Nano composite material simultaneously modified by non-noble metal cocatalyst and defects as well as preparation method and application thereof

A nano-composite material and co-catalyst technology, applied in the preparation of carbon-based compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of optimization of preparation conditions and low separation efficiency of photogenerated electrons and holes, and achieve the preparation conditions Optimize and improve the efficiency and high yield of photocatalytic hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

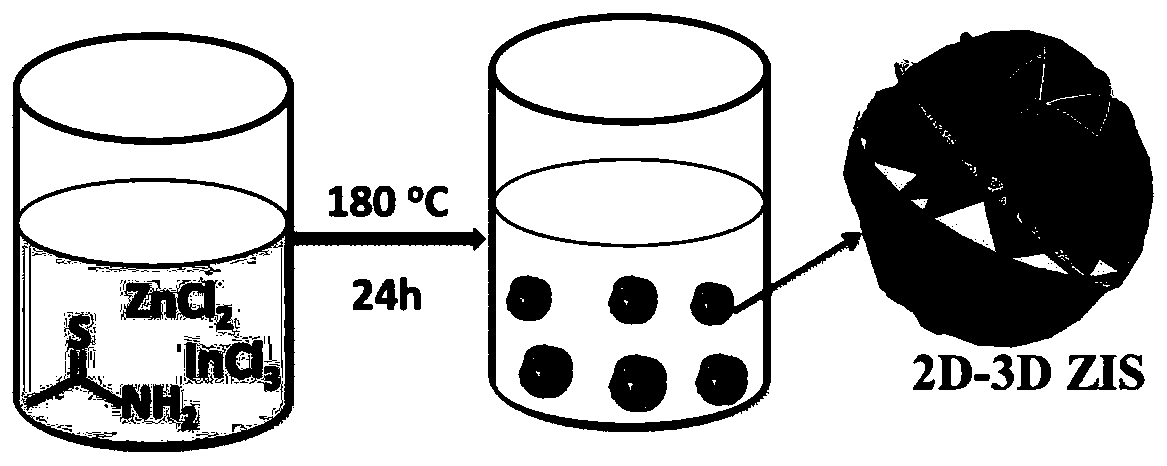

[0041] Such as figure 1 As shown, this embodiment prepares 2D-3D ZIS nanomaterials according to the following steps:

[0042] Step 1, weigh 0.8mmol ZnCl 2 , 1.6mmol InCl 3 4H 2 O and 3.5 mmol CH 3 CSNH 2 In a 100mL polytetrafluoroethylene reactor, add 60mL deionized water-ethanol mixture (30mL water and 30mL ethanol) as a solvent, stir and dissolve to form a uniformly mixed solution;

[0043] Step 2. Put the polytetrafluoroethylene reaction kettle into the steel-jacketed kettle and seal it and keep it at 180°C for 24 hours; after the reaction kettle is naturally cooled to room temperature, the obtained precipitate is alternately washed several times with deionized water and ethanol, and the final product Vacuum drying at 60°C yields 2D-3D ZIS.

