Catalyst for aromatization of low-carbon mixed hydrocarbons in Fischer-Tropsch synthesis tail gas and its preparation method and use

A technology of catalysts and mixed hydrocarbons, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve good selectivity, low carbon deposition, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

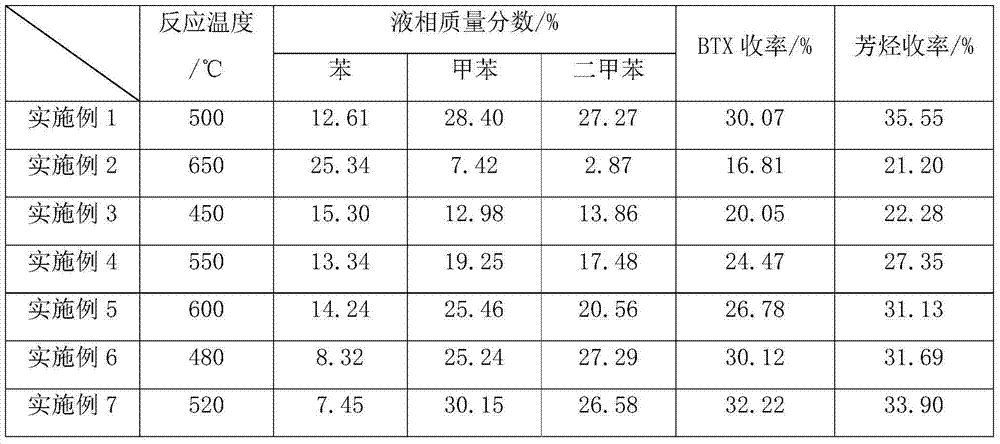

Embodiment 1

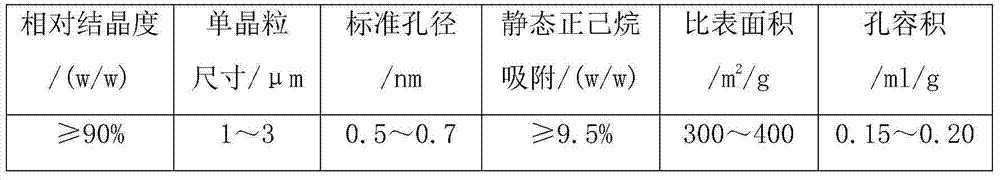

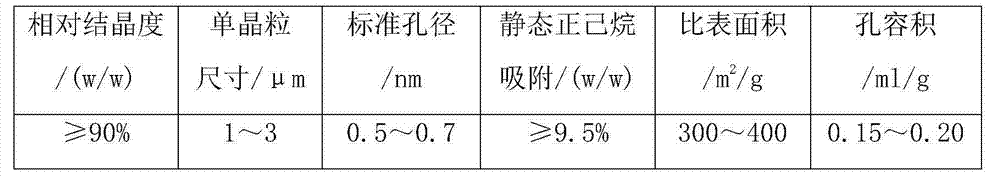

[0026] Prepare ZSM-5 molecular sieve according to the method described in patent CN102874843A: mix 8g aluminum isopropoxide, 20g tetraethyl orthosilicate, 25g tetrapropylammonium hydroxide (25%wt), and 120g water evenly, then stir and age After 12 hours, dry the aged sol-gel into dry glue, then grind the dry glue into powdery dry glue powder to obtain dry glue seed crystals; mix 30g of aluminum nitrate, 1200g of water glass (27.5wt%) and Prepare a mixed solution with 600g of water, stir evenly, then add all the above-mentioned dry glue seeds to the mixed solution, stir evenly, put the above-mentioned mixed solution with dry glue seeds into the reaction kettle, and statically crystallize at 120°C After 72 hours, the crystallized product was obtained; the crystallized product was taken out, washed with water, dried, and roasted at 600°C for 2 hours to obtain a nano-sized ZSM-5 molecular sieve with a relative crystallinity of 90.7%, a single crystal grain size of 1.5 μm, and stati...

Embodiment 2

[0030] Prepare ZSM-5 molecular sieve according to the method described in patent CN102874843A: 8g of aluminum isopropoxide, 22g of tetraethyl orthosilicate, 27g of tetrapropylammonium hydroxide (25%wt), and 125g of water are evenly mixed, then stirred and aged After 4 hours, dry the aged sol-gel into dry glue, then grind the dry glue into powdery dry glue powder to obtain dry glue seed crystals; mix 30g of aluminum nitrate, 1100g of water glass (27.5wt%) and Make a mixed solution with 570g of water, stir evenly, then add all the above-mentioned dry glue seeds to the mixed solution, stir evenly, put the above-mentioned mixed solution with dry glue seeds into the reaction kettle, and statically crystallize at 130°C After 60 hours, the crystallized product was obtained; the crystallized product was taken out, washed with water, dried, and roasted at 580°C for 4 hours to obtain a nano-sized ZSM-5 molecular sieve with a relative crystallinity of 92.3%, a single crystal grain size of...

Embodiment 3

[0034] Prepare ZSM-5 molecular sieve according to the method described in patent CN102874843A: mix 8g aluminum isopropoxide, 24g tetraethyl orthosilicate, 30g tetrapropylammonium hydroxide (25%wt), and 135g water evenly, then stir and age After 8h, dry the aged sol-gel into dry glue, then grind the dry glue into powdery dry glue powder to obtain dry glue seed; 28g aluminum nitrate, 1050g water glass (27.5wt%) and Make a mixed solution with 450g of water, stir evenly, then add all the above-mentioned dry glue seeds to the mixed solution, stir evenly, put the above-mentioned mixed solution with dry glue seeds into the reaction kettle, and statically crystallize at 150°C After 48 hours, the crystallized product was obtained; the crystallized product was taken out, washed with water, dried, and roasted at 570°C for 6 hours to obtain a nano-sized ZSM-5 molecular sieve with a relative crystallinity of 95.5% and a single crystal grain size of 1.2 μm. The adsorption is 12.2%, the pore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com