Sub-nano AlF3 catalyst as well as preparation method and application thereof

A catalyst and sub-nanometer technology, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, dehydrohalogenation preparation, etc., can solve the problems of catalyst deactivation, etc., so as to achieve less carbon deposition and deactivation, short preparation cycle, high The effect of catalytic activity and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 6.698g of Al(NO 3 ) 3 9H 2 O and 2.586g of organic ligands were placed in a polytetrafluoroethylene liner and stirred for 30min, stirred evenly and then placed in a hydrothermal kettle for 0.5d at 160°C. Then wash with DMF and ethanol in a water bath at 60°C for 2h, and dry at 60°C for 10h to obtain white powder MIL-53-Al. Put MIL-53-Al into the atmosphere tube furnace, and feed the gas phase fluorine source CHClF at 300°C 2 , the gas phase fluorine source flow rate is 20ml / min fluorination for 1h, and then wait until the gas phase fluorination is completed, fluorination for 1h; switch the atmosphere in the tube furnace to N 2 Until the natural cooling to room temperature, the stable sub-nanometer AlF 3 catalyst. The obtained catalyst sample was sieved with a 20-40 mesh sieve.

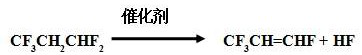

[0023] The above-prepared subnano-AlF 3 The catalyst is used to catalyze the cracking of 1,1-difluoroethane (HFC-152a) to produce vinyl fluoride. The reaction formula is as follows:

[0...

Embodiment 2

[0027] 6.698g of Al(NO 3 ) 3 9H 2 O and 2.586g of organic ligands were placed in a polytetrafluoroethylene liner and stirred for 30min, stirred evenly and then placed in a hydrothermal kettle for 3d at 220°C. Then wash with DMF and ethanol in a water bath at 80°C for 4.5h, and dry at 120°C for 24h to obtain white powder MIL-53-Al. Put MIL-53-Al into 20ml of 40wt% HF solution, put it in a water bath at 60°C for 8h with stirring, wash it by centrifugation, and dry it at 60°C to prepare the catalyst, 400°C N 2Calcined under the atmosphere for 3h and then cooled down to room temperature naturally to obtain stable sub-nanometer AlF 3 Catalyst, the obtained catalyst sample is sieved with a 20-40 mesh sieve.

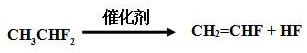

[0028] The above-prepared subnano-AlF 3 The catalyst is used to catalyze the cracking of 1,1,1,3,3-pentafluoropropane (HFC-245fa) to produce 1,3,3,3-tetrafluoropropene (HFO-1234ze), the reaction formula is as follows:

[0029]

[0030] The reaction conditions are: the ...

Embodiment 3

[0032] 6.698g of Al(NO 3 ) 3 9H 2 O and 2.586g of organic ligands were placed in a polytetrafluoroethylene liner and stirred for 30min, stirred evenly and then placed in a hydrothermal kettle for 3d at 220°C. Then wash with DMF and ethanol in a water bath at 80°C for 4.5h, and dry at 120°C for 24h to obtain white powder MIL-53-Al. 5.366g of MIL-53-Al and 13.686g of ammonium bifluoride (NH 4 HF 4 ) into the ball mill jar, and put the ball mill jar into the ball mill to fix it. The program of the ball mill is set to 400r / min, and the ball mill is suspended for 30 minutes every hour for 3 hours until the program ends. Put the ball mill jar and its milled samples into an oven for 6 h at 80°C, take out the samples, and put them in a tube furnaceN 2 Calcined at 400°C for 3 h under atmosphere. The catalyst sample was obtained and sieved with a 20-40 mesh sieve.

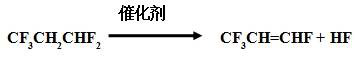

[0033] The above-prepared subnano-AlF 3 The catalyst is used to catalyze the cracking of 1,1,1,3,3-pentafluoropro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com