Embodiment 2

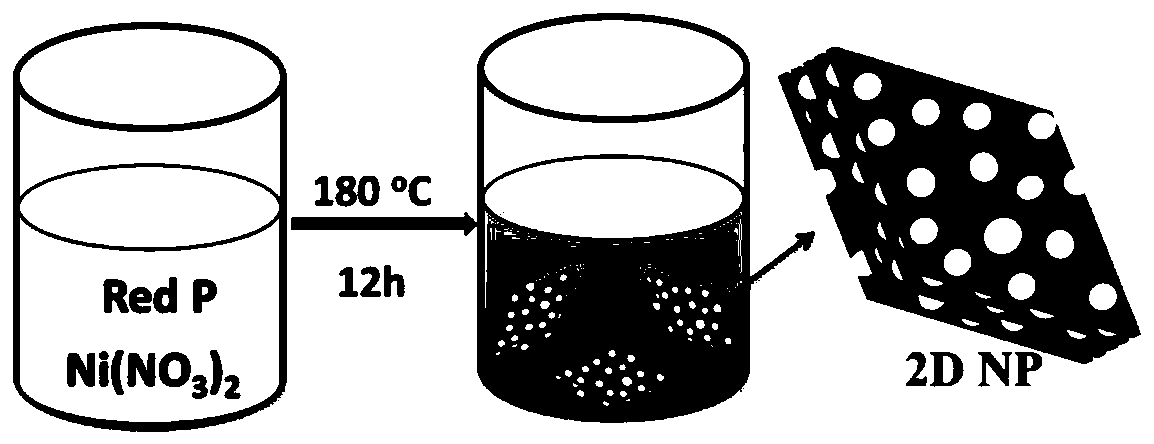

[0045] Such as figure 2 As shown, the present embodiment prepares 2D NP nanomaterials according to the following steps:

[0046] Step 1, 0.14mmol Ni(NO 3 ) 2 ·6H 2 O was dissolved in 40 mL of deionized water. Then 1.4mmol red phosphorus was dispersed in the above 40mL containing Ni(NO 3 ) 2 ·6H 2 In the solution of O, a uniform suspension was obtained;

[0047] Step 2. Put the suspension into a 50mL steel-jacketed kettle, seal it, and keep it at 180°C for 12 hours; after the reaction is completed, cool it down to room temperature naturally, and wash the obtained precipitate alternately with deionized water and absolute ethanol for several times. Second, the final product was vacuum-dried at 60 °C to obtain 2D NPs.

Embodiment 3

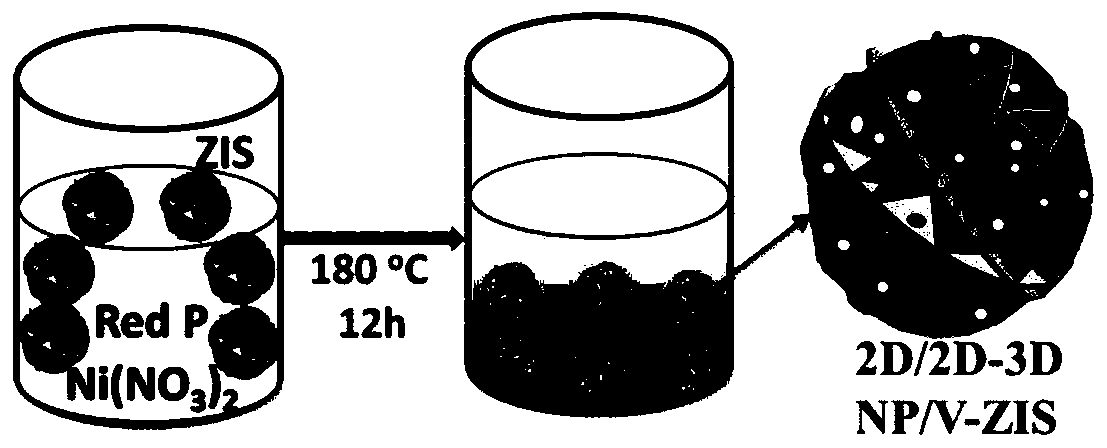

[0049] Such as image 3 As shown, this embodiment prepares 2D / 2D-3D NP / V-ZIS nanocomposites according to the following steps:

[0050] This example is the same as Example 2, except that 0.21 g of the 2D-3D ZIS prepared in Example 1 is added in Step 1. By changing the amount of nickel nitrate and red phosphorus in this example, 2D / 2D-3D NP / V-ZIS nanocomposites with different NP contents can be prepared, such as: the amounts of nickel nitrate and red phosphorus are (0.02mmol, 0.20 mmol), (0.06mmol, 0.60mmol), (0.10mmol, 1.00mmol), (0.14mmol, 1.4mmol), (0.25mmol, 2.5mmol), the mass percent composition of NP in the obtained product is respectively 1%, 3 %, 5%, 7% and 12%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com