Methanation catalyst taking rutile type TiO2 as carrier and preparation method of methanation catalyst

A methanation catalyst, rutile-type technology, applied in the field of methanation catalyst and its preparation with rutile TiO2 as the carrier, can solve the problems of small specific surface area of titanium dioxide, complex catalyst preparation process, low specific surface area of composite carrier, etc., and achieve good promotion Application potential, low active ingredient content, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

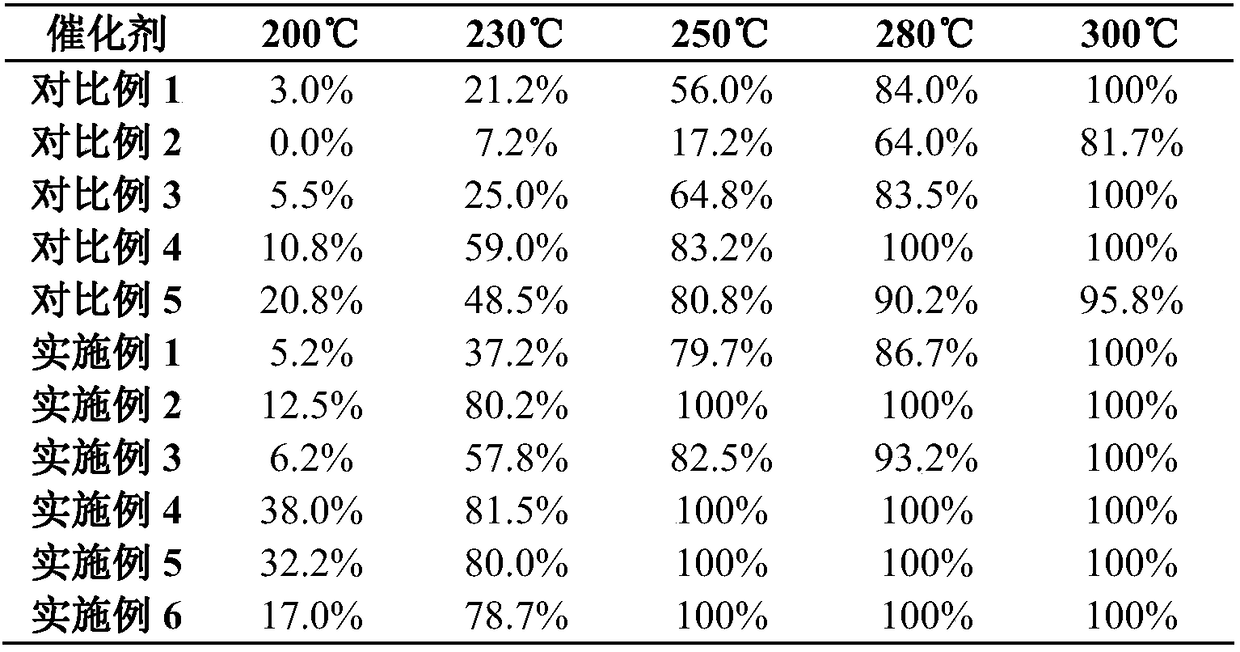

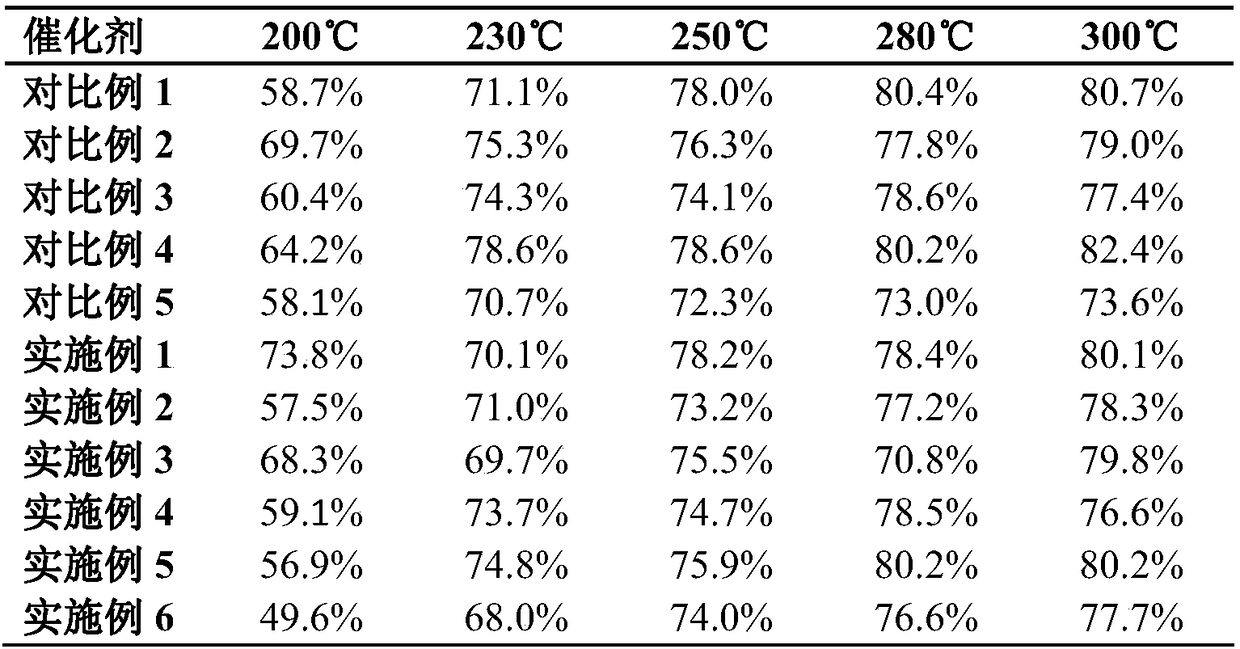

Examples

Embodiment 1

[0019] 1) Rutile TiO 2 Preparation of vector

[0020] Take 25g of pseudo-boehmite and put it into a kneader, add 200mL of deionized water, use dilute nitric acid at 50-80°C to adjust the pH value to 3-4, and knead to prepare aluminum sol. 500g rutile TiO 2 The powder is added to the prepared aluminum sol, mixed and kneaded into a plastic mass, and then extruded by an extruder. After the formed catalyst carrier is left at room temperature for 4-6 hours, it is dried at 80-120°C for 1-2 hours, and then calcined at 500°C for 4-8 hours;

[0021] 2) Impregnation of the carrier

