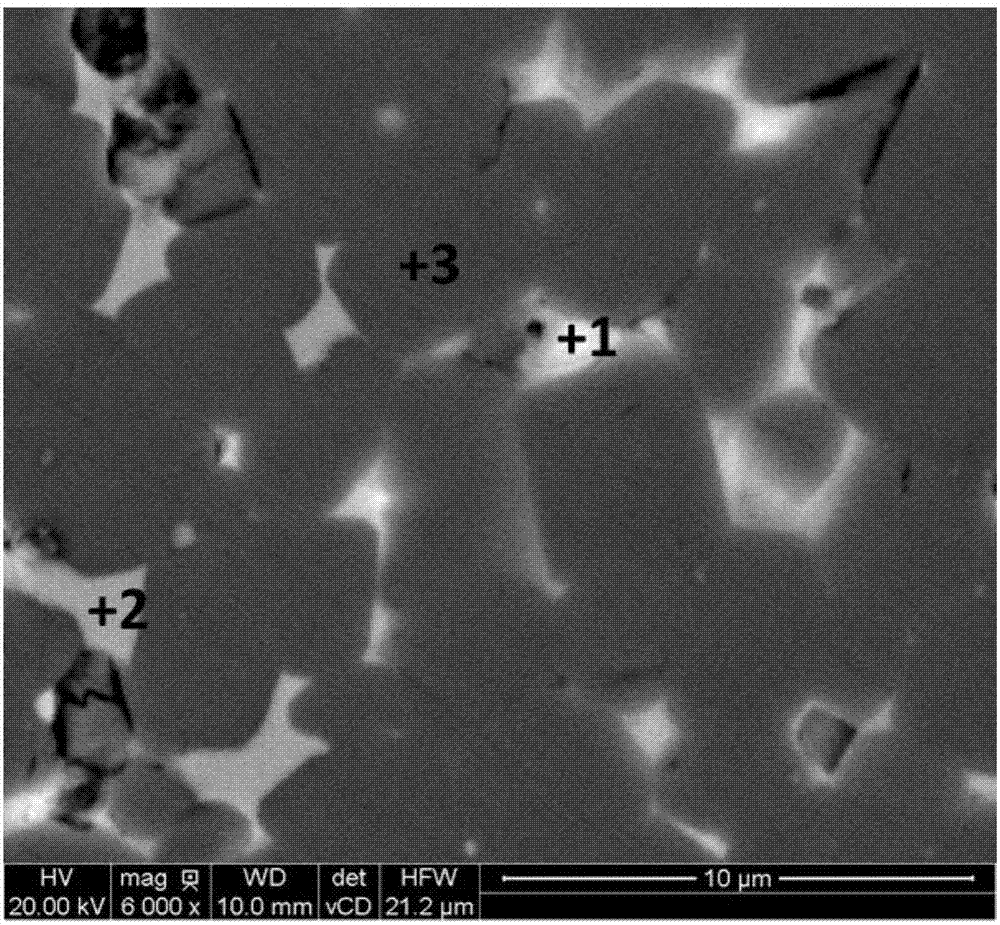

Image

Examples

preparation example Construction

[0030] The present invention provides a kind of preparation method of rare earth permanent magnet material, and it comprises the following several steps:

[0031] S1, providing main alloy magnetic powder and auxiliary alloy powder respectively, wherein the chemical formula of the main alloy magnetic powder is [(Pr r Nd 1-r ) x MM 1-x )] a T m b B c Fe 1-a-b-c , r, x, a, b, c are the mass percentages of the corresponding elements, and 0≤r≤1, 0≤x≤1, 28≤a≤33, 0≤b≤5, 0.85≤c≤1.5, MM is at least one of the high-abundance rare earths La and Ce, Tm is one or more of Fe, Ga, Co, Cu, Nb, Al, Zr elements, and the chemical formula of the auxiliary alloy powder is Ce y (Fe d m 1-d ) 1-y , y, d are the mass percentages of the corresponding elements, and 0.5≤y≤1, 0≤d≤1, where M is one or more of Cu, Al, Ga, Co, Ni;

[0032] S2, uniformly mixing the main alloy magnetic powder and the auxiliary alloy powder to obtain a mixed magnetic powder, wherein the mass percentage of the auxili...

Embodiment (1

[0056] According to [(Pr 0.2 Nd 0.8 ) 0.72 Ce 0.28 ] 30.5 al 0.2 Cu 0.1 Ga 0.1 Fe 68.1 B 1 Proportioning Proportioning of main alloy raw materials. The proportioned main alloy is put into the quick-setting furnace for melting after grinding, and the melting temperature is controlled at 1350°C, and the speed of the copper roller is kept at 1.2m / s during the melting. The main alloy quick-setting sheet with an average thickness of 0.3 mm to 0.5 mm is obtained through the quick-setting process. The obtained main alloy quick-setting sheet is placed in a hydrogen breaking furnace, hydrogen-charged and crushed to obtain the main alloy coarsely crushed powder, and then the obtained main alloy coarsely crushed powder is continued to be crushed in a jet mill protected by nitrogen to obtain an average particle size of 2μm ~ 3μm main alloy jet mill powder.

[0057] According to Ce 92 Fe 8 Proportioning of auxiliary alloy raw materials. The proportioned auxiliary alloy is pol...

Embodiment (2

[0063] Embodiment (2) The process of preparing rare earth permanent magnet material is basically the same as that of embodiment (1), except that the main alloy jet mill powder with a mass fraction of 97% is mixed with an auxiliary alloy powder with a mass fraction of 3%. And the sintering temperature in the sintering process is 1000°C.

[0064] The magnetic properties of the prepared rare earth permanent magnet material were tested at room temperature, and the test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com