[0022] Take 116.8g of nickel nitrate and 27.8g of cerium nitrate, add 200g of deionized water to dissolve, adjust the pH value with ammonia water and citric acid, and form a complex solution. Equal volume impregnated rutile TiO 2 carrier. Stand at room temperature for 4-6 hours, then dry at 110°C for 2-4 hours. The dried catalyst was calcined at 550° C. for 4 h in a muffle furnace.

Embodiment 2

[0024] 1) Rutile TiO 2 Preparation of vector

[0025] TiO 2 The preparation of carrier is the same as embodiment 1

[0026] 2) Impregnation of the carrier

[0027] Take 116.8g of nickel nitrate and 26.6g of lanthanum nitrate, add 200g of deionized water to dissolve, adjust the pH value with ammonia water and citric acid, and form a complex solution. Equal volume impregnated rutile TiO 2 carrier. Stand at room temperature for 4-6 hours, then dry at 110°C for 2-4 hours. The dried catalyst was calcined at 550° C. for 4 h in a muffle furnace. .

Embodiment 3

[0029] 1) Rutile TiO 2 Preparation of vector

[0030] TiO 2 The preparation of carrier is the same as embodiment 1

[0031] 2) Impregnation of the carrier

[0032] Take 116.8g of nickel nitrate, 13.9g of cerium nitrate, and 13.3g of lanthanum nitrate, add 200g of deionized water to dissolve, adjust the pH value with ammonia water and citric acid, and form a complex solution. Equal volume impregnated rutile TiO 2carrier. Stand at room temperature for 4-6 hours, then dry at 110°C for 2-4 hours. The dried catalyst was calcined at 550° C. for 4 h in a muffle furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com